Stainless Steel Sheet Price Per Ton Per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Specifications about stainless steel sheet

Commodity | China supplier 3mm thickness ba finished stainless steel sheet price 309 |

Grade | 201,202,304,304L,316,316L,317L,310S,321,904L,409s,410,430 |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.3-100mm or as customer’s requirement |

Width | 500-3000mm or as customer’s requirement |

Length | 1000-6000mm or as customer’s requirement |

Surface | No.1 / No.4 / BA / 2B/HL/mirror/polished/brushed(bright annealed, surface not oxidati and brighter) |

Standard | JIS,AISI,ASTM,GB,DIN |

Delivery time | About10 days |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

Attention: the specifications can be customized .

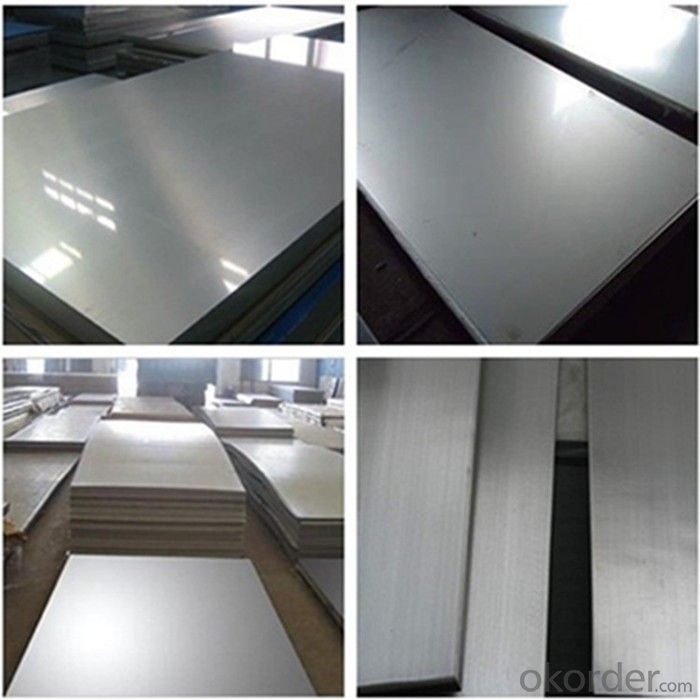

Product ShowStainless Steel Sheet Price Per Ton Per kg

Packaging & ShippingStainless Steel Sheet Price Per Ton Per kg

SurfaceStainless Steel Sheet Price Per Ton Per kg

Surface | Definition | Application |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

NO.3 | Those finished by polishing with No.100 to No.120 abravise specifiled in JIS R6001. | Kitchen utensils, Building construction |

NO.4 | Those finished by polishing with No.150 to No.180 abravise specifiled in JIS R6001. | Kitchen utensils, Building construction, Medical equipment |

HL | Those finished polishing so as to continuous polishing steaks by using abravise of suitable grain size. | Building construction |

BA(NO.6) | Those processed with bright treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction |

Mirror(NO.8) | Shinning like a mirror. | Building construction |

Application

- Q: Are stainless steel sheets suitable for structural applications?

- Yes, stainless steel sheets are suitable for structural applications. Stainless steel is a versatile and durable material that offers a high strength-to-weight ratio, making it ideal for various structural applications. It offers excellent corrosion resistance, which is important for structures that are exposed to harsh environments or chemicals. Stainless steel sheets can be used in the construction of bridges, buildings, and other structural components where strength and durability are necessary. Additionally, stainless steel is a sustainable material as it is 100% recyclable, further enhancing its suitability for structural applications.

- Q: What are the different types of stainless steel sheet finishes for architectural applications?

- Some of the different types of stainless steel sheet finishes for architectural applications include brushed, polished, mirrored, embossed, and patterned finishes. Each finish offers a distinct aesthetic and texture, allowing architects to choose the most suitable option based on their design requirements.

- Q: How do you prevent intergranular corrosion on stainless steel sheets?

- Intergranular corrosion, which causes structural damage and reduced strength, occurs along the grain boundaries of stainless steel. To prevent this corrosion on stainless steel sheets, several steps can be taken: 1. Material Selection: To prevent intergranular corrosion, it is crucial to select the appropriate grade of stainless steel. Grades like 304L or 316L, which have low carbon content, are less susceptible to this type of corrosion due to their reduced sensitivity to sensitization. 2. Heat Treatment: One can heat treat stainless steel sheets to eliminate carbide precipitation, a common cause of intergranular corrosion. This process, known as solution annealing or sensitization heat treatment, involves heating the material to a specific temperature range and rapidly cooling it. This treatment ensures the formation of a consistent and corrosion-resistant microstructure. 3. Passivation: Passivation is a chemical process that removes contaminants and forms a protective oxide layer on the surface of stainless steel sheets. This layer acts as a barrier against corrosion and prevents intergranular attack. Typically, nitric acid or citric acid solutions are used for passivation. 4. Welding Techniques: Proper welding techniques should be employed when welding stainless steel sheets to minimize the risk of intergranular corrosion. This includes using low heat input, preventing excessive heat build-up, and using filler materials with low carbon content to prevent sensitization. 5. Avoiding Contamination: It is essential to protect stainless steel sheets from contamination by other metals, particularly those with higher galvanic potentials. Contact with carbon steel, for instance, can lead to galvanic corrosion and promote intergranular attack. Therefore, it is important to store and fabricate stainless steel sheets separately from other metals. 6. Regular Cleaning and Maintenance: Regularly cleaning and maintaining stainless steel sheets is vital to prevent the accumulation of corrosive substances or contaminants on the surface. Non-abrasive cleaners and proper cleaning methods should be used to avoid scratching the stainless steel, as scratches can create sites for corrosion initiation. By implementing these preventive measures, one can significantly reduce intergranular corrosion, ensuring the durability and performance of stainless steel sheets.

- Q: How do you prevent fingerprints on stainless steel sheets?

- There are several steps you can take to prevent fingerprints on stainless steel sheets: 1. Start by thoroughly cleaning the surface of the stainless steel sheets using a mild detergent or stainless steel cleaner. This will eliminate any existing fingerprints or smudges. 2. When handling the sheets, wear gloves to avoid transferring natural oils from your hands onto the surface. Cotton or nitrile gloves are recommended as they offer a good grip and leave no residue. 3. Minimize direct contact with the stainless steel surface as much as possible. This can be achieved by using specialized tools or wearing gloves when handling and installing the sheets. 4. Consider applying a protective coating specifically designed for stainless steel. These coatings create a barrier that repels fingerprints and simplifies the cleaning process. Be sure to follow the manufacturer's instructions for proper application. 5. Use a soft microfiber cloth when cleaning the stainless steel sheets. Microfiber is gentle on the surface and helps prevent streaks and fingerprints. Avoid using abrasive materials or rough scrubbers that can damage the stainless steel finish. 6. Establish a regular cleaning routine to remove any fingerprints or smudges that may appear over time. Dilute a mild detergent in warm water and use a soft cloth or sponge to wipe down the stainless steel sheets. Rinse with clean water and thoroughly dry. By following these preventive measures and cleaning techniques, you can significantly reduce the visibility of fingerprints on stainless steel sheets and keep them looking clean and flawless.

- Q: Are stainless steel sheets suitable for water tanks?

- Stainless steel sheets are indeed a great option for water tanks. Their resistance to corrosion makes them perfect for water storage. They won't react with the water or introduce any harmful substances into it. Additionally, stainless steel tanks are durable, require little maintenance, and have a long lifespan. They can handle high temperatures and extreme weather conditions without compromising their structural integrity. Moreover, stainless steel is non-porous, preventing the growth of bacteria and algae. These outstanding characteristics make stainless steel sheets a superb choice for water tanks in different settings, such as residential, commercial, and industrial environments.

- Q: Are stainless steel sheets resistant to pitting and crevice corrosion?

- Yes, stainless steel sheets are generally resistant to pitting and crevice corrosion. Stainless steel is known for its high corrosion resistance due to the presence of chromium, which forms a passive oxide layer on the surface of the material, protecting it from corrosion. This oxide layer acts as a barrier, preventing the penetration of corrosive substances that could cause pitting and crevice corrosion. However, it is important to note that the resistance to pitting and crevice corrosion can vary depending on the specific grade of stainless steel and the environmental conditions in which it is exposed. Some grades of stainless steel, such as 316 or 317, have enhanced resistance to these types of corrosion. In addition, certain aggressive environments, such as those with high chloride concentrations or acidic conditions, can still pose a risk to stainless steel and may require the use of more corrosion-resistant grades or additional protective measures. Overall, stainless steel sheets are highly resistant to pitting and crevice corrosion, but the specific grade and environmental factors should be considered for optimal performance.

- Q: Are stainless steel sheets suitable for outdoor staircases?

- Yes, stainless steel sheets are suitable for outdoor staircases. Stainless steel is a durable material that is resistant to corrosion and extreme weather conditions, making it an excellent choice for outdoor applications. Additionally, stainless steel sheets can be easily cleaned and maintained, ensuring their longevity and aesthetic appeal.

- Q: Are stainless steel sheets suitable for food display cases?

- Yes, stainless steel sheets are highly suitable for food display cases. They have excellent hygiene properties, as they are resistant to corrosion and can be easily cleaned and sanitized. Stainless steel is also durable and can withstand frequent use and exposure to various temperatures. Additionally, its sleek and modern appearance adds an attractive and professional look to food display cases.

- Q: Can stainless steel sheets be used for stairs and railings?

- Yes, stainless steel sheets can be used for stairs and railings. Stainless steel is a durable and corrosion-resistant material that is commonly used for architectural purposes, including stairs and railings. Its strength and aesthetic appeal make it suitable for both indoor and outdoor applications.

- Q: What is the fatigue strength of stainless steel sheets?

- The fatigue strength of stainless steel sheets may differ based on various factors, including the specific grade of stainless steel, the manufacturing process, the surface finish, and the testing conditions. Generally, stainless steel sheets exhibit high fatigue strength due to their inherent properties, such as their ability to withstand cyclic loading and their resistance to corrosion. Typically, the fatigue strength of stainless steel sheets is measured in terms of stress amplitude (σa) or stress range (σr), indicating the level of stress the material can endure for a specific number of cycles before failure. Fatigue testing is often conducted to determine this, involving subjecting the material to repeated cyclic loading until it fails. The number of cycles required for failure is referred to as the fatigue life. Different grades of stainless steel possess varying fatigue strengths, with higher grades usually demonstrating greater resistance to fatigue. Austenitic stainless steels like 304 and 316, for example, exhibit excellent fatigue strength and are commonly employed in applications with significant cyclic loading, including structural components and automotive parts. The fatigue strength of stainless steel sheets can also be impacted by surface finish. Inadequate surface conditions, such as scratches, notches, or roughness, can act as stress concentrators and decrease fatigue strength. Hence, it is essential to ensure that stainless steel sheets possess a smooth and defect-free surface to maximize their resistance to fatigue. Additionally, environmental factors like temperature, humidity, and corrosive substances can influence the fatigue strength of stainless steel sheets. Elevated temperatures and aggressive environments can decrease the fatigue life of stainless steel. Therefore, it is crucial to consider these factors when designing for fatigue resistance. To summarize, the fatigue strength of stainless steel sheets is generally high due to their inherent properties. However, it can vary depending on factors such as the grade of stainless steel, surface finish, and environmental conditions. Conducting fatigue testing and considering these factors during the design process can help guarantee the optimal performance and durability of stainless steel sheets in applications involving cyclic loading.

Send your message to us

Stainless Steel Sheet Price Per Ton Per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords