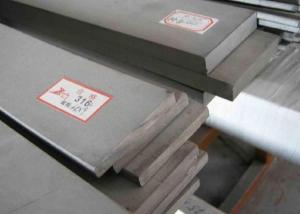

Stainless Steel Flats 316L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q: Can stainless steel pipes be buried in soil?

- Yes, stainless steel pipes can be buried in soil. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions of being buried underground, making it a suitable choice for various underground applications such as drainage, sewage, and water supply systems.

- Q: Can stainless steel pipes be passivated?

- Yes, stainless steel pipes can be passivated. Passivation is a process that removes contaminants from the surface of stainless steel and forms a protective oxide layer, enhancing its corrosion resistance. This process is commonly used in various industries to ensure the long-term durability and performance of stainless steel pipes.

- Q: What is the difference between 304H and 316H stainless steel pipes?

- The main difference between 304H and 316H stainless steel pipes lies in their chemical composition and the elements they contain. 304H stainless steel is a variation of the 304 stainless steel alloy, specifically designed for high-temperature applications. It contains a higher carbon content than standard 304 stainless steel, which enhances its high-temperature strength and resistance to corrosion. This makes it suitable for use in environments where elevated temperatures and corrosive substances are present. On the other hand, 316H stainless steel is a variation of the 316 stainless steel alloy, also designed for high-temperature applications. It contains a higher carbon content than standard 316 stainless steel, similar to 304H, which improves its high-temperature strength. However, 316H stainless steel also contains molybdenum, which provides additional resistance to corrosion, specifically in environments with chlorides, such as seawater or marine applications. In summary, while both 304H and 316H stainless steel pipes are suitable for high-temperature applications, 316H offers better corrosion resistance due to the addition of molybdenum. The choice between the two depends on the specific requirements of the application, such as the presence of corrosive substances or chlorides in the environment.

- Q: What is the difference between seamless and HFW stainless steel pipes?

- Seamless stainless steel pipes are made by piercing a solid billet of stainless steel and then rolling it into a pipe shape without any welding or joints. This seamless manufacturing process results in a smooth and continuous pipe with uniform thickness throughout. On the other hand, HFW (High-Frequency Welding) stainless steel pipes are created by forming a flat strip of stainless steel into a pipe shape and then welding the edges using high-frequency electric currents. This welding process produces a strong and durable joint, but there may be a noticeable weld bead or seam along the length of the pipe. In summary, the main difference between seamless and HFW stainless steel pipes lies in their manufacturing processes. Seamless pipes have no welds or joints, offering a smooth appearance and enhanced corrosion resistance. HFW pipes, although having welded seams, provide a cost-effective option with reliable strength and durability. Ultimately, the choice between these two types of pipes depends on specific application requirements and budget considerations.

- Q: What is the difference between electropolished and mechanically polished stainless steel pipes?

- The main difference between electropolished and mechanically polished stainless steel pipes lies in the method used to achieve the desired surface finish. Electropolishing involves immersing the pipe in an electrolyte solution and applying an electric current, which removes a thin layer of metal and impurities, resulting in a smooth, clean, and corrosion-resistant surface. On the other hand, mechanical polishing involves abrasive materials, such as sandpaper or polishing wheels, to physically remove imperfections and create a smooth surface. Both methods can enhance the aesthetics and performance of stainless steel pipes, but electropolishing offers superior cleanliness, corrosion resistance, and a more uniform finish.

- Q: Are stainless steel pipes resistant to intergranular corrosion?

- Yes, stainless steel pipes are resistant to intergranular corrosion. Stainless steel contains a high amount of chromium, which forms a passive oxide layer on the surface of the metal. This oxide layer acts as a protective barrier, preventing the penetration of corrosive agents and inhibiting the occurrence of intergranular corrosion. Additionally, stainless steel pipes are often alloyed with elements such as molybdenum or titanium, which further enhance their resistance to intergranular corrosion. However, it is important to note that the resistance to intergranular corrosion may vary depending on the specific grade of stainless steel and the environmental conditions in which the pipes are exposed.

- Q: Are stainless steel pipes more expensive than other types of pipes?

- Yes, stainless steel pipes are generally more expensive than other types of pipes. This is mainly due to the high cost of the raw materials used in the production of stainless steel, as well as the complex manufacturing processes involved. Stainless steel pipes also offer a range of advantages over other types of pipes, such as excellent resistance to corrosion, high durability, and the ability to withstand extreme temperatures. These factors contribute to their higher price point. However, the long-term benefits and superior performance of stainless steel pipes often justify the additional cost for many applications.

- Q: Can stainless steel pipes be used for oil and gas applications?

- Yes, stainless steel pipes can be used for oil and gas applications. Stainless steel possesses excellent corrosion resistance properties, making it suitable for handling corrosive fluids such as oil and gas. It also has high strength and durability, making it a reliable choice for these applications. Additionally, stainless steel pipes can withstand high temperatures and pressures, making them well-suited for oil and gas transportation and processing.

- Q: What is the difference between 2205 and 316L stainless steel pipes?

- The main difference between 2205 and 316L stainless steel pipes lies in their chemical composition and their intended applications. 2205 stainless steel is a duplex stainless steel, meaning it is composed of two phases - austenite and ferrite. This composition gives it excellent corrosion resistance, especially in environments with high chloride content. 2205 stainless steel pipes are commonly used in industries such as oil and gas, chemical processing, and marine applications, where resistance to corrosion and high strength are crucial. On the other hand, 316L stainless steel is an austenitic stainless steel with a lower carbon content compared to other grades in the 300 series. It offers good corrosion resistance, especially to acids and chloride solutions, making it suitable for various applications, including food processing, pharmaceuticals, and medical equipment manufacturing. In terms of mechanical properties, 2205 stainless steel pipes generally have higher tensile strength and yield strength compared to 316L stainless steel pipes. This makes 2205 pipes more suitable for applications requiring greater strength and load-bearing capabilities. It is important to note that both grades of stainless steel pipes have their own advantages and limitations. The choice between 2205 and 316L stainless steel pipes depends on the specific application, environmental conditions, and budgetary considerations. Consulting with a materials engineer or a stainless steel expert can help determine the most suitable grade for a particular project.

- Q: What is the difference between satin and brushed finishes in stainless steel pipes?

- Stainless steel pipes can undergo two common types of surface treatments: satin and brushed finishes. These finishes enhance the pipes' appearance and provide some level of corrosion resistance, but they have distinct differences. To achieve a satin finish, a smooth, glossy surface is created using a fine abrasive material. This finish is characterized by its reflective and shiny appearance, similar to satin fabric. It gives the stainless steel pipe a sleek and polished look, making it suitable for applications where aesthetics are important. Satin finishes are commonly used in architectural and decorative applications like handrails, furniture, and kitchen appliances. On the other hand, a brushed finish is achieved by creating a pattern of fine lines on the surface using a wire brush or abrasive pad. This finish has a matte appearance with visible parallel lines running across the surface. Brushed finishes are less reflective than satin finishes and offer a more subdued, industrial look. They are commonly used in applications where durability and resistance to visible wear and tear are important, such as machinery, automotive components, and commercial kitchen equipment. While both satin and brushed finishes provide some level of corrosion resistance, it's worth noting that the surface texture of brushed finishes makes them slightly more resistant to visible scratches and scuffs compared to satin finishes. However, it's important to remember that the overall corrosion resistance of stainless steel is primarily determined by its alloy composition, not the surface finish. In summary, the main difference between satin and brushed finishes in stainless steel pipes lies in their appearance and intended use. Satin finishes offer a reflective and polished look suitable for decorative applications, while brushed finishes provide a more matte and industrial appearance for applications that require durability and resistance to visible wear and tear.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Flats 316L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords