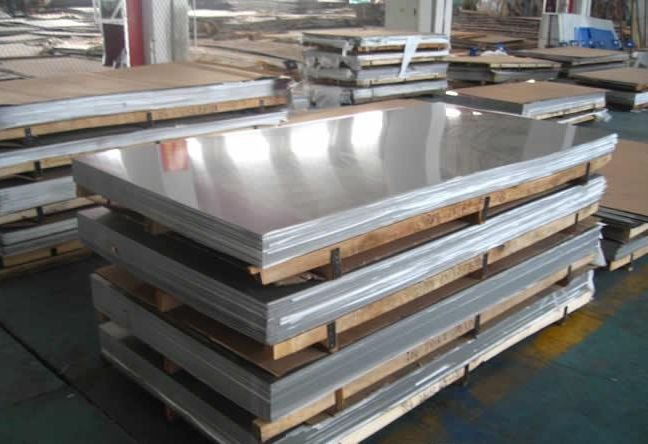

TISCO China 310S Stainless Steel Plate price per ton

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

| Product: | 310S sheet&plate | |

| Grade: | 304,304L,321,321H,316,316L,317L,310S | |

| Specifications: | Length | 2000-6000mm, or according to customer’s requirement. |

| Width | 32mm-2200mm, or according to customer’s requirement. | |

| Thickness | 0.25-100mm, or according to customer’s requirement. | |

| Standard: | ASTM, GB, JIS, DIN, ASME, etc. | |

| Surface finish: | No. 2B, No. 3, No.4,BA | |

| Application: | construction field, building industry, petroleum & chemical industries, machinary, hardware fields, and so on. | |

| Package detail: | Wraps with kraft paper, steel strip bundled, wooden matting, or as per customers' requirements | |

| Delivery time: | Within 15 days | |

| Payment terms | T/T in advance and the balance by LC | |

| Advantages: | Strong corrosion and decorative effect. | |

| Main product chemical composition |

Grade | C % | Si % | Mn % | P % | S % | Cr % | Mo % | Ni % | Other % |

201 | ≤0.15 | ≤1.00 | 5.5-7.5 | ≤0.06 | ≤0.03 | 16-18 | - | 3.5-5.5 | N≤0.25 |

202 | ≤0.15 | ≤1.00 | 7.5-10.0 | ≤0.06 | ≤0.03 | 17-19 | - | 4.0-6.0 | N≤0.25 |

301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16-18 | - | 6.0-8.0 | - |

302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17-19 | - | 8-10.0 | - |

303 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.2 | ≥0.015 | 17-19 | ≤0.6 | 8.0-10.0 | - |

304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18-20 | - | 8-10.5 | - |

304L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18-20 | - | 9-13 | - |

309S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 22-24 | - | 12-15 | - |

310S | ≤0.08 | ≤1.5 | ≤2.00 | ≤0.045 | ≤0.03 | 24-26 | - | 19-22 | - |

316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16-18 | 2-3 | 10-14 | - |

316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 16-18 | 2-3 | 12-15 | - |

317 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 18-20 | 3-4 | 11-15 | - |

321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 17-19 | - | 9-13 | Ti≥5×C |

430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.04 | ≤0.03 | 16-18 | - | ≤0.6 |

- Q: Are stainless steel sheets resistant to hydrochloric acid?

- Yes, stainless steel sheets are generally resistant to hydrochloric acid. Stainless steel is known for its high corrosion resistance, and it has been found to withstand a wide range of acids, including hydrochloric acid. However, the level of resistance can vary depending on the grade and composition of the stainless steel. In some cases, prolonged exposure to concentrated hydrochloric acid or high temperatures can cause corrosion or damage. Therefore, it is recommended to consult with a stainless steel specialist or refer to the specific stainless steel grade's corrosion resistance chart to determine the suitability of stainless steel sheets for a particular application involving hydrochloric acid.

- Q: How do you remove oil stains from stainless steel sheets?

- To remove oil stains from stainless steel sheets, you can start by wiping the surface with a clean, soft cloth dampened with warm water and mild dish soap. If the stain persists, apply a small amount of vinegar or rubbing alcohol onto the cloth and gently rub the affected area. Rinse with water and dry thoroughly to avoid water spots.

- Q: How do you remove rust or corrosion from stainless steel sheets?

- In order to eliminate rust or corrosion from stainless steel sheets, the following steps can be followed: 1. Initiate the process by cleansing the surface of the stainless steel sheet using a mild detergent and warm water. This will eradicate any dirt or grease that may potentially impede the rust removal procedure. 2. Subsequently, ensure the sheet is thoroughly dried to prevent any further water damage and to guarantee the effectiveness of the rust removal process. 3. Proceed by utilizing a non-abrasive scrubbing pad or a soft cloth to apply a stainless steel cleaner or a homemade solution comprising equal parts vinegar and water. Gently rub the affected area in the direction of the grain of the stainless steel. 4. If the rust or corrosion persists, experiment with a paste formed from baking soda and water or a mixture of cream of tartar and water. Apply this paste to the affected region and allow it to sit for approximately 15 minutes. Then, delicately scrub the area with a soft cloth or a non-abrasive scrubbing pad. 5. If the aforementioned methods do not completely eliminate the rust or corrosion, consider using a commercial rust remover specifically formulated for stainless steel. Make sure to adhere to the manufacturer's instructions and adopt suitable safety precautions. 6. Once the rust or corrosion has been eradicated, rinse the stainless steel sheet thoroughly with clean water and completely dry it to prevent any water spots or further damage. 7. To prevent future rust or corrosion, it is advisable to regularly clean and maintain stainless steel surfaces using non-abrasive cleaners and avoiding harsh chemicals or abrasive materials. Always remember to conduct a test of any cleaning solution or rust remover on a small and inconspicuous area of the stainless steel sheet prior to applying it to the entire surface, to ensure it does not cause any damage or discoloration.

- Q: Can stainless steel sheets be painted or coated?

- Yes, stainless steel sheets can be painted or coated. However, it is important to properly prepare the surface by cleaning and applying a suitable primer before painting or coating to ensure adhesion and durability of the finish.

- Q: Are stainless steel sheets suitable for medical implants?

- Yes, stainless steel sheets are suitable for medical implants. Stainless steel is commonly used in medical implants due to its excellent corrosion resistance, mechanical strength, and biocompatibility. It can be easily sterilized, is durable, and has a long track record of successful use in various medical applications.

- Q: 304 stainless steel has several advantages, a few big advantages, the more concrete the better

- 304 stainless steel has excellent stainless steel corrosion resistance and better intergranular corrosion resistance. The oxidizing acid, in the experiments: the concentration of more than 65% of boiling temperature following nitrate, 304 stainless steel has high corrosion resistance. Alkaline solution and most organic acids and inorganic acids also have good corrosion resistance.

- Q: How do you remove fingerprints from brushed stainless steel sheets?

- To remove fingerprints from brushed stainless steel sheets, you can use a microfiber cloth or a soft cloth dampened with warm soapy water to gently wipe away the fingerprints. Avoid using abrasive cleansers or scrub brushes as they can damage the brushed finish. Dry the surface thoroughly with a clean cloth to prevent water spots.

- Q: Are stainless steel sheets resistant to lactic acid?

- Yes, stainless steel sheets are generally resistant to lactic acid.

- Q: Can stainless steel sheets be used for swimming pool construction?

- Yes, stainless steel sheets can be used for swimming pool construction. Stainless steel is a durable and corrosion-resistant material, making it suitable for withstanding the harsh conditions of a swimming pool environment. It is commonly used for constructing pool walls, floors, and other structural components.

- Q: What kind of screws do you choose for stainless steel plates?

- If it's a fixed plate, ordinary ones will doOf course, stainless steel screws are the best

Send your message to us

TISCO China 310S Stainless Steel Plate price per ton

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords