Stainless steel plate/sheet 304,201,202,310S,309S,316L,316Ti,321,304L,410,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

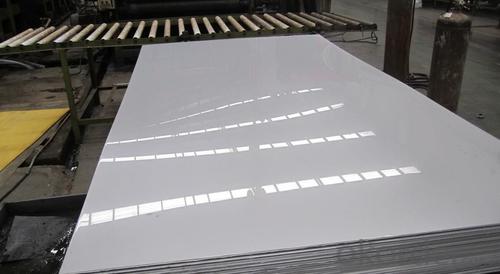

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: What are the different types of stainless steel sheet edges?

- There are three main types of stainless steel sheet edges: mill edge, slit edge, and deburred edge. 1. Mill Edge: This is the most common type of stainless steel sheet edge. It is produced during the manufacturing process and is characterized by a rough, unfinished edge. The mill edge is typically straight and perpendicular to the surface of the sheet. It is suitable for most applications where a smooth edge is not required. 2. Slit Edge: Slit edge stainless steel sheets are created by cutting large rolls of stainless steel into narrower widths. The edges of these sheets are smoother and more precise compared to the mill edge. Slit edge sheets are commonly used in applications where a more polished and precise edge is needed, such as in architectural finishes or fabrication processes. 3. Deburred Edge: A deburred edge is achieved by removing any sharp or rough edges from the stainless steel sheet. This is done to enhance safety and prevent injury during handling or installation. Deburring can be done through various methods, such as grinding, sanding, or using specialized tools. The resulting edge is smooth and free from any burrs or sharp protrusions. It is important to note that the choice of edge type depends on the specific application and requirements of the stainless steel sheet. Each edge type has its own advantages and limitations, and it is crucial to consider factors such as aesthetics, functionality, and safety when selecting the appropriate edge for a particular project.

- Q: Can stainless steel sheets be customized in terms of size and shape?

- Yes, stainless steel sheets can be customized in terms of size and shape. Stainless steel is a highly versatile material that can be easily manipulated and transformed to meet specific requirements. Whether it is a large sheet or a small one, stainless steel can be cut, shaped, and resized to fit the desired dimensions. This customization process can be achieved through various techniques such as cutting, bending, welding, and forming. Additionally, stainless steel sheets can also be perforated or embossed to add further customization and enhance their aesthetic appeal. Overall, stainless steel sheets offer great flexibility in terms of size and shape customization, making them suitable for a wide range of applications in industries such as construction, automotive, aerospace, and more.

- Q: Can stainless steel sheets be used for water purification systems?

- Yes, stainless steel sheets can be used for water purification systems. Stainless steel is highly corrosion resistant and does not react with water, making it suitable for use in water purification systems where contact with water is constant. It also has excellent mechanical properties and can withstand high pressures, making it a durable and reliable material choice in such applications.

- Q: What stainless steel can be used instead of galvanized sheet?

- Galvanized sheet can be replaced by 201 stainless steel.

- Q: Can stainless steel sheets be used in food processing industry?

- Indeed, the food processing industry can utilize stainless steel sheets. This industry favors stainless steel due to its corrosion resistance, ease of cleaning, and non-reactivity with food and beverages. Moreover, its strength and durability render it appropriate for a range of purposes such as food preparation surfaces, storage containers, and equipment. Furthermore, stainless steel sheets possess a smooth and non-porous surface, effectively impeding bacterial growth and ensuring food safety. In summary, stainless steel sheets prove to be a dependable and hygienic option for implementation in the food processing industry.

- Q: Can stainless steel sheets be used for storage tanks?

- Indeed, storage tanks can absolutely utilize stainless steel sheets. Stainless steel possesses a remarkable level of resistance to corrosion, rendering it an excellent material for the storage of a wide range of substances, such as chemicals, liquids, and gases. Its exceptional durability guarantees an extended lifespan for the storage tank, thereby minimizing the likelihood of leaks or contamination. Moreover, stainless steel tanks are effortless to clean and maintain, making them particularly suitable for industries like food and beverage, pharmaceuticals, and wastewater treatment. Furthermore, stainless steel is non-reactive, meaning it does not react with the stored substances, thus ensuring the integrity and quality of the materials being stored. All in all, stainless steel sheets serve as a dependable and versatile option for storage tank applications.

- Q: What are the different types of finishes available for stainless steel sheets?

- Stainless steel sheets come in various finishes, each with its own distinct appearance and level of protection. Some commonly used finishes include: 1. No. 1 Finish: This finish is achieved by hot rolling the stainless steel sheet, resulting in a dull and rough surface that lacks reflection. It is commonly utilized in industrial settings where appearance is not the primary concern. 2. No. 2B Finish: By cold rolling the stainless steel sheet and subsequently annealing it in a controlled atmosphere, a smooth and reflective surface is obtained. This finish is widely favored in applications that require an aesthetically pleasing appearance, such as kitchen appliances and decorative trim. 3. No. 4 Finish: Also known as brushed or satin finish, this technique involves applying a series of abrasive grits to the surface of the stainless steel sheet. It creates a uniform, linear grain pattern that is often used for architectural and decorative purposes. 4. No. 8 Finish: This highly reflective finish is achieved by polishing the stainless steel sheet to a mirror-like appearance. It is commonly employed in applications that demand a sleek and sophisticated look, such as high-end architectural projects and automotive trim. 5. BA (Bright Annealed) Finish: This finish is accomplished by annealing the stainless steel sheet in a controlled atmosphere, followed by pickling or blasting to remove any oxide scale. It results in a smooth and bright surface, making it suitable for applications that require optimum corrosion resistance, such as medical equipment and pharmaceutical processing. 6. Hairline Finish: By mechanically brushing the surface of the stainless steel sheet with fine abrasive belts, a subtle and textured look is achieved. This finish can be utilized for architectural and decorative purposes. 7. Embossed Finish: This finish entails imprinting a raised or recessed pattern onto the surface of the stainless steel sheet using a rolling mill or press. It adds texture and visual interest to the sheet and is commonly employed in applications like elevator interiors, wall cladding, and signage. These are just a few examples of the numerous finishes available for stainless steel sheets, each offering its own unique aesthetic and functional properties. The selection of the appropriate finish depends on the specific application and desired appearance.

- Q: Can stainless steel sheets be used for elevator doors?

- Elevator doors can indeed utilize stainless steel sheets. The use of stainless steel for elevator doors is quite prevalent due to its impressive attributes: its robustness, resistance to corrosion, and visually appealing nature. Stainless steel is able to withstand the daily wear and tear associated with elevator usage, remaining unscathed by scratches, dents, and stains. Moreover, stainless steel grants a sleek and contemporary appearance, rendering it a suitable material for elevator doors in various settings like commercial edifices, residential complexes, and hotels. Furthermore, stainless steel sheets can be tailored to fulfill specific design requisites, enabling a wide array of finishes, textures, and patterns to be employed, elevating the overall aesthetic of the elevator doors.

- Q: What is the electrical conductivity of stainless steel sheets?

- The electrical conductivity of stainless steel sheets is relatively low compared to other metals, such as copper or aluminum.

- Q: What is the tensile modulus of stainless steel sheets?

- The grade and specific composition of stainless steel sheets determine the variation in their tensile modulus. Nevertheless, stainless steel is widely recognized for its remarkable mechanical properties and high tensile strength. Typically, the tensile modulus of stainless steel sheets falls within the range of 180 to 200 GPa (Gigapascals), surpassing the majority of commonly utilized engineering and construction materials. This exceptional tensile modulus renders stainless steel sheets perfect for applications demanding robustness, longevity, and resistance against corrosion.

Send your message to us

Stainless steel plate/sheet 304,201,202,310S,309S,316L,316Ti,321,304L,410,430,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords