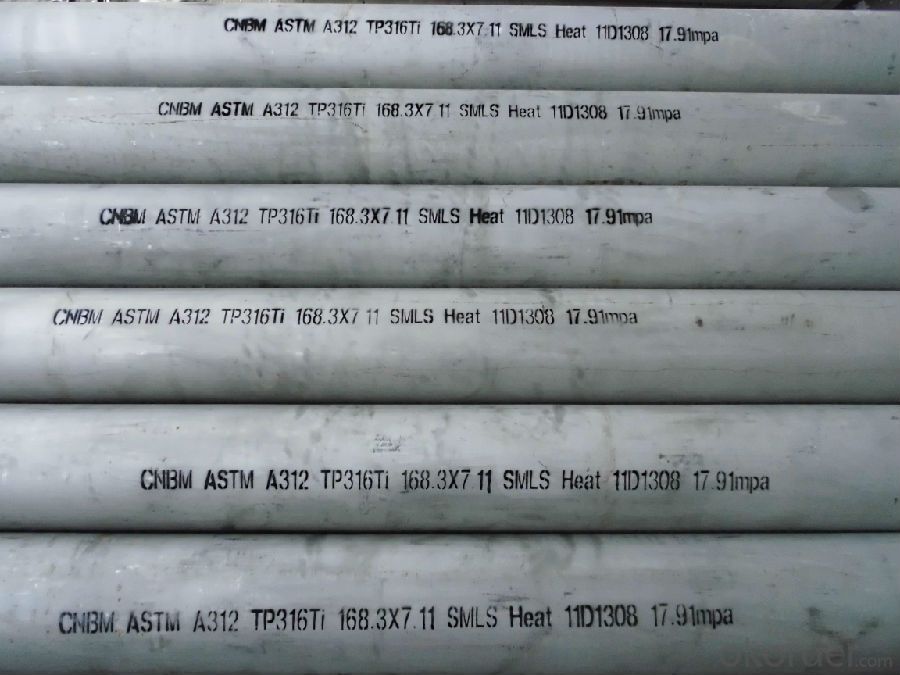

Stainless steel pipe 316Ti 6

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

316Ti stainless steel plate is the addition of Ti in SUS316 steel can improve the resistance to intergranular corrosion resistance.

The chemical composition of 316Ti stainless steel:

C (%): less than 0.08

Si (%): less than 1

Mn (%): less than 2

P (%) is less than or equal to: 0.045

S (%) is less than or equal to 0.03

Cr (%): 16 ~ 18

Ni (%): 10 ~ 14

Mo (%): 2 ~ 3

other (%):

5 (C+N) = Ti = 0.70, N = 0.10

The mechanical properties of 316Ti stainless steel:

YS (Mpa) = 205 TS (Mpa) = 520 EL (%) is more than or equal to 40 Hv 200 degrees

- Q: How do you join stainless steel pipes to other materials?

- Joining stainless steel pipes to other materials can be achieved through several methods, depending on the specific application and requirements. Here are a few common techniques used: 1. Welding: Welding is the most common and effective method for joining stainless steel pipes to other materials. Different types of welding processes such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, or stick welding can be used, depending on the material being joined and the desired strength of the joint. Welding provides a strong and durable bond between stainless steel pipes and other materials. 2. Flanges: Flanges are commonly used to join stainless steel pipes to other materials in applications that require easy disassembly or connection to different equipment. Flanges are typically made from materials such as carbon steel, cast iron, or even stainless steel itself. The flanges are bolted together, creating a secure joint that can be easily disconnected when needed. 3. Threaded connections: Stainless steel pipes can also be joined to other materials using threaded connections. This method is often used for smaller diameter pipes or when the pipes need to be easily removed or replaced. The threaded connections can be made using pipe fittings such as couplings, unions, or adapters, which have male and female threads that screw together to form a tight seal. 4. Compression fittings: Compression fittings are another option for joining stainless steel pipes to other materials. These fittings consist of a compression nut, a ferrule, and a body that houses the ferrule. The ferrule is compressed onto the pipe, creating a tight seal when the compression nut is tightened. Compression fittings provide a reliable and leak-free joint between stainless steel pipes and other materials. 5. Mechanical connectors: In some cases, mechanical connectors can be used to join stainless steel pipes to other materials. These connectors typically involve clamping or fastening mechanisms that secure the pipes together without the need for welding or threading. Mechanical connectors can be a suitable option in situations where disassembly and reassembly are required. It is important to consider the specific application, material compatibility, and the required strength and durability of the joint when selecting the appropriate method to join stainless steel pipes to other materials. Consulting with a professional or referring to industry standards and guidelines is recommended to ensure a proper and reliable connection.

- Q: Can stainless steel pipes be used for construction purposes?

- Yes, stainless steel pipes can be used for construction purposes. Stainless steel is known for its durability, corrosion resistance, and strength, making it suitable for various construction applications such as plumbing, structural support, and transportation of fluids and gases.

- Q: What is the difference between 347 and 347H stainless steel pipes?

- The carbon content is the main distinguishing factor between 347 and 347H stainless steel pipes. In the case of 347 pipes, the maximum carbon content is 0.08%, while 347H pipes have a higher carbon content range of 0.04-0.10%. This increased carbon content in 347H pipes contributes to enhanced strength at high temperatures and greater resistance to sensitization, which is the formation of chromium carbides at grain boundaries that can lead to intergranular corrosion. Because of its higher carbon content, it is generally recommended to use 347H stainless steel pipes for applications involving elevated temperatures and thermal cycling. These pipes exhibit improved resistance to creep and can withstand higher levels of stress compared to 347 stainless steel pipes. Industries such as chemical processing, petrochemical, and power generation commonly employ 347H pipes due to their exposure to high temperatures and corrosive environments. To summarize, the disparity between 347 and 347H stainless steel pipes rests in their carbon content. 347H pipes offer superior strength at high temperatures and resistance to sensitization. The choice between the two depends on the specific requirements and conditions of the application.

- Q: How do you prevent condensation in stainless steel pipes?

- To prevent condensation in stainless steel pipes, it is important to insulate the pipes properly. This can be done by using insulation materials specifically designed for pipes, such as foam or fiberglass insulation. Additionally, ensuring that the pipes are properly sealed and free from any leaks will also help minimize condensation. Proper ventilation in the area around the pipes can also help reduce moisture buildup and prevent condensation from occurring.

- Q: What is the difference between 304LN and 316LN stainless steel pipes?

- The main difference between 304LN and 316LN stainless steel pipes lies in their composition and the addition of certain elements. 304LN stainless steel is an austenitic stainless steel that contains low carbon content and nitrogen. It is designed to provide improved strength and corrosion resistance compared to standard 304 stainless steel. The addition of nitrogen promotes the formation of a stable austenite phase, which enhances the material's mechanical properties. On the other hand, 316LN stainless steel is also an austenitic stainless steel but contains molybdenum and a higher nickel content compared to 304LN. The addition of molybdenum increases the material's resistance to pitting corrosion caused by chlorides and other aggressive environments. The higher nickel content further enhances the corrosion resistance and makes it suitable for more demanding applications, such as marine environments or chemical processing. In summary, while both 304LN and 316LN stainless steel pipes are austenitic and offer good corrosion resistance, the addition of molybdenum and higher nickel content in 316LN makes it more suitable for applications where enhanced corrosion resistance is required, especially in aggressive environments.

- Q: Stainless steel pipe drilling?

- Acid resistant stainless steel is stainless steel, the resistance of air, steam, water and other weak corrosive medium or with stainless steel known as stainless steel; while the resistance to chemical corrosion (acid, alkali and salt chemical etching) corrosion of steel called acid resistant steel. Because of the difference in the chemical composition of the two, and make their corrosion resistance is different, ordinary stainless steel is generally not resistant to chemical medium corrosion, and acid resistant steel are generally stainless steel.

- Q: How can the stainless steel tube eliminate stress?

- After heating 500 degrees, placed at room temperature or placed at room temperature for more than 2 years

- Q: What is the difference between 304J1 and 316J1 stainless steel pipes?

- The main difference between 304J1 and 316J1 stainless steel pipes lies in their composition and properties. 304J1 stainless steel is a variant of 304 stainless steel, which contains a higher percentage of manganese to enhance its formability and reduce the risk of strain hardening during fabrication. This makes it more suitable for certain applications where deep drawing or severe bending is required. However, it is less corrosion-resistant compared to 316J1 stainless steel. On the other hand, 316J1 stainless steel is a variant of 316 stainless steel, which contains a higher percentage of nitrogen to improve its strength and corrosion resistance. It also has slightly better resistance to pitting and crevice corrosion in chloride environments. Therefore, 316J1 stainless steel pipes are often preferred in applications where higher corrosion resistance is required, such as marine environments or chemical processing plants. In summary, while both 304J1 and 316J1 stainless steel pipes are suitable for various applications, the choice between them depends on the specific needs of the project, including the level of corrosion resistance required and the fabrication processes involved.

- Q: What are the advantages of using stainless steel pipes in the automotive industry?

- Stainless steel pipes offer numerous benefits when utilized in the automotive industry. Firstly, their exceptional resistance to corrosion ensures long-lasting durability. This is especially crucial in vehicles exposed to diverse environmental conditions, such as rain, snow, and road salt. By incorporating stainless steel pipes, manufacturers can guarantee that the exhaust system and other components remain in optimal condition for an extended period. Secondly, stainless steel pipes exhibit remarkable resistance to high temperatures. They can endure the extreme heat generated by the engine and exhaust system without corroding or deforming. Consequently, they are suitable for various vehicle parts, including exhaust manifolds, catalytic converters, and mufflers. Moreover, stainless steel pipes possess superior strength and impact resistance. They can withstand intense vibrations and shocks experienced during vehicle operation. This is vital for preserving the structural integrity of the vehicle and preventing potential failures or leaks. Additionally, stainless steel pipes offer excellent formability, enabling easy shaping and fabrication into complex designs. This versatility makes them suitable for various automotive applications, such as fuel lines, coolant systems, and hydraulic systems. Their malleability also reduces the requirement for additional components, resulting in cost savings during the manufacturing process. Furthermore, stainless steel pipes enhance the aesthetic appeal of vehicles. They provide a sleek and polished appearance that elevates the overall design. This is particularly significant for luxury vehicles and sports cars, where visual appeal plays a substantial role in attracting customers. Lastly, stainless steel pipes are environmentally friendly. They possess high scrap value and can be recycled without compromising quality. This promotes sustainability and reduces the demand for new raw materials, making them an eco-friendly choice for the automotive industry. In conclusion, the utilization of stainless steel pipes in the automotive industry offers advantages such as corrosion resistance, high-temperature resistance, strength and impact resistance, formability, aesthetic appeal, and environmental sustainability. These benefits establish stainless steel pipes as the preferred choice for various applications, contributing to the overall reliability and performance of vehicles.

- Q: Can stainless steel pipes handle high temperatures?

- Stainless steel pipes possess the ability to endure high temperatures. The exceptional heat resistance of stainless steel makes it suitable for a wide range of applications involving elevated temperatures. The maximum temperature the pipes can withstand is determined by the specific grade of stainless steel employed. For example, austenitic stainless steel grades like 304 and 316 are typically capable of handling temperatures up to approximately 1600°F (870°C), whereas higher alloyed grades such as 310 and 321 can withstand even higher temperatures. This heat resistance is attributed to the presence of chromium and other alloying elements in stainless steel, which create a protective oxide layer that prevents corrosion and oxidation at high temperatures. Consequently, stainless steel pipes find common use in industries like petrochemical, power generation, and heat exchangers, where high temperatures are prevalent.

Send your message to us

Stainless steel pipe 316Ti 6

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords