Stainless steel plate/sheet 304,201,202,310S,316L,316Ti,304L,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

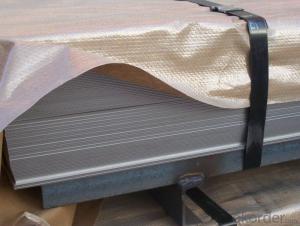

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: Are stainless steel sheets suitable for elevator handrails?

- Yes, stainless steel sheets are suitable for elevator handrails. Stainless steel is a popular choice for handrails in elevators due to its durability, corrosion resistance, and aesthetic appeal. Elevator handrails are subject to constant use and exposure to various environmental factors, such as moisture and fingerprints. Stainless steel is highly resistant to corrosion, ensuring the longevity and maintenance-free operation of the handrails. Additionally, stainless steel has a sleek and modern appearance that complements the overall design of elevators. Its smooth surface is easy to clean and maintain, making it a hygienic choice for handrails in public spaces. Overall, stainless steel sheets are an excellent material choice for elevator handrails.

- Q: Can stainless steel sheets be used in architectural applications?

- Architectural applications can indeed utilize stainless steel sheets. Stainless steel possesses immense versatility and boasts exceptional strength, durability, and resistance against corrosion, thus rendering it suitable for a vast array of architectural endeavors. It finds common application in cladding, roofing, and facade projects, while also serving as a building's structural backbone in the form of columns and beams. The malleability of stainless steel sheets allows architects to fashion them into diverse shapes and sizes, enabling the realization of unique designs and visually captivating structures. Additionally, stainless steel's sleek and contemporary appearance contributes to its allure in modern architecture. In summary, stainless steel sheets remain a favored choice in architectural applications due to their practicality, resilience, and aesthetic attributes.

- Q: Are stainless steel sheets suitable for cryogenic applications?

- Yes, stainless steel sheets are suitable for cryogenic applications due to their excellent mechanical properties, low thermal conductivity, and resistance to temperature extremes. Stainless steel can maintain its strength and integrity even at extremely low temperatures, making it an ideal material for cryogenic storage tanks, pipelines, and equipment.

- Q: How do you polish stainless steel sheets?

- Achieving a polished look for stainless steel sheets can be accomplished by following a few straightforward steps. Begin by ensuring that the surface is immaculate and devoid of any dirt or debris. To eliminate any stains or marks, a mild detergent or stainless steel cleaner can be used. Next, utilize a soft cloth or sponge to apply either a stainless steel polish or a mixture of vinegar and olive oil. Apply the polish in the direction of the grain, which typically appears as a linear pattern on the stainless steel surface. Once the polish has been applied, utilize another clean cloth to buff the surface in the same direction as the grain. Apply gentle pressure and continue buffing until the stainless steel sheets start to exhibit a shining, polished appearance. If necessary, repeat the process in areas that require further polishing, ensuring that all excess polish is wiped away to prevent streaks or residue. It is crucial to consider that different stainless steel finishes may necessitate specific polishing techniques or products. For optimal results, always consult the manufacturer's instructions or guidelines.

- Q: Can stainless steel sheets be used in medical equipment?

- Yes, stainless steel sheets can be used in medical equipment. Stainless steel is a popular choice for medical devices and equipment due to its excellent properties such as corrosion resistance, durability, and ease of cleaning. It is commonly used in surgical instruments, implants, hospital equipment, and laboratory tools. Stainless steel sheets are often used in the fabrication of medical equipment due to their versatility and ability to be molded into various shapes and sizes. Additionally, stainless steel is highly biocompatible, meaning it does not react with bodily tissues and is safe for use in medical applications. Overall, stainless steel sheets are a reliable and widely accepted material for medical equipment due to their hygienic properties and long-lasting performance.

- Q: What is the minimum thickness available for stainless steel sheets?

- The minimum thickness of stainless steel sheets can differ depending on the grade and manufacturer. Nevertheless, typically stainless steel sheets are readily obtainable in thicknesses that span from 0.4mm to 6mm. Certain manufacturers might even offer thinner sheets, like 0.3mm, for particular applications. To ascertain the precise minimum thickness that suits your specific needs, it is crucial to consult with the supplier or manufacturer.

- Q: What is the maximum thickness available for stainless steel sheets?

- The specific grade of stainless steel and the manufacturing capabilities of the supplier can cause the maximum thickness of stainless steel sheets to differ. Nevertheless, stainless steel sheets are commonly available in thicknesses ranging from 0.5mm to 80mm. It should be emphasized that thicker sheets are typically utilized for specialized purposes that demand heightened strength and durability, like construction projects or heavy machinery. To ensure the desired thickness is obtainable, it is essential to carefully consider the intended use of the stainless steel sheets and seek advice from a reputable supplier.

- Q: Can stainless steel sheets be used for elevator wall panels?

- Yes, stainless steel sheets can be used for elevator wall panels. Stainless steel is a popular choice for elevator interiors due to its durability, cleanliness, and aesthetic appeal. It offers a sleek and modern look that can enhance the overall appearance of the elevator. Moreover, stainless steel is resistant to corrosion, stains, and scratches, making it suitable for high-traffic areas like elevators. It is also easy to clean and maintain, ensuring that the elevator walls remain in good condition for a long time. Additionally, stainless steel sheets can be customized in various finishes, patterns, and colors to match the design requirements and preferences of the building or elevator. Overall, stainless steel sheets are an excellent choice for elevator wall panels.

- Q: What are the different types of stainless steel sheet edge treatments available?

- Various edge treatments are available for stainless steel sheets, each offering distinct advantages and aesthetic options. 1. The mill edge treatment is the most commonly used, where the stainless steel sheet is produced with an unfinished, straight edge. It is cost-effective and suitable for applications that prioritize functionality over appearance. 2. The slit edge treatment involves cutting the stainless steel sheet to the desired width, resulting in a smooth edge. Slit edge sheets are commonly used in industries like food processing and pharmaceuticals, where a clean, burr-free finish is necessary. 3. The deburred edge treatment focuses on removing any burrs or sharp edges from the stainless steel sheet, leaving a smooth and safe edge. It is often employed in architectural or automotive applications where safety is a concern. 4. The rolled edge treatment involves bending the stainless steel sheet to create a rounded edge. This treatment is popular in applications where safety and aesthetics are important, such as kitchen appliances or decorative pieces. 5. The beveled edge treatment refers to cutting the stainless steel sheet at an angle, creating a diagonal edge. Beveled edges are commonly used in architectural applications to achieve a smooth transition between different materials or enhance the overall design. These examples illustrate the range of stainless steel sheet edge treatments available. The choice of treatment depends on specific application requirements, including functionality, safety, and aesthetics.

- Q: Can stainless steel sheets be polished?

- Yes, stainless steel sheets can be polished. Polishing stainless steel sheets helps in removing scratches, stains, and improving the overall appearance of the metal surface.

Send your message to us

Stainless steel plate/sheet 304,201,202,310S,316L,316Ti,304L,420,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords