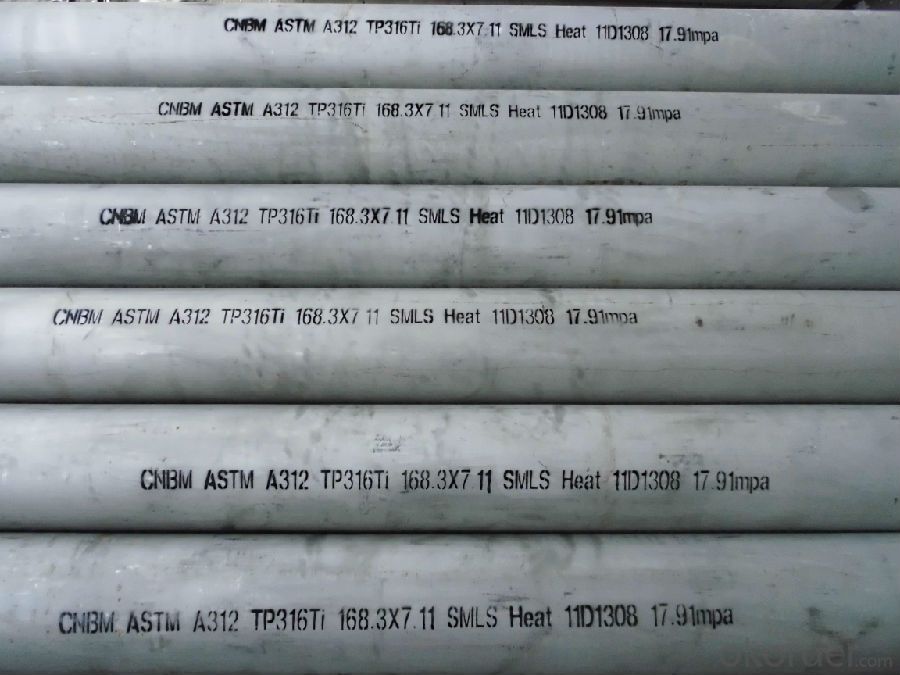

Stainless steel pipe 316Ti 3

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

316Ti stainless steel plate is the addition of Ti in SUS316 steel can improve the resistance to intergranular corrosion resistance.

The chemical composition of 316Ti stainless steel:

C (%): less than 0.08

Si (%): less than 1

Mn (%): less than 2

P (%) is less than or equal to: 0.045

S (%) is less than or equal to 0.03

Cr (%): 16 ~ 18

Ni (%): 10 ~ 14

Mo (%): 2 ~ 3

other (%):

5 (C+N) = Ti = 0.70, N = 0.10

The mechanical properties of 316Ti stainless steel:

YS (Mpa) = 205 TS (Mpa) = 520 EL (%) is more than or equal to 40 Hv 200 degrees

- Q: What is the difference between seamless and LSAW stainless steel pipes?

- Seamless and LSAW (Longitudinal Submerged Arc Welding) stainless steel pipes are two common types of pipes used in various industries. The main difference between these pipes lies in their manufacturing process and resulting structural characteristics. Seamless stainless steel pipes are manufactured without any seams or welds. They are made by piercing a solid cylindrical billet and then extruding it to form a hollow tube. This process ensures a uniform cross-section throughout the pipe, resulting in a smooth and consistent inner and outer surface. The absence of welds eliminates the potential weak points and increases the overall strength and integrity of the pipe. Seamless pipes are generally considered to have superior corrosion resistance and are often preferred in critical applications where leak-free performance is essential. On the other hand, LSAW stainless steel pipes are made by bending and welding a steel plate or coil into a cylindrical shape. The longitudinal seam is created through a submerged arc welding process, where an electric arc is passed through the steel plate and the welding filler material. This welding technique results in a visible seam on the outside of the pipe. LSAW pipes are commonly used for large diameter and thick-walled applications, such as in oil and gas transportation, as they can be produced in longer lengths and with larger diameters than seamless pipes. In terms of cost, seamless stainless steel pipes are generally more expensive to produce than LSAW pipes due to the complex manufacturing process. However, the seamless construction offers better performance and reliability, making it a preferred choice for critical applications. LSAW pipes, on the other hand, provide a cost-effective solution for large-scale projects where the visible seam is not a concern. In summary, the key differences between seamless and LSAW stainless steel pipes lie in their manufacturing process, structural characteristics, and cost. Seamless pipes are made without any seams or welds, providing superior corrosion resistance and strength. LSAW pipes, on the other hand, are created by bending and welding a steel plate, offering a cost-effective solution for large-scale projects. The choice between these two types of pipes depends on the specific requirements of the application and the desired balance between cost and performance.

- Q: Stainless steel pipe specification 25*2 what does it mean?

- Outside diameter 25MM, wall thickness 2MM, this tube is too thick, our company has thin wall stainless steel tube

- Q: Can stainless steel pipes be used for automotive exhaust systems?

- Yes, stainless steel pipes can be used for automotive exhaust systems. Stainless steel is a popular material choice for exhaust systems due to its high corrosion resistance, durability, and ability to withstand high temperatures. It helps in preventing rust and prolonging the lifespan of the exhaust system, making it a suitable option for automotive applications.

- Q: Are stainless steel pipes suitable for mining applications?

- Yes, stainless steel pipes are suitable for mining applications. Stainless steel is a durable and corrosion-resistant material that can withstand harsh and demanding environments commonly found in mining operations. It offers excellent resistance to corrosion, abrasion, and high temperatures, making it ideal for transporting various materials such as water, chemicals, and minerals in the mining industry. Stainless steel pipes are also known for their strength and ability to handle high-pressure conditions, which is crucial in mining applications. Additionally, stainless steel is non-reactive and does not release harmful substances into the materials being transported, ensuring the safety and purity of the mining processes. Overall, stainless steel pipes are a reliable and long-lasting choice for mining applications due to their durability, corrosion resistance, and ability to withstand extreme conditions.

- Q: Can stainless steel pipes be used for construction?

- Certainly, construction can utilize stainless steel pipes. Stainless steel, being an incredibly durable and corrosion-resistant material, is well-suited for a wide range of construction applications. It is frequently employed in plumbing systems, water supply lines, and underground piping where the ability to resist corrosion is of utmost importance. Moreover, stainless steel pipes are utilized in the construction of bridges, buildings, and infrastructure projects due to their robustness and capacity to withstand harsh weather conditions. Furthermore, the aesthetic appeal and minimal upkeep requirements of stainless steel make it a preferred choice for architectural designs. In conclusion, stainless steel pipes are a dependable and enduring option for construction purposes.

- Q: Can stainless steel pipes be used for marine applications?

- Indeed, stainless steel pipes possess the capability to be utilized in marine applications. Renowned for its ability to resist corrosion, stainless steel emerges as an optimal substance to employ within marine surroundings, perpetually exposed to saltwater and elevated humidity levels. By being resistant to both rust and corrosion, stainless steel pipes guarantee their robustness and enduring nature when employed in marine applications. In the marine industry, they find extensive usage for a multitude of purposes, including piping systems, exhaust systems, and structural components. Furthermore, stainless steel pipes exhibit the capacity to endure extreme temperatures and pressures, rendering them suitable for the arduous conditions frequently encountered in marine applications.

- Q: How do you pressure test stainless steel pipes?

- To ensure the integrity and safety of stainless steel pipes, it is crucial to conduct pressure testing. Below is a step-by-step guide on how to perform pressure testing on stainless steel pipes: 1. Pipe Preparation: Before initiating the pressure test, make sure the stainless steel pipes are clean and devoid of any debris or contaminants. Inspect the pipes for visible defects like cracks or leaks and repair or replace them if necessary. 2. Gathering the Necessary Equipment: You will require a pressure testing pump or equipment capable of generating the desired pressure, pressure gauges, and appropriate seals or plugs to seal the pipe ends. 3. Determining the Required Pressure: Refer to engineering specifications or relevant industry standards to determine the suitable pressure for testing the stainless steel pipes. The pressure is usually indicated in pounds per square inch (psi). 4. Sealing the Pipe Ends: Use suitable seals or plugs to securely seal all the ends of the stainless steel pipes. This will prevent any leakage during the pressure test. 5. Connecting the Pressure Testing Equipment: Connect the pressure testing pump or equipment to one end of the pipe using a pressure gauge to accurately monitor the pressure. Ensure that the connections are tight and leak-proof. 6. Applying Pressure Gradually: Gradually increase the pressure in the stainless steel pipes using the pressure testing pump or equipment. Keep a close eye on the pressure gauge and ensure it reaches and stabilizes at the desired testing pressure. This gradual process avoids sudden pressure surges that could potentially damage the pipes. 7. Maintaining the Pressure: Maintain the pressure at the desired level for a specified duration as recommended by engineering specifications or standards. The duration can vary from a few minutes to several hours depending on the application and requirements. 8. Leak Inspection: While maintaining the pressure, carefully inspect the stainless steel pipes for any signs of leakage. Look for visible leaks, listen for hissing sounds, or use leak-detection solution or soapy water to identify any escaping air or bubbles. If leaks are detected, halt the pressure test and address the issue before proceeding. 9. Releasing the Pressure: Once the pressure test is completed, gradually release the pressure from the stainless steel pipes using the pressure testing pump or equipment. Be cautious while releasing the pressure to prevent sudden decompression that could potentially damage the pipes. 10. Evaluating the Results: After the pressure test, inspect the stainless steel pipes again to ensure no new leaks or defects have emerged. If the pipes have successfully passed the pressure test without any issues, they can be considered safe and suitable for their intended application. It is important to note that pressure testing stainless steel pipes should only be carried out by qualified personnel following industry standards and guidelines to ensure accuracy and safety.

- Q: Can stainless steel pipes be used for architectural sculptures?

- Certainly, architectural sculptures can utilize stainless steel pipes. Stainless steel, being a versatile material, provides durability, corrosion resistance, and an elegant appearance. These attributes make it a favored option for sculpting and constructing architectural elements. By manipulating stainless steel pipes, artists and architects can manifest their imaginative concepts in diverse forms and dimensions. Furthermore, the ability of stainless steel to endure extreme weather conditions and its minimal upkeep needs render it appropriate for outdoor installations. In conclusion, when it comes to architectural sculptures, stainless steel pipes present a dependable and aesthetically pleasing choice.

- Q: Are stainless steel pipes suitable for paper mills?

- Yes, stainless steel pipes are suitable for paper mills. Stainless steel is highly resistant to corrosion and can withstand the harsh chemicals and high temperatures typically found in paper mill operations. It is also durable and long-lasting, making it an ideal choice for transporting various fluids and materials within the facility.

- Q: How do stainless steel pipes compare to PEX pipes?

- Stainless steel pipes and PEX pipes have different characteristics and applications. Stainless steel pipes are known for their strength, durability, and resistance to corrosion, making them ideal for high-pressure and high-temperature applications. They are commonly used in industrial settings and for water supply systems. On the other hand, PEX pipes are flexible, lightweight, and easy to install, making them suitable for residential plumbing systems. PEX pipes have good resistance to freezing and are less prone to leaks compared to other materials. Ultimately, the choice between stainless steel and PEX pipes depends on the specific needs and requirements of the project.

Send your message to us

Stainless steel pipe 316Ti 3

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords