LZCORRIGATED SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CORRIGATED SHEET 7210701000

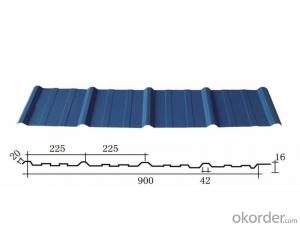

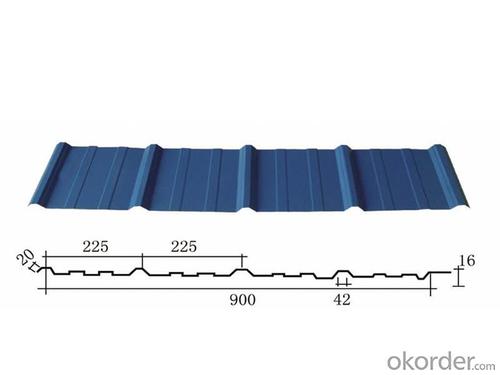

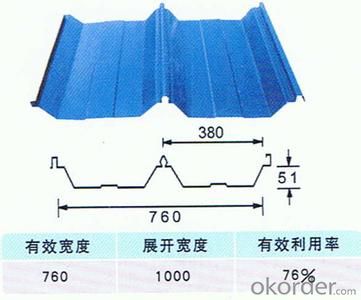

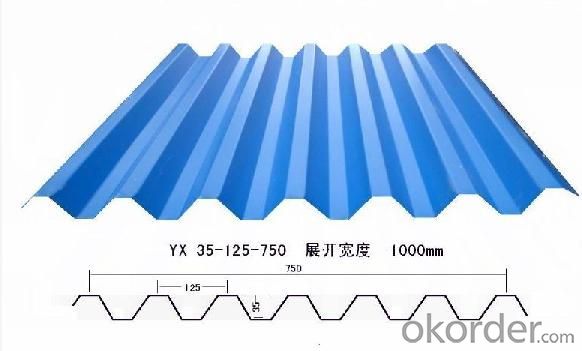

Product Name:corrugated steel roofing sheet

Effective Width:650mm to 1250mm

Thickness:0.13mm-0.8mm

Material PPGI/PPGL steel coil

Coating:Z30-Z275,AZ30-AZ180

Color:white,blue or any RAL colors

length:1m-11.8m according to the container

top color coating:12um-25um

Back color coating:7um-10um

HRB:50-95

Base plate:PRE-PAINTED ALUZINC STEEL COIL,PRE-PAINTED GALVANIZED STEEL COIL

In continuous units in cold rolled steel strip, galvanized steel (electro galvanized and hot dip galvanized) as substrate, after surface pretreatment (degreasing and science processing), using the method of roll coating, coated with a layer or multi-layer liquid coating of plate, after baking and cooling income is the coating steel plate. Because the coating can have a variety of colors, on the habits of the coated steel sheet is called color coating steel plate. Because the coating is carried out before the sheet metal forming, in foreign countries which is called pre coating plate.

Color coated steel sheet is an organic coating coating on the steel surface, it has the advantages of beautiful appearance, bright color, high strength, good corrosion resistance, easy processing molding, but also allows the user to reduce costs, reduce pollution.

From the United States in 1935 to establish the first continuously coated steel line to begin, color coated steel plate has been widely applied, the current color coated plate varieties, about more than 600 kinds, the advantages of color coated sheet and organic polymer and steel plate of the two, which has good colorability, organic polymer molding, corrosion resistance and decorative, and steel plate with high strength and easy processing, can easily be punching cutting, bending, deep drawing processing. Made this makes organic coated steel sheet products have excellent practical, decorative, workability, durability.

- Q: What are the insulation properties of steel sheets?

- Steel sheets have limited insulation properties as they are strong conductors of heat and electricity. However, their high thermal mass allows them to absorb and slowly release heat, which can provide some degree of insulation. To enhance insulation, steel sheets can be combined with other insulating materials or used in conjunction with insulation systems.

- Q: What is the tensile strength of steel sheets?

- The tensile strength of steel sheets typically ranges from 370 to 690 megapascals (MPa), depending on the grade and thickness of the steel.

- Q: How do you repair damaged steel sheets?

- To repair damaged steel sheets, the first step is to clean the area thoroughly, removing any dirt, rust, or debris. Then, using a grinder or sandpaper, smooth out the damaged area until the surface is even. Next, apply a suitable metal primer to the repaired area and let it dry. Finally, use a steel filler or epoxy putty to fill in any remaining gaps or imperfections. Once the filler is dry, sand it down to ensure a smooth finish, and paint the repaired area to match the surrounding steel sheets.

- Q: What is the maximum load-bearing capacity of steel sheets?

- The maximum load-bearing capacity of steel sheets can vary depending on the specific type and thickness of the steel sheet. Generally, steel sheets are known for their high strength and durability, allowing them to support heavy loads. The load-bearing capacity of steel sheets is typically measured in terms of its yield strength or ultimate tensile strength. Yield strength refers to the maximum amount of stress that a steel sheet can withstand before it begins to deform permanently, while ultimate tensile strength refers to the maximum stress it can handle before fracturing. The load-bearing capacity of steel sheets can range from a few hundred pounds to several thousand pounds per square inch (psi). For example, mild steel sheets typically have a yield strength of around 50,000 psi, allowing them to support moderate loads. High-strength steel sheets, on the other hand, can have a yield strength of over 100,000 psi, enabling them to withstand heavy loads. It's important to note that the load-bearing capacity of steel sheets can also be influenced by factors such as the sheet's dimensions, surface condition, and the method of support. Additionally, engineers and structural designers often consider safety margins and factor of safety when determining the maximum load-bearing capacity of steel sheets in specific applications. Therefore, it is recommended to consult relevant engineering standards, specifications, or professionals for accurate load-bearing capacity information in a particular context.

- Q: What is the average thermal conductivity of steel sheets?

- The average thermal conductivity of steel sheets can vary depending on various factors such as the specific type or grade of steel, its composition, and temperature. However, on average, the thermal conductivity of steel sheets ranges between 15 and 30 Watts per meter-kelvin (W/m·K). This means that steel sheets are relatively good conductors of heat, allowing them to efficiently transfer thermal energy across their surfaces. It is important to note that the actual thermal conductivity of a specific steel sheet can be determined through laboratory testing or by consulting technical specifications provided by the manufacturer.

- Q: How are steel sheets protected during storage in outdoor environments?

- Steel sheets in outdoor environments are often protected through various measures. One effective technique involves applying a protective coating onto the surface of the sheets. This coating serves as a barrier, preventing direct contact between the steel and moisture or other environmental factors. It can take the form of paint, varnish, or a specialized substance that resists corrosion. Additionally, to provide an extra layer of protection, steel sheets can be covered with plastic wrap or a tarpaulin. This shields them from rain, snow, and other weather conditions that could potentially lead to rust or corrosion. Moreover, proper stacking and storage techniques play a crucial role in safeguarding steel sheets. It is important to store them in a dry and well-ventilated area, preferably on pallets or racks to keep them off the ground. Ample space between the stacks allows for air circulation, minimizing the risk of moisture accumulation. Regular maintenance and inspection are vital to ensure continuous protection of steel sheets in outdoor storage. The protective coating should be periodically examined for any signs of damage or wear, and any necessary touch-ups or reapplications should be promptly carried out. By implementing these protective measures, steel sheets can be shielded from the harsh elements commonly found in outdoor environments. This guarantees their longevity and preserves their quality.

- Q: How do steel sheets compare to other sheet materials like aluminum or stainless steel?

- Steel sheets have several advantages over other sheet materials like aluminum or stainless steel. Firstly, steel sheets are known for their exceptional strength and durability. They can withstand heavy loads and are resistant to impact, making them ideal for applications that require high strength and stability. Aluminum sheets, on the other hand, are relatively softer and less resistant to impacts, making them more suitable for lightweight applications. Secondly, steel sheets offer excellent corrosion resistance. While stainless steel sheets also possess this characteristic, steel sheets can be coated with protective layers or galvanized to enhance their corrosion resistance even further. This makes steel sheets more suitable for outdoor applications or environments with high humidity or exposure to harsh chemicals. Aluminum sheets, on the contrary, are prone to corrosion and typically require additional coating or treatment for protection. Moreover, steel sheets are more cost-effective compared to aluminum or stainless steel sheets. Steel is widely available and has a lower production cost, making steel sheets a more affordable option for many industries. Aluminum sheets, on the other hand, tend to be more expensive due to the higher cost of the raw material and the manufacturing process involved. Stainless steel sheets are also relatively expensive due to the additional alloying elements present in their composition. Lastly, steel sheets offer excellent fire resistance. They have a high melting point and do not easily catch fire or contribute to the spread of flames. This makes steel sheets the preferred choice for applications that require fire safety, such as construction or transportation. In summary, steel sheets stand out due to their exceptional strength, durability, corrosion resistance, cost-effectiveness, and fire resistance. While aluminum and stainless steel sheets have their own unique properties and applications, steel sheets are often favored for their superior overall performance in various industries.

- Q: How do steel sheets perform in electrical resistance?

- Steel sheets have high electrical resistance, meaning they are not good conductors of electricity.

- Q: How thick are steel sheets available?

- A wide variety of thicknesses can be found for steel sheets, catering to the specific needs of each application. Steel sheets commonly come in thicknesses ranging from 0.5mm (or 0.020 inches) up to several inches. Gauge is typically used to measure the thickness of steel sheets, with lower gauge numbers indicating thicker sheets. Nevertheless, it's worth mentioning that the availability of steel sheets in particular thicknesses might differ depending on the supplier and the type of steel employed.

- Q: Can steel sheets be used for architectural facades?

- Yes, steel sheets can be used for architectural facades. Steel is a versatile material that offers strength, durability, and a sleek aesthetic, making it suitable for various architectural applications including facades. Steel sheets can be customized, shaped, and finished to create unique and visually appealing facades for buildings.

Send your message to us

LZCORRIGATED SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords