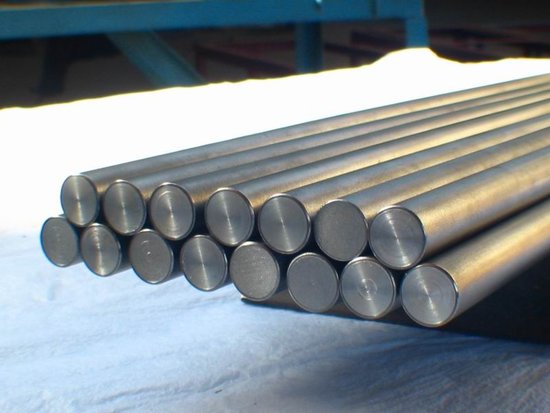

316Ti Stainless Steel Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Bar

Stainless Steel Round Bright Bar

Hot-rolled Stainless Steel Black Bar

Grades:201、202、301、302、303、304、316、316L、321 etc

|

Diameter (mm) |

weight (kg/m) |

Diameter (mm) |

weight (kg/m) |

Diameter (mm) |

weight (kg/m) |

Diameter (mm) |

weight (kg/m) |

|

2 |

0.025 |

14 |

1.221 |

30 |

5.607 |

50 |

15.575 |

|

3 |

0.056 |

15 |

1.402 |

32 |

6.38 |

55 |

18.846 |

|

4 |

0.1 |

16 |

1.595 |

34 |

7.202 |

60 |

22.428 |

|

5 |

0.156 |

18 |

2.019 |

35 |

7.632 |

65 |

26.322 |

|

6 |

0.224 |

19 |

2.249 |

36 |

8.074 |

70 |

30.527 |

|

7 |

0.305 |

20 |

2.492 |

38 |

8.996 |

75 |

35.044 |

|

8 |

0.399 |

22 |

3.015 |

40 |

9.968 |

80 |

39.872 |

|

9 |

0.505 |

24 |

3.588 |

42 |

10.99 |

85 |

45.012 |

|

10 |

0.623 |

25 |

3.894 |

45 |

12.616 |

90 |

50.463 |

|

11 |

0.754 |

27 |

4.542 |

46 |

13.183 |

95 |

56.226 |

|

12 |

0.897 |

28 |

4.884 |

48 |

14.354 |

100 |

62.3 |

- Q: Are stainless steel bars resistant to radiation?

- Yes, stainless steel bars are generally resistant to radiation. Stainless steel is a type of steel alloy that contains chromium, which provides excellent corrosion resistance. This corrosion resistance also extends to radiation exposure. Stainless steel is known for its ability to withstand various forms of radiation, including gamma rays and X-rays, without significant damage or degradation. This property makes stainless steel bars a suitable choice for applications where radiation resistance is required, such as in nuclear power plants, medical and laboratory equipment, and aerospace industry. However, it is important to note that the resistance of stainless steel to radiation can vary depending on the specific alloy composition and the intensity and duration of the radiation exposure.

- Q: What are the different types of stainless steel bars used in agricultural equipment?

- There are several different types of stainless steel bars used in agricultural equipment, including 304, 316, and 410 stainless steel. 304 stainless steel is commonly used for general-purpose applications, while 316 stainless steel is more corrosion resistant and often used in environments with high exposure to moisture or chemicals. 410 stainless steel is known for its high strength and durability, making it suitable for heavy-duty applications in agricultural equipment.

- Q: Can stainless steel bars be used in tennis racket frames?

- Yes, stainless steel bars can be used in tennis racket frames. Stainless steel is a strong and durable material that can provide stability and support to the racket frame, making it suitable for use in tennis rackets.

- Q: What are the different types of stainless steel bars used in musical instruments?

- There are several different types of stainless steel bars that are commonly used in musical instruments. One of the most commonly used types is 304 stainless steel, which is known for its excellent corrosion resistance and high strength. This type of stainless steel bar is often used in instruments such as drums, cymbals, and other percussion instruments. Another type of stainless steel bar commonly found in musical instruments is 316 stainless steel. This particular grade of stainless steel is highly resistant to corrosion and is often used in instruments that are exposed to moisture, such as brass instruments like trumpets and trombones. In addition to these two popular grades, there are also other types of stainless steel bars used in musical instruments. For instance, 430 stainless steel is often used in the construction of saxophones due to its high heat resistance and excellent durability. Furthermore, 17-4 PH stainless steel is another type that is commonly used in the construction of guitar strings due to its high tensile strength and resistance to wear. Overall, the choice of stainless steel bar used in musical instruments depends on the specific requirements of the instrument and the desired characteristics, such as corrosion resistance, strength, and durability. Each type of stainless steel offers its own unique set of qualities, ensuring that the instrument meets the necessary standards and delivers the desired sound quality.

- Q: Are stainless steel bars suitable for the oil and gas industry?

- Yes, stainless steel bars are highly suitable for the oil and gas industry. Stainless steel is known for its excellent corrosion resistance, making it ideal for applications in oil and gas environments that are prone to exposure to harsh chemicals, high temperatures, and corrosive substances. Stainless steel bars are highly resistant to rust, oxidation, and corrosion, ensuring their durability and longevity in the demanding conditions of the industry. Moreover, stainless steel bars offer exceptional strength and toughness, enabling them to withstand the high pressure and mechanical stresses often found in oil and gas operations. They exhibit excellent mechanical properties, including high tensile strength and hardness, which make them well-suited for use in critical components such as pipelines, valves, fittings, and other equipment. Stainless steel bars also possess good thermal conductivity, allowing them to efficiently transfer heat and withstand temperature variations. This is particularly important in the oil and gas industry where extreme temperatures are often encountered. Additionally, stainless steel is non-magnetic, making it suitable for applications where magnetic interference could be detrimental. Furthermore, stainless steel is a low-maintenance material that requires minimal upkeep and has a long service life, reducing downtime and costs associated with maintenance and replacements. Its hygienic properties and resistance to contamination make it suitable for applications involving the transportation and storage of oil and gas. Overall, stainless steel bars provide the oil and gas industry with a reliable and cost-effective solution due to their exceptional corrosion resistance, mechanical strength, thermal conductivity, and low-maintenance properties. These factors make stainless steel bars an excellent choice for a wide range of applications in the oil and gas sector.

- Q: Can stainless steel bars be plated or coated?

- Yes, stainless steel bars can be plated or coated. Plating or coating stainless steel bars can enhance their appearance, provide corrosion resistance, or improve their performance in specific applications.

- Q: How do stainless steel bars resist sulfuric acid?

- Stainless steel bars are known for their exceptional resistance to various corrosive substances, including sulfuric acid. This resistance can be attributed to the unique composition of stainless steel, which contains a minimum of 10.5% chromium. The presence of chromium in stainless steel forms a protective layer on its surface, known as a passive film. When stainless steel bars come into contact with sulfuric acid, the passive film acts as a barrier, preventing the acid from directly attacking the underlying metal. This film is self-healing, meaning that if it is damaged or removed, it can quickly reform when exposed to oxygen. This enables stainless steel bars to maintain their corrosion resistance even in the presence of sulfuric acid. Furthermore, the high chromium content in stainless steel provides additional protection against sulfuric acid. Chromium has an inherent ability to react with oxygen in the air, forming a thin, invisible oxide layer on the surface of stainless steel. This oxide layer further enhances the resistance of stainless steel bars to sulfuric acid, as it acts as an additional barrier between the acid and the metal. Overall, the combination of the passive film and the oxide layer formed by chromium allows stainless steel bars to withstand the corrosive effects of sulfuric acid, making them a durable and reliable choice for applications where resistance to this acid is essential.

- Q: Can stainless steel bars be powder coated?

- Yes, stainless steel bars can be powder coated. Powder coating is a popular finishing technique used to enhance the appearance and durability of various metal surfaces, including stainless steel.

- Q: Do stainless steel bars require any surface treatment?

- Yes, stainless steel bars often require surface treatment to enhance their corrosion resistance and improve their appearance. One common surface treatment method is passivation, which involves removing any contaminants or impurities from the surface of the stainless steel and promoting the formation of a protective oxide layer. This process helps to prevent corrosion and maintain the integrity of the stainless steel bars. Additionally, surface treatments such as electropolishing or mechanical polishing can be applied to improve the appearance and smoothness of the bars, making them more visually appealing and easier to clean. Ultimately, the need for surface treatment depends on the specific application and desired outcome for the stainless steel bars.

- Q: What are the different surface finishes available for stainless steel bars?

- Some of the different surface finishes available for stainless steel bars include mill finish, brushed finish, mirror finish, and satin finish.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$8 million |

| Main Markets | East Asia, Middle East, West Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | above 50 people |

| Language Spoken: | English, Chinese, Arabic |

| b) Factory Information | |

| Factory Size: | about 15000 square meter |

| No. of Production Lines | above 4 |

| Contract Manufacturing | OEM Service Offered,Design Service Offered |

| Product Price Range | Average |

Send your message to us

316Ti Stainless Steel Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords