Stainless Steel Sheet for Multi Fields Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet for Multi Fields Applications

Description of Stainless Steel Sheet for Multi Fields Applications:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of Stainless Steel Sheet for Multi Fields Applications:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Maintance of Stainless Steel Sheet for Multi Fields Applications:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Applications of Stainless Steel Sheet for Multi Fields Applications:

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many applications. There are over 150 grades of stainless steel, of which fifteen are most commonly used. The alloy is milled into coils, sheets, plates, bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipment Storage tanks and tankers used to transport orange juice and other food are often made of stainless steel, because of its corrosion resistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steamcleaned and sterilized and does not need paint or other surface finishes..

Specifications of Stainless Steel Sheet for Multi Fields Applications:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics of Stainless Steel Sheet for Multi Fields Applications:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

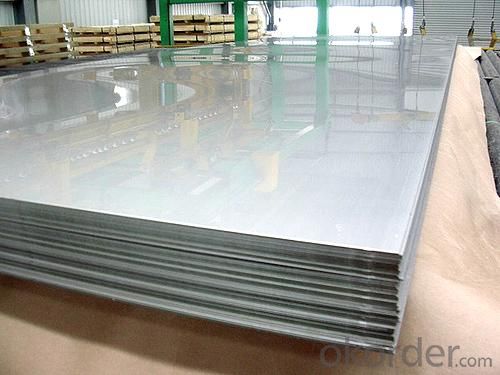

Images of Stainless Steel Sheet for Multi Fields Applications:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

Our company adheres to the tenet of "survival by quality, build brand by reputation, win market by prices and innovate to develop", has developed international markets and the products are well sold in many countries as Singapore, Indonesia, South Korea, Dubai, Pakistan, Sri Lanka, Vietnam, Iran, Malaysia, Mexico, Chile, Brazil, Holland, Italy, Belgium, Russia, Moldova, Paraguay, Uruguay, Germany, Spain, USA etc. More than 40 countries.; commonly we have more than 500tons stainless steel materials in stock; so w can arrange the soonest delivery too; also we hope we will have chance to cooperate with your esteemed company!

- Q: How do you prevent discoloration on stainless steel sheets?

- There are several steps you can take to prevent discoloration on stainless steel sheets. Firstly, it is essential to clean the surface regularly. Use mild soap or detergent with warm water and avoid abrasive cleaners or scrubbing pads that can cause scratches. Secondly, avoid using harsh chemicals or cleaners that contain chlorine, bleach, ammonia, or acids. Stick to mild and non-abrasive cleaners specifically made for stainless steel. After cleaning, make sure to rinse the sheet thoroughly with clean water to remove any residue from the cleaning solution. Residual chemicals can cause discoloration if left on the surface for too long. It is important to dry the stainless steel sheet completely after cleaning and rinsing. Moisture left on the surface can lead to water spots or staining, especially in areas with hard water. Use a soft cloth or towel to remove all moisture and ensure a dry and shiny surface. Applying protective coatings or sealants designed for stainless steel can help prevent discoloration. These coatings create a barrier that protects the surface from environmental factors like humidity, oxidation, and staining. Proper handling and care are also crucial. Avoid dragging or sliding objects across the sheets to prevent scratches or abrasions that may lead to discoloration. Handle the sheets with care, using clean gloves or a soft cloth to minimize the risk of surface damage. Regularly inspect the stainless steel sheets for any signs of discoloration or damage. Address any issues promptly by following the appropriate cleaning and maintenance procedures to prevent further damage and maintain the appearance of the stainless steel. By following these preventive measures, you can effectively minimize discoloration on stainless steel sheets and keep them looking clean, shiny, and free from stains for a longer period of time.

- Q: Can stainless steel sheets be used for power generation equipment?

- Stainless steel sheets are indeed applicable for power generation equipment. With its versatility, stainless steel possesses a range of advantageous qualities specifically tailored for power generation applications. Its corrosion resistance is exceptional, a paramount characteristic for equipment that comes into contact with water, steam, or other corrosive substances. Moreover, stainless steel exhibits remarkable strength and durability, enabling it to withstand the elevated temperatures and pressures frequently encountered in power generation systems. Another notable attribute is its proficiency as an electrical conductor, rendering it suitable for electrical components and connections within the equipment. Consequently, stainless steel sheets are widely employed in the construction of power generation equipment, including turbines, boilers, heat exchangers, and exhaust systems.

- Q: What are the benefits of using textured stainless steel sheets in decorative lighting fixtures?

- Using textured stainless steel sheets in decorative lighting fixtures offers several benefits. Firstly, the textured surface adds visual interest and enhances the overall aesthetic appeal of the fixture. The texture can create unique patterns and reflections, adding depth and dimension to the lighting design. Additionally, stainless steel is a durable material that is resistant to corrosion and staining, ensuring the longevity and durability of the fixture. This makes it a reliable choice for decorative lighting fixtures that are exposed to different environmental conditions. Moreover, stainless steel is easy to clean and maintain, requiring minimal effort for upkeep. Overall, the use of textured stainless steel sheets in decorative lighting fixtures combines both functional and aesthetic advantages, making it an ideal choice for designers and homeowners alike.

- Q: Are stainless steel sheets suitable for wastewater treatment plants?

- Yes, stainless steel sheets are highly suitable for wastewater treatment plants. Stainless steel is known for its corrosion resistance, durability, and ability to withstand harsh and corrosive environments, making it an ideal material for such applications. It can effectively handle the challenges posed by wastewater treatment plants, including exposure to chemicals, moisture, and high temperatures, while maintaining its structural integrity and preventing contamination.

- Q: Can stainless steel sheets be used for decorative screens?

- Yes, stainless steel sheets can be used for decorative screens. Stainless steel is a versatile material that is often used for its aesthetic appeal and durability. It can be easily shaped and formed into various designs, making it suitable for creating decorative screens. Additionally, stainless steel is resistant to corrosion and can withstand harsh weather conditions, making it ideal for both indoor and outdoor applications. With its sleek and modern appearance, stainless steel sheets can add a touch of elegance and sophistication to any space, making them a popular choice for decorative screens in residential and commercial settings.

- Q: How are stainless steel sheets manufactured?

- Stainless steel sheets are manufactured through a multi-step process that involves several key stages. The production begins with the melting of raw materials, including iron ore, chromium, and nickel, in an electric arc furnace. This process helps to eliminate impurities and create a molten metal. Once the molten metal is obtained, it is cast into slabs or billets. These slabs are then hot rolled, which involves passing them through a series of rollers to reduce their thickness and increase their length. This initial rolling process also helps in refining the grain structure of the steel, making it more uniform. After hot rolling, the steel is pickled and annealed to remove any scale or impurities formed during the initial rolling process. Pickling involves immersing the steel in a bath of acid to remove the surface oxide layer, while annealing is a heat treatment process that helps to reduce internal stresses and improve the steel's ductility. Following pickling and annealing, the steel is cold rolled. Cold rolling involves passing the annealed steel through a set of rollers at room temperature to further reduce its thickness and improve its surface finish. This process also imparts the desired mechanical properties to the stainless steel sheets. Once the desired thickness is achieved through cold rolling, the stainless steel sheets are subjected to various finishing processes. These may include surface treatments like polishing, embossing, or etching to enhance the appearance and texture of the sheets. Additionally, the sheets can be cut to size using shearing or laser cutting techniques. Finally, the stainless steel sheets undergo quality control checks to ensure they meet the required specifications. This includes inspecting the dimensions, surface finish, and mechanical properties of the sheets. Once approved, the sheets are ready for packaging and distribution to various industries that utilize stainless steel in their applications. Overall, the manufacturing process of stainless steel sheets involves a combination of melting, casting, hot rolling, pickling, annealing, cold rolling, and finishing. This meticulous process ensures the production of high-quality stainless steel sheets that possess excellent corrosion resistance, strength, and aesthetic appeal.

- Q: Are stainless steel sheets suitable for architectural handrails or guardrails?

- Yes, stainless steel sheets are highly suitable for architectural handrails or guardrails. Stainless steel is a popular choice for these applications due to its excellent strength, durability, and corrosion resistance properties. It is able to withstand various weather conditions and is resistant to rust, making it ideal for outdoor installations. Stainless steel sheets can be easily customized and fabricated into different shapes and sizes, allowing for flexibility in design. Additionally, stainless steel has an aesthetic appeal that complements modern architectural designs. It is a low-maintenance material that requires minimal upkeep, making it a cost-effective choice in the long run. Overall, stainless steel sheets are a reliable and versatile option for architectural handrails or guardrails.

- Q: Can stainless steel sheets be used for elevator ceilings or floors?

- Yes, stainless steel sheets can be used for elevator ceilings or floors. Stainless steel is a durable and resistant material, making it suitable for areas that require frequent cleaning and maintenance, such as elevator interiors. Additionally, stainless steel offers an aesthetically pleasing and modern look, enhancing the overall appearance of elevator ceilings and floors.

- Q: Are stainless steel sheets suitable for high-traffic areas?

- Yes, stainless steel sheets are suitable for high-traffic areas. Stainless steel is known for its durability, strength, and resistance to corrosion, making it an excellent choice for areas that experience heavy foot traffic. It can withstand constant use and abuse, including scratches, dents, and impact, without compromising its structural integrity. Additionally, stainless steel sheets are easy to clean and maintain, making them ideal for areas that require frequent cleaning and disinfection. Overall, stainless steel sheets are a reliable and long-lasting option for high-traffic areas.

- Q: What are the common manufacturing standards for stainless steel sheets?

- There are several common manufacturing standards for stainless steel sheets that ensure their quality and consistency. One of the most widely recognized standards is the ASTM International (formerly known as the American Society for Testing and Materials) standard. ASTM A240 is the specific standard for stainless steel sheets, which specifies the requirements for chemical composition, mechanical properties, and other relevant characteristics of the material. Another important manufacturing standard is the EN (European Norm) standard, specifically EN 10088, which provides guidelines for stainless steel flat products, including sheets. This standard covers various aspects such as dimensions, tolerances, surface finishes, and more. Additionally, there are national standards developed by different countries. For example, in Japan, the Japanese Industrial Standards (JIS) classify stainless steel sheets under various specifications such as JIS G4304 and JIS G4305. These standards define the requirements for chemical composition, mechanical properties, and surface finishes of stainless steel sheets. In the United States, the American Iron and Steel Institute (AISI) also sets standards for stainless steel sheets. The AISI 300 and 400 series are commonly used in the manufacturing of stainless steel sheets, and their properties are defined by the AISI. It is important for manufacturers and suppliers to adhere to these standards to ensure that the stainless steel sheets meet the desired quality requirements and can be used reliably in various applications. These standards help maintain consistency, compatibility, and traceability in the production and use of stainless steel sheets across different industries.

Send your message to us

Stainless Steel Sheet for Multi Fields Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords