321 Stainless Steel Sheet price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

321 stainless steel price per kg

1.Grade:304,304L,316,316L,309S,310S,904L,etc

2.Finish:2B,BA,HL,Brush,NO.1,NO.4,Mirror and so on.

3.Standards:JIS,AISI,ASTM,GB

4.Thick;0.3mm--150mm

5.Wide;1000mm--2000mm

6.Length;1000mm--6000mm

7.Packing: standard export sea-worthy packing or as the customers’ requirement

8.Payment:L/C and T/T

9.Shipment:about 10 days after payment terms.

10.Trade Terms:FOB Shanghai.

11.Application construction, building, kitchwares, medical industry, eletricity industry and so on.

We have very good connection with factory, so we can provide competitive price to you, if u are intresented in our products, pls feel free to contract us.

Your enquiry will be welcome.

Details:

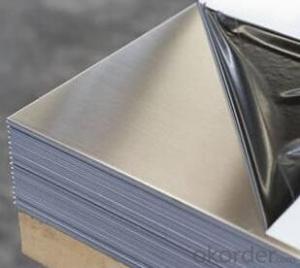

Type | Stainless steel sheet(cold rolled or hot rolled) |

Thinckness | 0.3mm - 150mm or as customer's requirement |

Widthness | 1000mm - 2000mm or as customer's requirement |

Length | 1000mm - 6000mm or as customer's requirement |

Finish | 2B,BA,HL,Brush,NO.1,NO.4,Mirror and so on. |

Standard | JIAISI, ASTM, GB, |

Material | 304, 304L, 316, 316L, 309S, 310S, 321, etc |

Application range | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum,boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | About 7 days after the order |

Quality | Prime |

Productivity | 500 tons/week |

Note | Other standards can be produced as the customers’ requirement |

- Q: Are stainless steel sheets suitable for automotive body panels?

- Absolutely! Automotive body panels can definitely benefit from the use of stainless steel sheets. This material is widely favored in the automotive industry because of its remarkable ability to resist corrosion and its exceptional durability. It can withstand even the harshest weather conditions, making it perfect for body panels. Moreover, stainless steel sheets provide a sleek and polished look, enhancing the overall aesthetic appeal of the vehicle. Furthermore, stainless steel offers a superior strength-to-weight ratio, resulting in better fuel efficiency and improved vehicle performance. In conclusion, stainless steel sheets are an incredibly reliable and long-lasting choice for automotive body panels.

- Q: What are the standard sizes of stainless steel sheets?

- The standard sizes of stainless steel sheets can vary depending on the specific requirements and applications. However, common standard sizes for stainless steel sheets include 4 feet by 8 feet, 4 feet by 10 feet, and 5 feet by 10 feet. Other sizes may also be available based on customer needs and supplier capabilities.

- Q: Can stainless steel sheets be used for cladding?

- Yes, stainless steel sheets can be used for cladding. Stainless steel is a popular choice for cladding due to its durability, corrosion resistance, and aesthetic appeal. It is commonly used in exterior cladding applications for buildings, such as facades, canopies, and curtain walls. Stainless steel sheets provide a sleek and modern appearance while offering protection against harsh environmental conditions. Additionally, stainless steel cladding is low maintenance, long-lasting, and can be easily cleaned, making it a practical choice for both residential and commercial applications.

- Q: Can stainless steel sheets be used for marine propellers?

- Yes, stainless steel sheets can be used for marine propellers. Stainless steel is a popular choice for marine propellers due to its excellent corrosion resistance properties. The high levels of chromium in stainless steel make it resistant to rust and other forms of corrosion, even in saltwater environments. Additionally, stainless steel offers good strength and durability, making it suitable for withstanding the harsh conditions of marine environments. Stainless steel propellers are often preferred for boats and ships as they require less maintenance and have a longer lifespan compared to other materials. However, it is important to choose the appropriate grade of stainless steel for marine propellers to ensure optimal performance and longevity.

- Q: What are the different types of edge finishes available for stainless steel sheets?

- There are several types of edge finishes available for stainless steel sheets, including the straight edge, beveled edge, rounded edge, and hemmed edge.

- Q: Can stainless steel sheets be used in manufacturing processes?

- Yes, stainless steel sheets can be used in manufacturing processes. Stainless steel is a versatile material known for its corrosion resistance, durability, and strength. It is commonly used in various manufacturing industries such as automotive, construction, aerospace, and food processing. Stainless steel sheets can be fabricated, formed, and shaped to meet specific requirements, making them suitable for a wide range of manufacturing applications.

- Q: Can stainless steel sheets be used for outdoor signage?

- Indeed, outdoor signage can be made using stainless steel sheets. This material, known for its durability and resistance to corrosion, remains unscathed in challenging weather conditions while preserving its visual appeal. Its widespread use in outdoor signage can be attributed to its ability to withstand rust, fading, and harm caused by sunlight, rain, snow, and other environmental factors. Moreover, stainless steel sheets can be personalized with different finishes like brushed or polished, enhancing their aesthetic allure and making them suitable for any outdoor signage requirement.

- Q: What is the difference between stainless steel sheets and regular steel sheets?

- Stainless steel sheets and regular steel sheets differ primarily in their composition and properties. Stainless steel sheets are made primarily of iron and contain a minimum of 10.5% chromium, which gives them their unique stainless properties. Regular steel sheets, on the other hand, are made primarily of iron and carbon, with no significant amount of chromium. The presence of chromium in stainless steel sheets provides several distinct advantages. Firstly, it enhances the corrosion resistance of the material, making it highly resistant to rust and staining. This makes stainless steel sheets suitable for applications in environments where moisture or exposure to corrosive substances is a concern, such as in the food and beverage industry or marine applications. Additionally, stainless steel sheets have excellent heat resistance, making them suitable for high-temperature applications. They can withstand extreme temperatures without losing their structural integrity, which regular steel sheets may not be able to tolerate. Another key difference lies in the appearance of the two materials. Stainless steel sheets have a bright, reflective surface due to their chromium content, giving them a lustrous and modern look. Regular steel sheets, on the other hand, have a duller and less polished appearance. Furthermore, stainless steel sheets are often more expensive than regular steel sheets due to the additional manufacturing processes and the higher cost of the chromium alloy. However, the enhanced corrosion resistance and durability provided by stainless steel sheets can often justify the higher cost in various applications. In summary, stainless steel sheets differ from regular steel sheets in terms of their composition, properties, appearance, and cost. Stainless steel sheets offer superior corrosion resistance, heat resistance, and a visually appealing surface, making them ideal for specific applications where these attributes are required. Regular steel sheets, on the other hand, are more affordable but lack the unique properties of stainless steel.

- Q: Inspection method for stainless steel welding

- The position of the welding is measured by hand, beat, shake, push and push. The sensing effect of the component is tested. The welding should be firm and reliable, and the strength of each component is required to meet the requirements of the strength of each component. Not false welding, weld and weld loose crack,

- Q: Can stainless steel sheets be used for storage tanks?

- Indeed, storage tanks can absolutely utilize stainless steel sheets. Stainless steel possesses a remarkable level of resistance to corrosion, rendering it an excellent material for the storage of a wide range of substances, such as chemicals, liquids, and gases. Its exceptional durability guarantees an extended lifespan for the storage tank, thereby minimizing the likelihood of leaks or contamination. Moreover, stainless steel tanks are effortless to clean and maintain, making them particularly suitable for industries like food and beverage, pharmaceuticals, and wastewater treatment. Furthermore, stainless steel is non-reactive, meaning it does not react with the stored substances, thus ensuring the integrity and quality of the materials being stored. All in all, stainless steel sheets serve as a dependable and versatile option for storage tank applications.

Send your message to us

321 Stainless Steel Sheet price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords