Stainless steel plate and sheet 304/304L,201,202,310S,316L,316Ti,410,420,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

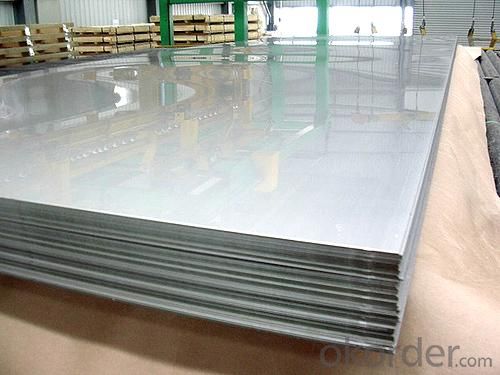

Stainless steel plate/sheet

304,201,202,310S,309S,316L,316Ti,321,304L,410,420,430,444,443,409L,904L

| Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

| Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

| Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

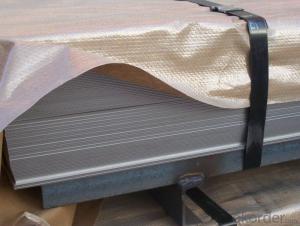

| Packaging | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

| Quality | No.1 |

| Productivity | 1200ton/day |

| Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K |

Product Shows :

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Packaging and Loading

- Q: Can stainless steel sheets be bent or formed into different shapes?

- Yes, stainless steel sheets can be bent or formed into different shapes. Stainless steel is a highly versatile material that can be manipulated through various processes such as bending, rolling, and forming to create a wide range of shapes and structures. The ability to bend stainless steel sheets makes it suitable for applications in industries such as architecture, automotive, and manufacturing. Additionally, stainless steel's corrosion resistance properties are not compromised during the bending process, making it a durable and long-lasting material choice for various purposes.

- Q: Are stainless steel sheets suitable for architectural louvers or screens?

- Yes, stainless steel sheets are suitable for architectural louvers or screens due to their durability, corrosion resistance, and aesthetic appeal. They provide a sleek and modern look while also offering protection against weather elements, making them a popular choice for architectural applications.

- Q: Can stainless steel sheets be recycled?

- Yes, stainless steel sheets can be recycled. Stainless steel is a highly recyclable material, and its recycling rate is one of the highest among all materials. When stainless steel sheets reach the end of their useful life, they can be collected and sent to a recycling facility. The recycling process involves melting down the stainless steel sheets and reforming them into new products, without losing their properties or quality. This makes stainless steel a sustainable and environmentally friendly material choice. Recycling stainless steel also helps to conserve natural resources, reduce energy consumption, and minimize waste.

- Q: Stainless steel plate more than the thickness of the wire can not be drawn ah?

- Now all is OK, thick is sanded paper, that grind only, processing cost is high8K can be used in medium plate mill

- Q: What's the drill for stainless steel?

- The cutting fluid is made of concentrated emulsions. Commonly used stainless steel drills are: high cobalt bit (M35 bit, M42 bit), in which the M42 bit is the most cost-effective, and carbide drills are also available.

- Q: Can stainless steel sheets be formed into different shapes?

- Yes, stainless steel sheets can be formed into different shapes through processes such as bending, rolling, and stamping.

- Q: Can stainless steel sheets be used for food preparation surfaces?

- Yes, stainless steel sheets can be used for food preparation surfaces. Stainless steel is a popular choice for food preparation surfaces due to its durability, resistance to corrosion, and ease of cleaning. It is non-reactive with food, making it a safe and hygienic option for food handling.

- Q: What are the different types of stainless steel alloys used for sheets?

- Sheets can be made from various types of stainless steel alloys, each with its own unique properties and applications. Some commonly used stainless steel alloys for sheets include: 1. Austenitic Stainless Steel: This is the most commonly used type of stainless steel, offering excellent corrosion resistance, high ductility, and good formability. It finds applications in food processing, chemical equipment, and architecture. 2. Ferritic Stainless Steel: Ferritic stainless steel alloys are known for their high resistance to stress corrosion cracking and good thermal conductivity. They are commonly used in automotive exhaust systems, heat exchangers, and appliances. 3. Martensitic Stainless Steel: Martensitic stainless steel alloys are known for their high strength, hardness, and wear resistance. They find applications in cutlery, surgical instruments, and turbine blades. 4. Duplex Stainless Steel: Duplex stainless steel alloys combine the properties of both austenitic and ferritic stainless steels. They offer excellent corrosion resistance, high strength, and good weldability. They are commonly used in oil and gas industry equipment, chemical processing, and marine applications. 5. Precipitation-Hardening Stainless Steel: These alloys can be heat treated and provide high strength, good corrosion resistance, and excellent toughness. They are commonly used in aerospace components, the nuclear industry, and high-performance applications. Each stainless steel alloy has its own specific composition and properties, making it suitable for different applications. Factors such as corrosion resistance requirements, strength requirements, and the environment in which the sheets will be used determine the choice of alloy.

- Q: What are the properties of stainless steel sheets?

- Stainless steel sheets possess various properties that make them highly desirable in numerous industries and applications. Firstly, stainless steel sheets exhibit excellent corrosion resistance, making them resistant to rust and staining. This property is primarily due to the presence of chromium in the alloy, which forms a protective oxide layer on the surface, preventing the material from corroding. Additionally, stainless steel sheets are known for their high strength and durability. They have a high tensile strength, allowing them to withstand heavy loads and resist deformation. This strength makes stainless steel sheets suitable for applications that require structural integrity and longevity, such as in construction, automotive, and aerospace industries. Another important property of stainless steel sheets is their heat and fire resistance. They can withstand high temperatures without losing their structural integrity or strength. This makes them ideal for applications that involve exposure to extreme heat, such as in commercial kitchens and industrial furnaces. Furthermore, stainless steel sheets are hygienic and easy to clean, making them suitable for applications in the food and medical industries. Their non-porous surface prevents the growth of bacteria, making them a reliable choice for food processing equipment, surgical instruments, and medical devices. Stainless steel sheets also have an attractive appearance, with a smooth, reflective surface that can be easily maintained. This makes them aesthetically pleasing and suitable for architectural and decorative applications, such as in building facades, interior design, and furniture manufacturing. Lastly, stainless steel sheets are highly versatile and can be easily formed, welded, and fabricated into various shapes and sizes. This flexibility allows for customization and adaptation to specific project requirements, offering designers and engineers a wide range of possibilities. In summary, the properties of stainless steel sheets include corrosion resistance, high strength and durability, heat and fire resistance, hygiene, ease of cleaning, attractive appearance, and versatility. These properties make stainless steel sheets a popular choice across numerous industries, ensuring their widespread use in a vast array of applications.

- Q: What is the Young's modulus of stainless steel sheets?

- The Young's modulus of stainless steel sheets is subject to variation based on the particular grade and composition of the stainless steel. In general, stainless steel possesses a substantial Young's modulus, typically falling within the range of 190 to 220 gigapascals (GPa). Consequently, stainless steel sheets exhibit considerable rigidity and resilience against deformation when subjected to external stress. Nevertheless, it is crucial to acknowledge that the precise Young's modulus can marginally differ due to factors such as temperature, manufacturing techniques, and the specific alloy employed in the stainless steel sheets.

Send your message to us

Stainless steel plate and sheet 304/304L,201,202,310S,316L,316Ti,410,420,444

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t

- Supply Capability:

- 5000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords