6 inch Welded Stainless Steel Pipe 316l handrails

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

C | Si | Mn | P | S | Ni | Cr | |

| SS304 | 0.046 | 0.316 | 1.481 | 0.0424 | 0.0028 | 8.001 | 18.019 |

| SS201 | 0.111 | 0.31 | 9.45 | 0.029 | 0.006 | 0.871 | 14.110 |

| SS316 | ≤0.08 | ≤1 | ≤2 | 0.035 | 0.03 | 1.0~14.0 | 16.0~18.5 |

Shape | Round / Square Etc. |

Brand | PEMCO/OEM/ODM |

Material | SS Stainless Steel 201, 304 , 316 |

Quality | First Grade |

Finish | Satin/Mirror |

Technology | Casting |

Certificate | ISO 9001-2000 |

Application | *Construction And Stair , Handrail , Railing Use |

*Shopping Mall,House,Outdoor | |

Feature | Beautiful Outlook, Easy To Clean, Low Maintenance Cost |

Usage | Widely Used On Stainless Steel Balustrade & Handrails, Indoor Or Outdoor Decorations,Etc. |

MOQ | 10 Pieces |

Delivery Time | 15-20 Days |

Colors for you to choose:

hot sale

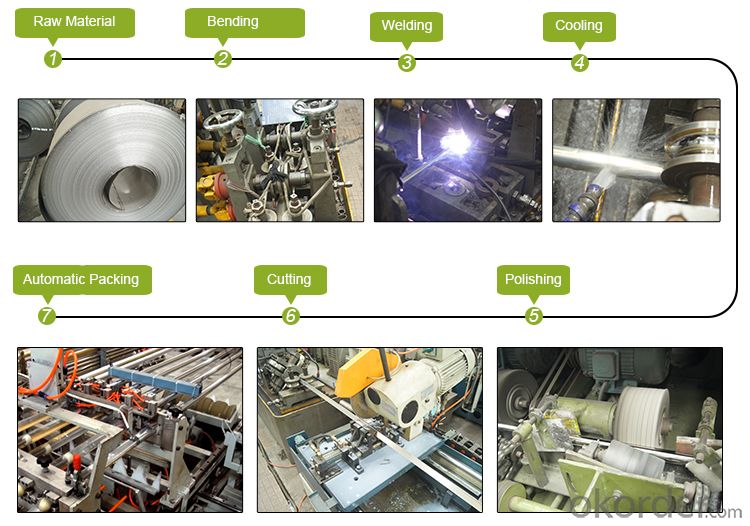

Production Process

Our Services

Pre-sale service:

1. Quotation: stainless steel pipe handrails price will be quoted according to material grade, size, thickness, length of each piece, finish and your quantity you want.

2. Sample: free samples can be sent for your reference.

3. OEM/ ODM Service: Your 2D/3D drawings or samples are welcome.

4. Other reasonable requests: factory photos, test reports, certifications, etc. to show.

Sale service:

1. Payment Method:

For samples, freight can be paid via Paypal, Westernunion or to our bank account.

Deposit and the balance can be paid via bank account or Alibaba Onetouch.

2. Business Term: EXW, FOB, CIF, etc.

3. Delivery: To door service - Internationl Express (DHL, FedEx, TNT, etc.)

Airport or shipping transportation

4. Payment and Shipping Terms:

Alibaba Onetouch Paypal Western Union Bank Transfer

- Q: What are the different types of stainless steel pipe fittings?

- Various piping systems commonly use several different types of stainless steel pipe fittings. Some of the most frequently used ones are: 1. Stainless Steel Elbows: These fittings alter the pipe's direction by either 90 degrees or 45 degrees. They come in various angles and sizes to accommodate the specific requirements of the piping system. 2. Stainless Steel Tees: Tees create a branch in the pipeline, enabling the fluid flow in multiple directions. They possess three openings, with one inlet and two outlets. 3. Stainless Steel Couplings: Couplings connect two pipes of the same diameter. They come in different variants, including full coupling (both ends are threaded), half coupling (only one end is threaded), and reducing coupling (for connecting pipes of different diameters). 4. Stainless Steel Reducers: Reducers join pipes of varying diameters. They are available in two types: concentric reducers (tapered on both ends) and eccentric reducers (tapered on one end only). 5. Stainless Steel Caps: Caps seal the end of a pipe and are commonly used when further extension of the pipe is unnecessary. 6. Stainless Steel Crosses: Crosses resemble tees but have four openings instead of three. They create a branch in the pipeline with multiple outlets. 7. Stainless Steel Unions: Unions connect two pipes without the need for threading. They offer a convenient way to disassemble and reassemble the pipes for maintenance or repairs. 8. Stainless Steel Nipples: Nipples are short pipe sections with male threaded ends. They extend a pipe or facilitate a connection between two female threaded fittings. It is important to note that these examples represent only a fraction of the diverse range of stainless steel pipe fittings available. The specific fitting required depends on factors such as the application, pipe size, and other considerations.

- Q: Can stainless steel pipes be used in the automotive industry?

- Yes, stainless steel pipes can be used in the automotive industry. Stainless steel is a highly durable and corrosion-resistant material, making it ideal for various applications in the automotive sector. Stainless steel pipes are commonly used in exhaust systems, where they can withstand high temperatures and resist the corrosive effects of gases and condensation. Additionally, stainless steel pipes are also used in fuel delivery systems, brake lines, and hydraulic systems, where their strength and resistance to corrosion are essential. Overall, stainless steel pipes offer excellent performance and longevity in the demanding conditions of the automotive industry.

- Q: How are stainless steel pipes manufactured?

- Stainless steel pipes are manufactured through a multi-step process that involves various stages of fabrication and shaping. The manufacturing process begins with the selection of high-quality stainless steel, usually in the form of sheets or coils. These steel sheets are thoroughly inspected for any defects or imperfections before being cut into the desired length or size. Once the sheets are cut, they are fed into a forming machine where they are rolled into the shape of a cylindrical tube. This process is known as cold rolling, and it helps to give the pipe its initial shape and thickness. The rolled sheets are then welded together using either a high-frequency induction welding technique or a submerged arc welding method. Both methods ensure a strong and durable weld joint. After the welding process, the pipe goes through a series of finishing treatments to improve its appearance and physical properties. The first step is to remove any excess weld material using a trimming machine. This ensures a smooth and even surface along the length of the pipe. Next, the pipe is subjected to a heat treatment called annealing. Annealing helps to relieve internal stresses and improve the pipe's mechanical properties. It also enhances the corrosion resistance of the stainless steel. Following annealing, the pipe may undergo additional processes such as pickling and passivation. Pickling involves immersing the pipe in an acid solution to remove surface impurities and oxides. Passivation, on the other hand, involves treating the pipe with a chemical solution to create a protective oxide layer on its surface, enhancing its resistance to corrosion. Once the finishing treatments are complete, the pipes are cut to the desired length and undergo a final inspection for quality assurance. This involves checking dimensions, surface finish, weld integrity, and overall appearance. In conclusion, stainless steel pipes are manufactured through a meticulous process that includes cutting, forming, welding, finishing treatments, and quality control measures. This ensures that the pipes meet the required standards and exhibit excellent properties such as strength, durability, and corrosion resistance.

- Q: What is the difference between Type 409 and Type 410 stainless steel pipes?

- Type 409 and Type 410 stainless steel pipes exhibit distinct characteristics and are used for different purposes. Type 409 stainless steel is a ferritic variant containing less chromium than Type 410. It is mainly composed of iron, carbon, and up to 11% chromium. This composition grants Type 409 stainless steel adequate resistance to corrosion in low-oxygen environments and moderate resistance to pitting and crevice corrosion. It finds common usage in applications where high-temperature oxidation resistance is unnecessary, such as automotive exhaust systems, catalytic converter shells, and heat exchangers. On the contrary, Type 410 stainless steel is a martensitic variant with a higher chromium content (around 11-13%) and a small amount of nickel. This composition endows Type 410 stainless steel with exceptional corrosion resistance and favorable mechanical properties. It is a versatile stainless steel that can be subjected to heat treatment to achieve elevated strength and hardness. Type 410 stainless steel is frequently employed in applications requiring corrosion resistance and/or wear resistance, including cutlery, surgical instruments, valves, and pump parts. To summarize, the primary distinction between Type 409 and Type 410 stainless steel pipes lies in their composition and resulting properties. Type 409 stainless steel is a ferritic variant with good corrosion resistance in low-oxygen environments, whereas Type 410 stainless steel is a martensitic variant with excellent corrosion resistance, heightened strength, and hardness. The choice between these two types of stainless steel pipes depends on the specific requirements of the application and the desired properties necessary for its success.

- Q: How do you pressure test stainless steel pipes?

- To pressure test stainless steel pipes, you can use various methods, such as hydrostatic testing or pneumatic testing. Hydrostatic testing involves filling the pipes with water or another suitable liquid and pressurizing them to a specified level using a pump. The pressure is then maintained for a designated period to check for any leaks or failures. Pneumatic testing, on the other hand, involves using compressed air or gas to pressurize the pipes and conducting similar leak detection procedures. It is crucial to follow industry standards, guidelines, and safety measures while performing these tests to ensure the integrity and reliability of the stainless steel pipes.

- Q: Are stainless steel pipes resistant to chemicals?

- Stainless steel pipes are generally resistant to chemicals, thanks to their corrosion resistance properties. This quality makes stainless steel an ideal material for various applications, including pipes that come into contact with different chemicals. The presence of high levels of chromium in stainless steel forms a protective layer on its surface, preventing it from reacting with most chemicals and corrosive substances. However, it is important to consider that the resistance of stainless steel pipes to chemicals can vary depending on the specific type and grade of stainless steel used. In certain cases, aggressive chemicals or extreme conditions may still cause corrosion or damage to stainless steel pipes. Therefore, it is always recommended to seek advice from experts or refer to chemical resistance charts for accurate information regarding the compatibility of stainless steel pipes with different chemicals.

- Q: Can stainless steel pipes be used for structural applications?

- Yes, stainless steel pipes can be used for structural applications. Stainless steel is known for its high strength-to-weight ratio, corrosion resistance, and durability, making it a suitable material for various structural applications. Stainless steel pipes are commonly used in construction, infrastructure, and industrial projects, where the pipe's strength and resistance to corrosion are crucial. They are often used for structural supports, frameworks, and load-bearing applications in buildings, bridges, stadiums, and other structures. Additionally, stainless steel pipes have excellent structural integrity, allowing them to withstand heavy loads, extreme temperatures, and harsh environmental conditions. Therefore, stainless steel pipes are a reliable choice for structural applications.

- Q: Can stainless steel pipes be used for gas pipelines?

- Yes, stainless steel pipes can be used for gas pipelines. Stainless steel is highly resistant to corrosion and can withstand high pressure and temperature conditions, making it suitable for carrying gases safely and efficiently. Additionally, stainless steel pipes are durable and have a long lifespan, making them a reliable choice for gas transportation.

- Q: Are stainless steel pipes resistant to crevice corrosion?

- Yes, stainless steel pipes are generally resistant to crevice corrosion. This is because stainless steel contains a significant amount of chromium which forms a passive oxide layer on the surface of the material. This oxide layer acts as a protective barrier and prevents the penetration of corrosive substances, including crevices. However, it is important to note that the resistance to crevice corrosion may vary depending on the specific grade and composition of stainless steel used, as well as the environment in which the pipes are exposed to. Therefore, it is always advisable to select the appropriate grade of stainless steel that is suitable for the specific application and environment to ensure optimal resistance to crevice corrosion.

- Q: Can stainless steel pipes be insulated with ceramic?

- Ceramic can indeed be used to insulate stainless steel pipes. It is commonly utilized in industrial settings that involve high temperatures. Ceramic insulation offers exceptional heat resistance and thermal insulation properties, making it an excellent choice. It can withstand extreme temperatures and effectively reduces heat transfer. Various industries utilize ceramic insulation to insulate pipes, tanks, furnaces, and other equipment. When applied to stainless steel pipes, ceramic insulation helps maintain the fluid's temperature, preventing heat loss or gain. Additionally, it provides protection against corrosion and mechanical damage. In summary, ceramic insulation is a suitable option for insulating stainless steel pipes in a wide range of applications.

Send your message to us

6 inch Welded Stainless Steel Pipe 316l handrails

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords