Stainless Steel Sheets With Good Quality Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

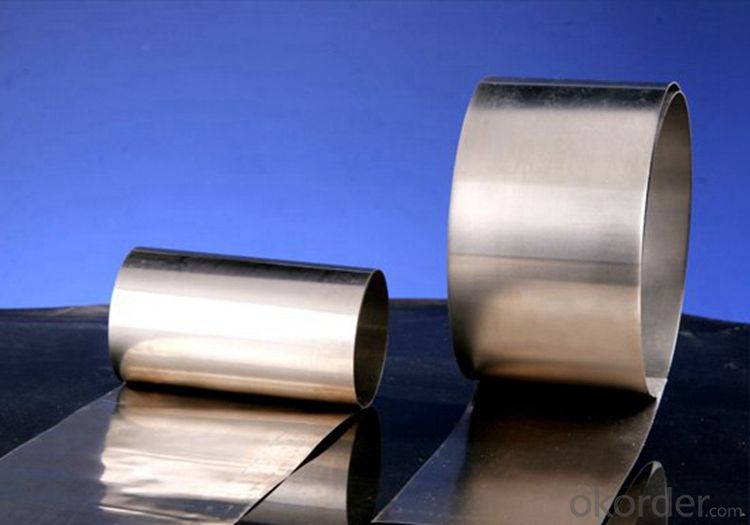

Detail picture for Stainless Steel Coils/Sheets

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: How do you prevent fingerprints and smudges on stainless steel sheets?

- To avoid fingerprints and smudges on stainless steel sheets, several effective techniques can be employed: 1. Opt for a microfiber cloth: Employ a soft microfiber cloth to gently wipe the stainless steel surface. Microfiber is gentle and will not cause any scratches or streaks. Avoid using rough materials such as paper towels or abrasive sponges. 2. Utilize a stainless steel cleaner: Invest in a high-quality stainless steel cleaner that is specifically designed to eliminate fingerprints and smudges. Adhere to the cleaner's instructions and evenly apply it to the surface using a cloth or sponge. Remove any excess cleaner with a clean cloth. 3. Apply baby oil or mineral oil: Dab a small amount of baby oil or mineral oil onto a cloth and delicately rub it over the stainless steel surface. This will create a thin protective layer that aids in preventing fingerprints and smudges from adhering to the metal. 4. Avoid direct contact with bare hands: Fingerprints and smudges often result from direct contact with hands. Endeavor to handle stainless steel sheets with clean, dry hands or wear gloves if necessary. This will minimize the transfer of oils and residue onto the surface. 5. Establish a regular cleaning routine: Implement a consistent cleaning regimen for your stainless steel sheets. Wipe them down with a microfiber cloth or stainless steel cleaner at least once a week, or more frequently in high-traffic areas. This will hinder the accumulation of oils and grime, thereby reducing the likelihood of fingerprints and smudges. By adhering to these methods, you can effectively thwart the occurrence of fingerprints and smudges on stainless steel sheets, preserving their cleanliness and shine for an extended duration.

- Q: What does stainless steel sheet S2 stand for?

- Stainless steel sheet S2 stands for thickness 2mm

- Q: Can stainless steel sheets be used in high-temperature environments?

- Yes, stainless steel sheets can be used in high-temperature environments. Stainless steel is known for its excellent heat resistance properties, making it suitable for various applications in high-temperature environments. The specific grade of stainless steel used and its composition determines its maximum operating temperature. Austenitic stainless steels, such as grades 304 and 316, can withstand temperatures up to 1600°F (870°C) without losing their mechanical strength or corrosion resistance. However, higher alloyed stainless steels, such as grades 309 and 310, are specifically designed to handle even higher temperatures, up to around 2100°F (1150°C). These stainless steel sheets are commonly used in industries like power generation, chemical processing, furnace manufacturing, and aerospace, where exposure to extreme heat is a requirement.

- Q: What is the density of stainless steel sheets?

- The density of stainless steel sheets typically ranges from 7.9 to 8.0 grams per cubic centimeter.

- Q: Can stainless steel sheets be used in manufacturing processes?

- Yes, stainless steel sheets can be used in manufacturing processes. Stainless steel is a versatile material known for its corrosion resistance, durability, and strength. It is commonly used in various manufacturing industries such as automotive, construction, aerospace, and food processing. Stainless steel sheets can be fabricated, formed, and shaped to meet specific requirements, making them suitable for a wide range of manufacturing applications.

- Q: Can stainless steel sheets be used for athletic equipment?

- Yes, stainless steel sheets can be used for athletic equipment. Stainless steel is known for its durability, corrosion resistance, and high strength, making it suitable for various applications in the sports industry. It is commonly used for equipment like weightlifting bars, exercise machines, and outdoor sports structures due to its ability to withstand heavy use and exposure to different weather conditions.

- Q: What are the common sizes and thicknesses of stainless steel sheets?

- The common sizes and thicknesses of stainless steel sheets vary depending on their intended use. However, some common sizes range from 4 feet by 8 feet to 5 feet by 10 feet, while thicknesses can range from 0.4 mm to 6 mm.

- Q: What are the different types of mirror finishes available for stainless steel sheets?

- Stainless steel sheets offer a variety of mirror finishes, each with its own distinct look and reflectivity level. The most commonly used mirror finish is the #8 Mirror Finish. It boasts a highly polished surface that resembles a mirror, providing exceptional clarity and reflectivity. Achieving this finish involves using progressively finer grit abrasive compounds during the polishing process. If you're looking for a slightly less reflective option, the #7 Mirror Finish is a great choice. It still offers a high level of reflectivity and showcases a smooth, shiny surface with minimal distortion. For a moderately reflective surface with a slightly duller appearance, consider the #6 Mirror Finish. This finish hides minor surface imperfections while providing good reflectivity. It's often used in architectural applications that require a balance between reflectivity and durability. If you prefer a more subtle and sophisticated look, the Satin Mirror Finish is perfect. It features a satin-like appearance with a brushed texture, resulting in a low level of reflectivity. This finish is commonly used in decorative applications like interior design or furniture. For a vintage or aged appearance, the Antique Mirror Finish is ideal. It involves applying special chemical treatments to the stainless steel surface, creating a reflective surface with a distorted and tarnished look. This finish adds a unique and artistic touch to various applications. Ultimately, the decision on which mirror finish to choose depends on your desired level of reflectivity, aesthetic preferences, and the specific requirements of your application.

- Q: What is the difference between 304 and 316 stainless steel sheets?

- 304 and 316 stainless steel sheets are both popular choices for a wide range of applications due to their excellent corrosion resistance and durability. However, there are some key differences between the two. Firstly, the most noticeable distinction is the composition of these stainless steel alloys. 304 stainless steel contains 18% chromium and 8% nickel, while 316 stainless steel contains 16% chromium, 10% nickel, and 2% molybdenum. This additional molybdenum in 316 stainless steel provides enhanced resistance to corrosion, especially in chloride-rich environments such as marine or coastal areas. Therefore, 316 stainless steel is often preferred for applications where exposure to harsh conditions or corrosive chemicals is expected. Secondly, the higher nickel and molybdenum content in 316 stainless steel make it more resistant to pitting and crevice corrosion, which can occur in stagnant or low-oxygen environments. This makes 316 stainless steel a better choice for applications involving prolonged exposure to acidic or alkaline solutions, such as chemical processing plants or medical equipment. Thirdly, the higher molybdenum content in 316 stainless steel also improves its resistance to high temperatures. It can withstand higher temperatures than 304 stainless steel, making it suitable for applications involving heat exposure, such as exhaust systems or boilers. Lastly, 316 stainless steel is generally more expensive than 304 stainless steel due to its higher alloy content. However, the added benefits and increased corrosion resistance of 316 stainless steel may justify the higher cost in certain applications where performance and longevity are crucial. In summary, while both 304 and 316 stainless steel sheets offer excellent corrosion resistance, 316 stainless steel provides superior resistance to harsh environments, acidic or alkaline solutions, and higher temperatures due to its higher nickel, chromium, and molybdenum content. The choice between the two will depend on the specific application and the level of corrosion resistance required.

- Q: Can stainless steel sheets be used for heat shields?

- Certainly! Heat shields can indeed utilize stainless steel sheets. Renowned for their exceptional heat resistance and durability, stainless steel proves to be an outstanding option for safeguarding against heat transfer. By effectively deflecting radiant, convective, and conductive heat, stainless steel sheets are well-suited for an array of purposes, encompassing automotive heat shields, industrial machinery, and household appliances. Moreover, their corrosion resistance and effortless maintenance render stainless steel sheets a pragmatic and enduring selection for heat shield implementations.

Send your message to us

Stainless Steel Sheets With Good Quality Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords