Stainless Steel Pipe Stainless Steel Tube 304/316L

- Loading Port:

- Huangpu

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

WELCOME to visit our products here(^_^)

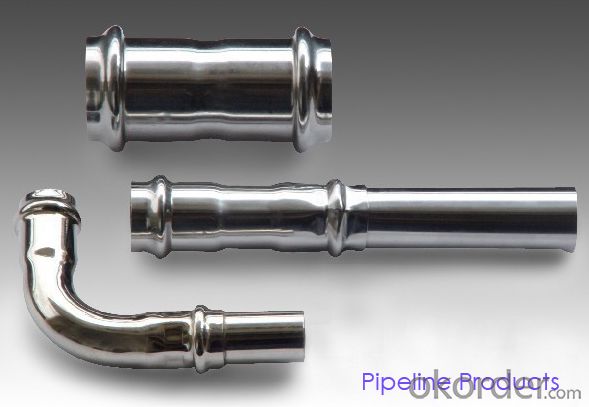

Press fitting system joins pipe without welding or bolting. The components fit by crimping through the use of a special pressing tool. An O-ring that is inserted in the fitting ends of the pipe ensures a leak-proof connection. Press fitting system is the trend of pipeline industry. It is widely used in cold and hot water supply, heating supply, fire protection, medicinal gas, industrial petroleum pipeline system etc.

For the size, now we have 3 series:

1. Out diameters: 16.0, 20.0, 25.4, 32.0, 40.0, 50.8, 63.5, 76.1, 88.9, 108.0 (GB/T 19228.2-2011)

2. Out diameters: 15.88, 22.22, 28.58, 34.0, 42.7, 48.6, 76.1, 88.9, 101.6 (JIS G3448-1980)

3. Out diameters: 15, 18, 22, 28, 35, 42, 54, 76.1, 88.9, 108 (EN 10312:2002)

Technical information:

-- Material: Stainless steel 304 and 316L available.

-- Max working pressure 1.6MPa (equal to 232 psi), testing water pressure: 2.5MPa (equal to 362.5psi).

-- Working temperature from -20 to 110 degree centigrade (with Chlorinated butyl rubber O ring),

-- Suit medium: Cold water, hot water, compressed air, gas, oil etc

The product features as below:

1, thin wall stainless steel pipe could last for 70 years, it is the same life time with normal buildings.

2, no smell, no rusty.

3, recycle material

4, avoid welding, avoid fire dangerous.

Contact us for more details!

- Q: Can stainless steel pipes be used for wastewater treatment systems?

- Yes, stainless steel pipes can be used for wastewater treatment systems. Stainless steel is highly resistant to corrosion, making it a suitable material for handling corrosive wastewater. It is also durable, long-lasting, and easy to maintain, making it an ideal choice for wastewater treatment systems.

- Q: Are stainless steel pipes resistant to scaling and pitting?

- Yes, stainless steel pipes are highly resistant to scaling and pitting due to their inherent corrosion-resistant properties.

- Q: Can stainless steel pipes be used for refrigeration systems?

- Indeed, refrigeration systems can utilize stainless steel pipes. Stainless steel, being an exceedingly robust material, exhibits exceptional resistance against corrosion, rendering it perfectly suitable for deployment in refrigeration systems where both moisture and low temperatures are prevalent. Moreover, stainless steel pipes boast remarkable thermal conductivity, facilitating efficient and effective heat transfer throughout the entire system. Furthermore, stainless steel pipes are effortlessly cleanable and maintainable, while also demonstrating the capacity to withstand significant pressure, thereby making them highly appropriate for deployment in refrigeration systems necessitating unwavering and enduring performance.

- Q: Can stainless steel pipes be coated with PTFE?

- PTFE, also known as polytetrafluoroethylene, can be applied as a coating on stainless steel pipes. This material is highly stable and unreactive, boasting exceptional resistance to chemicals, low friction, and high temperatures. Coating stainless steel pipes with PTFE yields numerous advantages, including reducing friction, preventing corrosion, and enhancing chemical resistance. The PTFE coating creates a smooth surface that is non-stick, facilitating better liquid flow and deterring deposits on the pipe walls. Industries such as chemical processing, food and beverage, pharmaceuticals, and oil and gas benefit greatly from this application, as their pipes are often exposed to aggressive chemicals or high temperatures. Additionally, the PTFE coating offers electrical insulation properties, making it suitable for specific purposes. Ultimately, applying PTFE coating to stainless steel pipes elevates their performance and prolongs their lifespan in various industrial settings.

- Q: What is the difference between electropolished and mechanically polished stainless steel pipes?

- The main difference between electropolished and mechanically polished stainless steel pipes lies in the method used to achieve the desired surface finish. Electropolishing involves immersing the pipe in an electrolyte solution and applying an electric current, which removes a thin layer of metal and impurities, resulting in a smooth, clean, and corrosion-resistant surface. On the other hand, mechanical polishing involves abrasive materials, such as sandpaper or polishing wheels, to physically remove imperfections and create a smooth surface. Both methods can enhance the aesthetics and performance of stainless steel pipes, but electropolishing offers superior cleanliness, corrosion resistance, and a more uniform finish.

- Q: How do you protect stainless steel pipes from external damage?

- To protect stainless steel pipes from external damage, there are several measures you can take: 1. Apply a protective coating: Using a protective coating such as paint or epoxy can help shield the stainless steel pipes from moisture, chemicals, and physical damage. The coating should be selected based on the specific environment and potential risks to ensure maximum protection. 2. Install pipe supports: Properly installing pipe supports can prevent excessive movement and vibration, which can lead to damage over time. Using brackets, clamps, or hangers to secure the pipes in place will minimize the risk of external impacts causing harm. 3. Implement corrosion prevention measures: Stainless steel pipes are resistant to corrosion, but in certain environments, they can still be susceptible to damage. Regularly inspect the pipes for signs of corrosion and promptly address any issues. Applying corrosion inhibitors or using cathodic protection techniques can also help safeguard the pipes from external damage. 4. Use protective guards or covers: In areas where the pipes are exposed to potential impact or physical damage, installing protective guards or covers can provide an additional layer of protection. These guards can be made of materials such as plastic or rubber and can be easily installed or removed as needed. 5. Implement proper handling and storage procedures: During transportation or storage, it is essential to handle stainless steel pipes with care. Avoid dropping or dragging them and ensure they are stored in a clean, dry, and well-ventilated area to prevent moisture buildup and potential damage. By following these measures, you can effectively protect stainless steel pipes from external damage, prolonging their lifespan and ensuring their functionality.

- Q: Are stainless steel pipes suitable for heat exchangers?

- Stainless steel pipes are appropriate for heat exchangers. Stainless steel possesses remarkable heat resistance properties, making it an optimal choice for applications involving elevated temperatures. It is capable of enduring extreme heat without distorting or compromising its structural integrity. Moreover, stainless steel exhibits a high level of resistance against corrosion, which is vital for heat exchangers as they often come into contact with corrosive fluids or environments. This corrosion resistance guarantees the longevity and dependability of the heat exchanger, minimizing the possibility of leaks or malfunctions. Stainless steel pipes also boast exceptional thermal conductivity, facilitating efficient heat transfer between the fluids within the exchanger. All in all, the durability, corrosion resistance, and ability to withstand high temperatures make stainless steel pipes widely employed in heat exchangers.

- Q: Are stainless steel pipes more expensive than other materials?

- Yes, stainless steel pipes are generally more expensive than pipes made from other materials such as PVC or copper.

- Q: Can stainless steel pipes be used for construction?

- Yes, stainless steel pipes can be used for construction. Stainless steel is a durable and corrosion-resistant material, making it suitable for various construction applications such as plumbing, structural support, and drainage systems.

- Q: How do stainless steel pipes compare to carbon fiber pipes?

- Stainless steel pipes and carbon fiber pipes have their own unique characteristics and are used in different applications. Stainless steel pipes are known for their durability and strength. They are highly resistant to corrosion and can withstand high temperatures and pressures. This makes them suitable for various industries such as oil and gas, chemical, and construction. Stainless steel pipes have a longer lifespan and can handle heavy loads, making them a reliable choice for many applications. However, stainless steel pipes are relatively heavy and may require additional support structures. On the other hand, carbon fiber pipes are lightweight and have a high strength-to-weight ratio. They are made from carbon fibers embedded in a resin matrix, resulting in a strong and rigid material. Carbon fiber pipes are commonly used in industries such as aerospace, automotive, and sports equipment. The lightweight nature of carbon fiber pipes allows for increased fuel efficiency in vehicles and improved performance in sports equipment. However, carbon fiber pipes are more expensive than stainless steel pipes and may not be as resistant to extreme temperatures or corrosive environments. In summary, stainless steel pipes are known for their durability and resistance to corrosion, making them suitable for heavy-duty applications. Carbon fiber pipes, on the other hand, are lightweight and offer high strength-to-weight ratio, making them ideal for applications where weight reduction is critical. The choice between stainless steel and carbon fiber pipes ultimately depends on the specific requirements of the application and the trade-offs between cost, weight, and performance.

Send your message to us

Stainless Steel Pipe Stainless Steel Tube 304/316L

- Loading Port:

- Huangpu

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords