Stainless Steel Sheet with 321 grade 2B in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

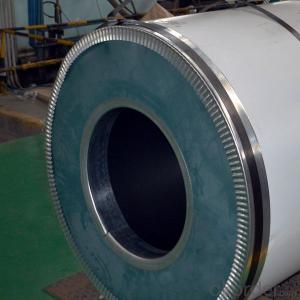

stainless steel sheet with 321 grade 2B

Features:

1.Accurate dimension

2.Minimum mainenance

3.Excellent service life

4.Non Corrosive

5.Heat Resistant

Detail information:

1. Steel grade: 321

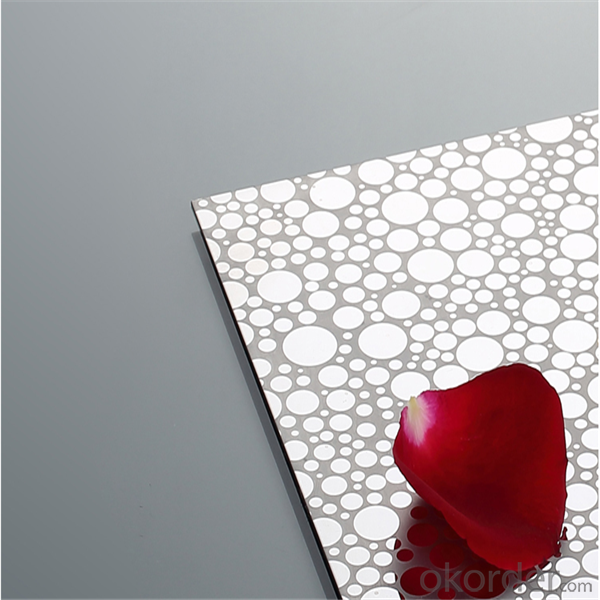

2. Surface: 2B, BA, No. 4, 8K(mirror), HL, embossing, etching. And more than 100 different patterns for your choice.

3. Colors: Golden, rose golden, titanium golden coating, champagne golden, brown, bronze, titanium black, sapphire blue, purple, gray, silver, coffee champagne, jade-green, etc.

4. Thickness: 0.3-120mm

5. Width: 500mm, 1000mm, 1219mm, 1500mm, 1800. And length: Could be cut into any size as per customer's request. Usually our common sizes: 1219mm*2438mm (4*8ft), 1219mm*3048mm (4*10ft) and 1000mm*2000mm.

6. Standard: AISI, SUS, etc.

7. Packing: Standard sea-worthy packing, cover with PVC, and wooden case, or customize package.

8. Application:

Architectural decoration, luxury doors, wall decoration plate, elevators decorating, KTV indoor decoration, metal tank shell, ship building, decoration inside the train, as well as outdoor works, advertising name plate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place, kitchen equipment, light industrial and others.

9. Advantage: Colorful, showing the splendor of your quality, wear-resistant as well, strong corrosion resistance, anti-rust property and decorative effect, durable and beautiful in good taste.

10. Supplier Product Code: SDJM

11. Competitive Advantages of the product

1) Stainless Steel Decorative Sheet

2) Customize pattern and color coating

3) Advantage: Various patterns, splendid decorative effect, fashionable design

4) Surface finish: Mirror, 2b, no.1, no.4, 6k, 8k, polished, etc

Item | stainless steel plate(Hot rolled,cold rolled) |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,etc |

Material | 310S,310,309,309S,316,316L,316Ti,317,317L,321,321H,347,347H,304,304L, 302,301,201,202,403,405,409,409L,410,410S,420,430,631,904L,Duplex,etc |

Surface | 2B,2D,BA,NO.1,NO.4,NO.8,8K,mirror,checkered,embossed,hair line,sand blast,Brush,etching,etc |

Thickness | 0.01~200mm |

Width | 1000mm,1219mm,1500mm,1800mm,2000mm,2500mm,3000mm,3500mm,etc |

Length | 2000mm,2440mm,3000mm,5800mm,6000mm,etc |

Package | Standard export package,suit for all kinds of transport,or as required. |

Container Size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 40ft HC:12032mm(Lengh)x2352mm(Width)x2698mm(High) |

Price term | Ex-Work,FOB,CNF,CFR,CIF,FCA,DDP,DDU,etc |

Payment term | TT,L/C,western Union |

Export to | Ireland,Singapore,Indonesia,Ukraine,Saudi Arabia,Spain,Canada,USA,Brazil,Thailand,Korea,Iran, India,Egypt,Oman,Malaysia,Bangladesh,Dubai,Viet Nam,Kuwait,Peru,Mexico,Russia,etc |

MOQ | 500Kg |

Application | Stainless steel plate applies to construction field, ships building industry, petroleum,chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields.Stainless steel plate can be made according to the customers requirements. |

Contact | If you have any question,please feel free to contact me . we are sure your inquiry or requirements will get prompt attention |

- Q: Can stainless steel sheets be used for automotive applications?

- Yes, stainless steel sheets can be used for automotive applications. Stainless steel is a highly versatile and durable material that offers excellent resistance to corrosion, heat, and impact. These properties make it ideal for automotive applications where durability and resistance to harsh environments are essential. Stainless steel sheets can be used in various parts of the automotive industry, including body panels, exhaust systems, fuel tanks, and even interior components. Additionally, stainless steel can be easily formed, welded, and manipulated to meet specific design requirements, making it a popular choice in the automotive industry.

- Q: What are the benefits of using textured stainless steel sheets in decorative lighting fixtures?

- There are several benefits of using textured stainless steel sheets in decorative lighting fixtures. Firstly, textured stainless steel sheets add a unique and visually appealing element to the lighting fixture. The texture creates depth and dimension, making the fixture stand out and become a focal point in any space. Whether it is a hammered, brushed, or embossed texture, it adds a touch of elegance and sophistication to the overall design. Secondly, stainless steel is a durable and long-lasting material. It is resistant to corrosion, rust, and damage caused by moisture or humidity. This makes it an ideal choice for lighting fixtures, especially in outdoor or high-moisture environments. The textured surface also helps to hide any potential scratches or marks that may occur over time, ensuring a consistently attractive appearance. Additionally, stainless steel is easy to clean and maintain. The smooth surface of the textured stainless steel sheets allows for easy removal of dirt, fingerprints, and other smudges, making it effortless to keep the lighting fixture looking polished and clean. Furthermore, stainless steel has excellent light reflectivity properties. The textured surface can enhance the way light is dispersed, creating interesting patterns and shadows. This can add a unique ambiance to the surrounding area and create a visually stunning effect. Lastly, stainless steel is a sustainable and eco-friendly material. It is 100% recyclable, making it an environmentally responsible choice for lighting fixtures. By using textured stainless steel sheets, we can contribute to reducing our carbon footprint and promoting a greener future. In conclusion, the benefits of using textured stainless steel sheets in decorative lighting fixtures are numerous. They add a visually appealing element, are durable and long-lasting, easy to clean and maintain, have excellent light reflectivity properties, and are environmentally friendly. These advantages make textured stainless steel sheets an excellent choice for creating stunning and sustainable lighting fixtures.

- Q: Can stainless steel sheets be used for hygienic environments?

- Yes, stainless steel sheets can be used for hygienic environments. Stainless steel is a popular choice for such environments due to its inherent properties that make it highly resistant to corrosion, heat, and chemical damage. Its smooth and non-porous surface is easy to clean, preventing the accumulation of bacteria, mold, or other contaminants. Stainless steel is also non-reactive and does not release any harmful substances, making it suitable for sensitive environments such as food processing facilities, hospitals, pharmaceutical labs, and cleanrooms. Additionally, stainless steel is durable and long-lasting, providing excellent hygiene and cleanliness for extended periods. Overall, stainless steel sheets are a reliable and hygienic choice for various applications in environments that prioritize cleanliness and sanitation.

- Q: What are the limitations of using stainless steel sheets?

- There are several limitations associated with using stainless steel sheets. Firstly, stainless steel sheets can be quite expensive compared to other materials. This can make it less feasible for certain budget-conscious projects or applications. Secondly, stainless steel sheets are relatively heavy, which can make them difficult to handle and install, especially in large quantities. This can increase labor costs and require additional equipment for transportation and installation. Thirdly, stainless steel sheets are prone to scratching and denting. While stainless steel is known for its durability, it is not entirely resistant to physical damage. Scratches and dents can diminish the appearance and functionality of the sheets, particularly in high-traffic areas or environments where there is a risk of impact. Additionally, stainless steel sheets can be susceptible to corrosion, although to a lesser extent compared to other metals. In certain conditions, such as exposure to saltwater or harsh chemicals, stainless steel sheets may develop rust or other forms of corrosion. Regular maintenance and proper care are necessary to prevent or minimize this issue. Another limitation is that stainless steel sheets have limited color options. They generally come in shades of silver or gray, which may not be suitable for projects that require specific colors or aesthetics. Lastly, stainless steel sheets have poor insulation properties. They conduct heat and cold more efficiently than other materials, which can result in greater energy loss and higher heating or cooling costs. In applications where insulation is crucial, additional measures or alternative materials may be required. In conclusion, while stainless steel sheets offer numerous advantages such as strength, corrosion resistance, and durability, they also have limitations in terms of cost, weight, susceptibility to damage, corrosion, limited color options, and poor insulation properties. Understanding these limitations is crucial when considering the use of stainless steel sheets in various applications.

- Q: Can stainless steel sheets be used for railway infrastructure?

- Yes, stainless steel sheets can be used for railway infrastructure. Stainless steel is a versatile and durable material that offers various advantages for railway applications. Its corrosion resistance properties make it suitable for outdoor and high humidity environments, which are common in railway infrastructure. Stainless steel sheets can withstand harsh weather conditions, including extreme temperatures, rain, and UV radiation, without corroding or deteriorating. This makes them ideal for railway tracks, bridges, tunnels, and other structures that are exposed to the elements. Additionally, stainless steel sheets have excellent strength-to-weight ratio, allowing for the construction of lightweight yet sturdy railway infrastructure. This reduces the load on the overall structure and facilitates easier transportation and installation. Stainless steel is also resistant to fire and can withstand high impact, making it a reliable choice for railway applications where safety is a priority. Furthermore, stainless steel sheets are easy to clean and maintain, which is beneficial for railway infrastructure that requires regular upkeep. They can be easily polished to restore their aesthetic appeal and maintain a clean appearance. Stainless steel is also recyclable, making it an environmentally friendly choice for sustainable railway construction. In summary, stainless steel sheets can indeed be used for railway infrastructure due to their corrosion resistance, strength, durability, fire resistance, ease of maintenance, and sustainability.

- Q: Are stainless steel sheets suitable for heat transfer equipment?

- Yes, stainless steel sheets are suitable for heat transfer equipment. Stainless steel has excellent thermal conductivity properties, which means it can efficiently transfer heat from one medium to another. It can withstand high temperatures without warping or deforming, making it ideal for use in heat transfer applications. Additionally, stainless steel is corrosion-resistant, ensuring the longevity and durability of the equipment. Its hygienic properties also make it suitable for industries where cleanliness is crucial, such as food and pharmaceutical industries. Overall, stainless steel sheets are a reliable and efficient choice for heat transfer equipment.

- Q: What's the drill for stainless steel?

- Stainless steel is characterized by high toughness, easy to stick the knife, so requires higher hardness of the drill bit, surface finish is better, the drill tip angle than the ordinary drill (130--135 degrees). At the same time, cooling should be sufficient

- Q: Are stainless steel sheets resistant to pitting and crevice corrosion?

- Yes, stainless steel sheets are highly resistant to pitting and crevice corrosion due to their chromium content, which forms a protective passive layer on the surface, preventing corrosion from occurring.

- Q: Inspection method for stainless steel welding

- The position of the welding is measured by hand, beat, shake, push and push. The sensing effect of the component is tested. The welding should be firm and reliable, and the strength of each component is required to meet the requirements of the strength of each component. Not false welding, weld and weld loose crack,

- Q: What's the surface of the 304 stainless steel matte board?

- NO.2B gloss is stronger than NO.2D NO.2D, after processing, through the polishing roller, eventually a slight cold rolling, in order to obtain proper luster. This is the most commonly used surface finish, which can also be used as the first step in polishing. General timberBA is bright as a mirror but has no standard, but is usually bright annealed and has a high surface reflectivity. Building materials, Kitchenware

Send your message to us

Stainless Steel Sheet with 321 grade 2B in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords