Stainless Steel Sheet/Plate 309 with High Temperature Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet/Plate 309 with High Temperature Resistance

Description of Stainless Steel Sheet/Plate 309 with High Temperature Resistance:

304 stainless steel is the most widely used in the 300 series stainless steel. Its anti-corrosion property is stronger than the 200-series

stainless steel, but the anti-acid property is worse than 316. 304 stainless steel have a good resistance in high temperature and the

excellent corrosion resistance. 304 stainless steel is more expensive than 201, cheaper than the 316.

1. Commodity: 304 Stainless Steel

2. Technique: Cold Rolled/hot rolled Stainless Steel

3. Grade: 304 Stainless Steel

4. Type: Stainless Steel Sheet/coil

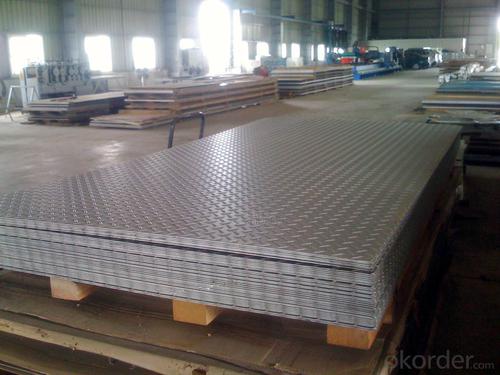

5. Finish: 2B/Ba/8K/Emboss/Etch

6. Edge: mill edge /silted edge

7.Size:1219mm*2438mm,1219mm*3048mm,or as customized

Main Features of Stainless Steel Sheet/Plate 309 with High Temperature Resistance:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Specifications of Stainless Steel Sheet/Plate 309 with High Temperature Resistance:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics Stainless Steel Sheet/Plate 309 with High Temperature Resistance:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

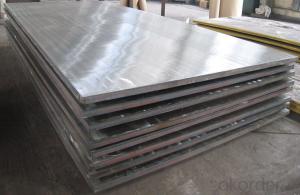

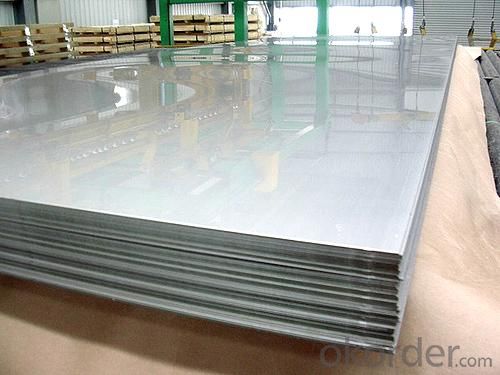

Images of Stainless Steel Sheet/Plate 309 with High Temperature Resistance:

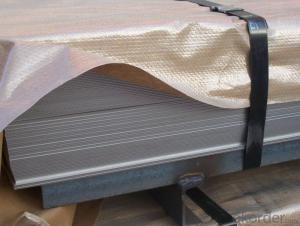

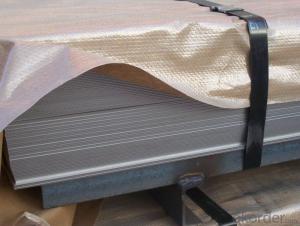

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ of Stainless Steel Sheet/Plate 309 with High Temperature Resistance:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be used for elevator floors?

- Indeed, elevator floors can indeed make use of stainless steel sheets. Known for its durability and resistance to corrosion, stainless steel is widely employed in numerous fields, including elevator interiors. Elevator floors adorned with stainless steel sheets exude a sophisticated and contemporary aesthetic, all while effectively withstanding scratches, blemishes, and impacts. Moreover, stainless steel's effortless cleanliness and maintenance make it an ideal selection for elevator floors that endure substantial foot traffic.

- Q: How thick is 10gauge in stainless steel plate?

- To understand the word "guage", is to understand the 202304201 steel, or the same number of sandpaper. Such as steel No. 304, sandpaper 360.

- Q: Do stainless steel sheets have a specific weight?

- Yes, stainless steel sheets have a specific weight. The weight of a stainless steel sheet depends on its dimensions (length, width, and thickness) as well as the specific type and grade of stainless steel used.

- Q: Can stainless steel sheets be used in industrial applications?

- Yes, stainless steel sheets can definitely be used in a wide range of industrial applications. Stainless steel is known for its excellent corrosion resistance, durability, and strength, making it ideal for various industrial environments. It is commonly used in sectors such as automotive, aerospace, construction, manufacturing, food and beverage, chemical processing, and many others. Stainless steel sheets are often used for their ability to withstand high temperatures, harsh chemicals, and extreme conditions. They can be fabricated into different shapes and sizes, making them suitable for a wide range of applications. Stainless steel sheets are commonly used for manufacturing equipment and machinery, storage tanks, pipelines, architectural structures, and as a protective layer on surfaces that require resistance to corrosion. Furthermore, stainless steel sheets offer hygienic properties, making them suitable for applications in the food and beverage industry. They are easy to clean, maintain, and sterilize, ensuring compliance with strict industry standards. In summary, stainless steel sheets are versatile and reliable materials that can be effectively used in various industrial applications due to their exceptional corrosion resistance, durability, strength, and hygienic properties.

- Q: What stainless steel can be used instead of galvanized sheet?

- Zinc plating is mainly for beauty and no rust;Stainless steel is the primary quality of stainless steel;If both really replace the 201 can be, mainly considering the price of stainless steel;Galvanized plate with stainless steel to replace my feeling is not very ideal, costs a lot, propose instead of using cold board.Galvanized steel sheet is to prevent the corrosion of steel plate surface and prolong its service life, and the surface of steel plate is coated with a layer of metal zinc. This kind of zinc coated steel plate is called galvanized sheet.

- Q: What are the applications of stainless steel sheets in the construction industry?

- Due to their unique properties and characteristics, stainless steel sheets have various applications in the construction industry. Here are some of the key uses of stainless steel sheets in construction: 1. Roofing and Cladding: Commercial and residential buildings often utilize stainless steel sheets for their roofing and cladding needs. These sheets are highly resistant to corrosion, harsh weather conditions, and fire, making them a durable and long-lasting option. 2. Facades and Curtain Walls: Stainless steel sheets are commonly employed in the construction of facades and curtain walls. Their appealing appearance, high strength, and resistance to staining and fading make them a popular choice for creating visually attractive and low-maintenance building exteriors. 3. Structural Components: Stainless steel sheets are utilized in the construction of structural components such as beams, columns, and support systems. The sheets' high strength-to-weight ratio, ability to resist deformation, and durability make them ideal for maintaining the structural integrity of buildings. 4. Handrails and Balustrades: Both indoor and outdoor settings often feature stainless steel sheets for designing handrails, balustrades, and guardrails. These sheets offer excellent resistance to corrosion, impact, and wear, while their sleek and modern appearance adds an aesthetic touch to the overall design. 5. Kitchen and Bathroom Fixtures: Stainless steel sheets are extensively used for fabricating kitchen and bathroom fixtures like sinks, countertops, backsplashes, and shower enclosures. Their ability to resist moisture, heat, and stains, along with their easy maintenance, make them a practical and hygienic choice. 6. Interior Design Elements: Various interior design elements, including wall panels, ceiling panels, elevator interiors, and decorative screens, utilize stainless steel sheets in their construction. The sheets' smooth and reflective surface, combined with their versatility in terms of finishes and patterns, allows for creating visually appealing and modern interiors. 7. HVAC Systems: HVAC systems often incorporate stainless steel sheets due to their high-temperature resistance, corrosion resistance, and ease of cleaning. These sheets are commonly used in ductwork, air handling units, and exhaust systems to ensure efficient and durable performance. In summary, stainless steel sheets offer numerous advantages in the construction industry, including durability, corrosion resistance, low maintenance requirements, and aesthetic appeal. These qualities make them a preferred choice for a wide range of applications, contributing to the overall quality and longevity of construction projects.

- Q: Can stainless steel sheets be used for wall paneling?

- Yes, stainless steel sheets can be used for wall paneling. Stainless steel is a versatile material that is known for its durability, resistance to corrosion, and aesthetic appeal. It is commonly used in various applications, including wall paneling in both residential and commercial settings. Stainless steel sheets can be easily installed as wall panels, providing a modern and sleek look to the space. Additionally, stainless steel is easy to clean and maintain, making it a practical choice for wall paneling in areas that require regular cleaning, such as kitchens and bathrooms. Overall, stainless steel sheets are a great option for wall paneling due to their durability, aesthetic appeal, and ease of maintenance.

- Q: Is Baoding mirror stainless steel plate mirror on both sides?

- Yes, mirror stainless steel plate is divided into: single universal grinding 8K stainless steel plate, stainless steel plate, 8K universal grinding double-sided single-sided grinding 8K stainless steel plate, double-sided grinding of 8K stainless steel plate, manufacturers generally can be customized according to your requirements, the price is not the same.

- Q: What is the water absorption rate of stainless steel sheets?

- The water absorption rate of stainless steel sheets is typically very low or negligible. Stainless steel is known for its excellent corrosion resistance and impermeability to liquids, including water. Due to its unique composition and surface properties, stainless steel sheets do not readily absorb water or allow it to penetrate the material. This makes stainless steel a preferred choice for various applications where resistance to moisture is crucial, such as in the food and beverage industry, medical equipment, and outdoor structures.

- Q: How do stainless steel sheets compare to other materials, such as aluminum or carbon steel?

- Stainless steel sheets possess several advantages when compared to materials like aluminum or carbon steel. Their corrosion resistance stands as one of the main benefits. By containing chromium, stainless steel forms a passive film on its surface, guarding it against rust and other forms of corrosion. As a result, stainless steel sheets prove ideal for outdoor and marine applications, where exposure to moisture and corrosive elements is common. In terms of strength, stainless steel sheets generally surpass aluminum but fall short of carbon steel. Nevertheless, through heat treatment, stainless steel sheets can be hardened, increasing their strength and durability. This characteristic renders them suitable for applications that demand high strength and resistance to wear and tear. Stainless steel sheets also exhibit remarkable heat resistance. They can withstand high temperatures without compromising their structural integrity, making them appropriate for use in industries such as food processing, chemicals, and petrochemicals. Another advantage of stainless steel sheets lies in their aesthetic appeal. With their sleek and modern appearance, they complement various design styles. Architects and interior designers frequently include stainless steel sheets in their projects, particularly when visual appeal holds significance. However, despite the numerous advantages, it is important to consider certain factors when working with stainless steel sheets. Stainless steel can be more expensive than aluminum or carbon steel, particularly for high-grade alloys. Additionally, its higher strength and hardness may pose challenges during shaping and machining. Specialized tools and techniques may be necessary when working with stainless steel sheets. In conclusion, stainless steel sheets offer a unique combination of corrosion resistance, strength, heat resistance, and aesthetic appeal. Depending on the specific requirements of a project, stainless steel may be the preferred choice over materials like aluminum or carbon steel.

Send your message to us

Stainless Steel Sheet/Plate 309 with High Temperature Resistance

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords