Stainless Steel Sheet/Plate 304 with Low Pricing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet/Plate 304 with Low Pricing

Description of Stainless Steel Sheet/Plate 304 with Low Pricing:

304 stainless steel is the most widely used in the 300 series stainless steel. Its anti-corrosion property is stronger than the 200-series

stainless steel, but the anti-acid property is worse than 316. 304 stainless steel have a good resistance in high temperature and the

excellent corrosion resistance. 304 stainless steel is more expensive than 201, cheaper than the 316.

1. Commodity: 304 Stainless Steel

2. Technique: Cold Rolled/hot rolled Stainless Steel

3. Grade: 304 Stainless Steel

4. Type: Stainless Steel Sheet/coil

5. Finish: 2B/Ba/8K/Emboss/Etch

6. Edge: mill edge /silted edge

7.Size:1219mm*2438mm,1219mm*3048mm,or as customized

Main Features of Stainless Steel Sheet/Plate 304 with Low Pricing:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Specifications of Stainless Steel Sheet/Plate 304 with Low Pricing:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics Stainless Steel Sheet/Plate 304 with Low Pricing:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

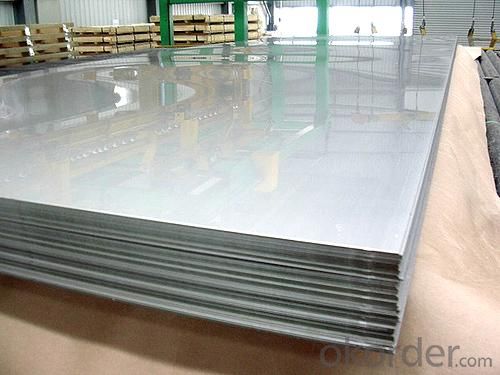

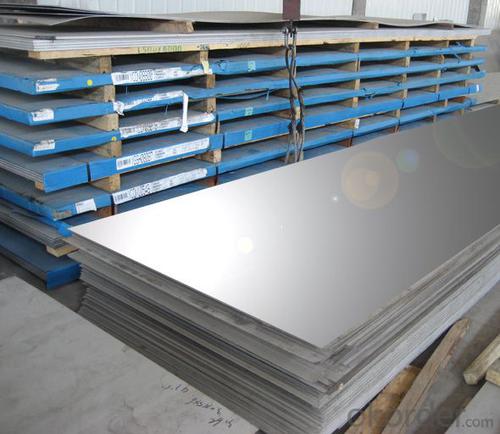

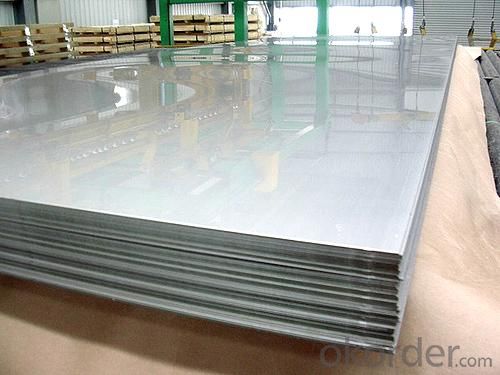

Images of Stainless Steel Sheet/Plate 304 with Low Pricing:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ of Stainless Steel Sheet/Plate 304 with Low Pricing:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be used for automotive applications?

- Yes, stainless steel sheets can be used for automotive applications. Stainless steel is a highly versatile and durable material that offers excellent resistance to corrosion, heat, and impact. These properties make it ideal for automotive applications where durability and resistance to harsh environments are essential. Stainless steel sheets can be used in various parts of the automotive industry, including body panels, exhaust systems, fuel tanks, and even interior components. Additionally, stainless steel can be easily formed, welded, and manipulated to meet specific design requirements, making it a popular choice in the automotive industry.

- Q: Are stainless steel sheets suitable for architectural applications?

- Yes, stainless steel sheets are highly suitable for architectural applications. They possess a sleek and modern appearance, excellent corrosion resistance, durability, and can withstand various environmental conditions. Additionally, stainless steel sheets offer versatility in terms of design possibilities and can be easily fabricated and installed, making them a popular choice in architectural projects.

- Q: Are stainless steel sheets fire-resistant?

- Stainless steel sheets possess fire resistance, indeed. They are composed of a heat-resistant material, stainless steel, which can endure elevated temperatures without compromising its structural integrity. This renders it a perfect option for situations demanding fire resistance, like in the construction sector, where stainless steel sheets are frequently employed to fireproof walls, roofs, and enclosures. Moreover, stainless steel boasts a remarkable melting point, allowing it to endure intense heat without distortion or melting, thereby amplifying its fire-resistant characteristics.

- Q: Can stainless steel sheets be used as a backsplash in kitchens?

- Yes, stainless steel sheets can be used as a backsplash in kitchens. Stainless steel is a popular choice for kitchen backsplashes due to its durability, heat resistance, and easy maintenance. It is resistant to stains, water, and rust, making it ideal for an area that is prone to spills and splatters. Additionally, stainless steel sheets can be easily cleaned with soap and water or stainless steel cleaner, ensuring a hygienic and sanitary environment in the kitchen. The sleek and modern look of stainless steel also adds a contemporary touch to any kitchen decor. Overall, stainless steel sheets are a practical and stylish choice for a kitchen backsplash.

- Q: What's the difference between 304 stainless steel and 301 stainless steel?

- 304 stainless steel is one kind of universal, which is widely used to produce good performance (corrosion resistance and formability) equipment and parts; 301 stainless steel showed obvious hardening during deformation, is used for various occasions with high intensity.

- Q: How do I prevent intergranular corrosion on stainless steel sheets?

- To prevent intergranular corrosion on stainless steel sheets, there are several steps that can be taken: 1. Opt for the appropriate stainless steel grade: Choose stainless steel grades that are specifically designed to resist intergranular corrosion, such as 304L, 316L, or 321. These grades have a lower carbon content, which minimizes the formation of chromium carbides at grain boundaries. 2. Apply heat treatment: After fabrication or welding, subject the stainless steel sheets to a solution annealing or post-weld heat treatment process. This treatment eliminates any chromium carbides that may have formed during welding or high-temperature processing, effectively preventing intergranular corrosion. 3. Avoid high temperature exposure: It is crucial to avoid subjecting stainless steel sheets to temperatures between 450 to 850 degrees Celsius (842 to 1562 degrees Fahrenheit) for extended periods. Prolonged exposure to such temperatures can lead to the formation of chromium carbides at the grain boundaries, rendering the stainless steel susceptible to intergranular corrosion. 4. Utilize proper welding techniques: When welding stainless steel sheets, it is important to employ low heat input and minimize the duration of exposure to high temperatures. These measures help reduce the formation of chromium carbides and preserve the corrosion resistance of the stainless steel. 5. Employ pickling and passivation: After fabrication or welding, ensure that the stainless steel sheets undergo thorough pickling and passivation. Pickling removes any surface contaminants, while passivation forms a protective oxide layer that prevents intergranular corrosion. 6. Regularly maintain and clean: To prevent potential corrosion, it is essential to keep the stainless steel sheets clean and free from contaminants. Regularly clean the surfaces using mild detergents and avoid the use of harsh chemicals or abrasive materials that may damage the protective oxide layer. By following these preventative measures, the risk of intergranular corrosion on stainless steel sheets can be significantly reduced, allowing for the preservation of their corrosion resistance properties and an extended lifespan.

- Q: Can stainless steel sheets be used in food processing or medical applications?

- Stainless steel sheets have the capability to be utilized in food processing and medical applications. The reason behind its popularity in these industries is its outstanding resistance to corrosion, high durability, and effortless cleaning properties. The material is able to withstand chemical reactions, ensuring safety when it comes into contact with food and medical equipment. Commonly employed in food processing equipment, storage tanks, countertops, and surgical instruments, stainless steel sheets conform to the strict hygiene standards mandated in the food and medical sectors, thus establishing themselves as a dependable and fitting material for these applications.

- Q: What are the advantages of using stainless steel sheets?

- There are several advantages to using stainless steel sheets in various applications. Firstly, stainless steel is known for its exceptional corrosion resistance. It is highly resistant to rust and stains, making it a suitable choice for environments where moisture and other corrosive substances are present. This durability ensures that stainless steel sheets maintain their aesthetic appeal and structural integrity over time. Secondly, stainless steel is incredibly strong and durable. It has a high tensile strength, meaning it can withstand heavy loads and resist deformation. This makes stainless steel sheets ideal for applications that require robustness, such as construction, automotive, and industrial projects. Thirdly, stainless steel is hygienic and easy to clean. It has a non-porous surface that prevents the growth of bacteria and other microorganisms, making it a popular choice for food processing equipment, medical tools, and healthcare facilities. Additionally, stainless steel sheets are easy to maintain, as they can be wiped clean or sterilized without damaging the material. Moreover, stainless steel sheets are aesthetically pleasing and versatile. They have a sleek and modern appearance that can enhance the visual appeal of architectural designs, interior decorations, and kitchen appliances. Stainless steel sheets come in a variety of finishes, such as brushed, mirror, or textured, allowing for customization to suit specific design preferences. Lastly, stainless steel is an environmentally friendly material. It is 100% recyclable, which means it can be reused and repurposed without any loss in quality or performance. This makes stainless steel sheets a sustainable choice, reducing the need for new raw materials and minimizing waste. In conclusion, the advantages of using stainless steel sheets include excellent corrosion resistance, strength and durability, hygienic properties, aesthetic appeal, and environmental sustainability. These characteristics make stainless steel sheets a versatile and reliable choice for a wide range of applications.

- Q: Can stainless steel sheets be used for wall paneling?

- Yes, stainless steel sheets can be used for wall paneling. Stainless steel is a versatile material that is known for its durability, resistance to corrosion, and aesthetic appeal. It is commonly used in various applications, including wall paneling in both residential and commercial settings. Stainless steel sheets can be easily installed as wall panels, providing a modern and sleek look to the space. Additionally, stainless steel is easy to clean and maintain, making it a practical choice for wall paneling in areas that require regular cleaning, such as kitchens and bathrooms. Overall, stainless steel sheets are a great option for wall paneling due to their durability, aesthetic appeal, and ease of maintenance.

- Q: What's the difference between stainless steel 304 and stainless steel 202?

- Is the steel of the oxide layer was removed, put a drop of water, rub rub after copper sulfate, such as discoloration, usually stainless steel; such as purple red: nonmagnetic as high manganese steel, magnetic for ordinary steel or low-alloy steel.

Send your message to us

Stainless Steel Sheet/Plate 304 with Low Pricing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords