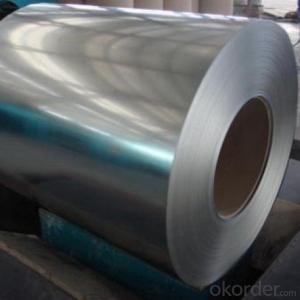

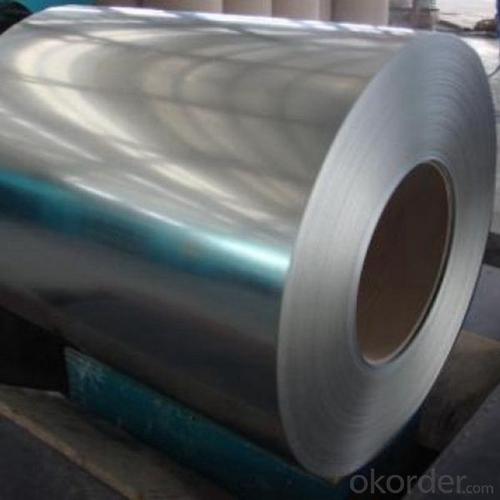

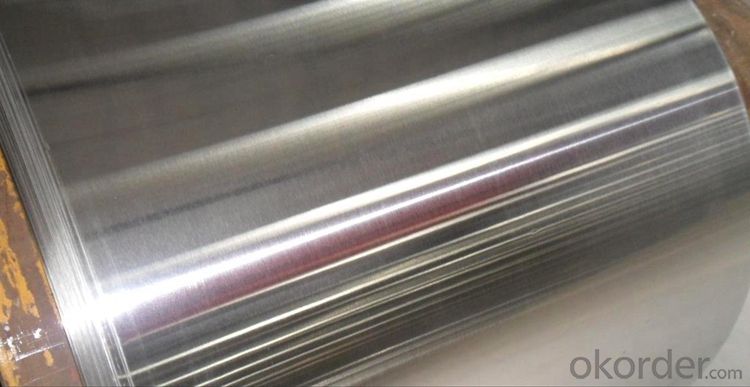

Stainless Steel Coils 304/304L Made In China Cheap Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Type | Stainless Steel Coil /Cold rolled Steel Coils |

Thinckness | 0.23mm-0.8mm |

Diameter | 115mm-560mm |

Quantity | as customer's requirement |

Finish | 2B,BA,HL,MIRROR,NO.1-NO.4,8K,and so on. |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Material | 201,202, 301,304,410,430,409 |

Application range | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | 7-15 days |

Quality | Primary |

Productivity | 3000-4000 tons/month |

Note | We can produce other standard as the customers’ requirement |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Detail picture for Stainless Steel Coils/Sheets

Application of Stainless Steel Coils

(1)Boiler heat exchanger,

(2)Chemical industries,

(3)Hardware fields,

(4)Construction material,

(5)Kitchen utensils,

(6)Building construction,

(7)Medical equipment,

(8)Chemical tank,

(9)Pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: Are stainless steel sheets resistant to humidity?

- Yes, stainless steel sheets are resistant to humidity. Stainless steel is known for its excellent corrosion resistance properties, which includes resistance to moisture and humidity. This makes stainless steel sheets a suitable material for various applications in humid environments such as kitchens, bathrooms, and outdoor structures. The chromium content in stainless steel creates a protective layer of chromium oxide on the surface, which acts as a barrier against moisture, preventing it from penetrating the material and causing corrosion. Additionally, stainless steel sheets are often used in industries like food processing and pharmaceuticals where cleanliness and hygiene are crucial, and their resistance to humidity ensures their durability and longevity in such environments. Overall, stainless steel sheets are a reliable and durable option for humid conditions due to their inherent resistance to moisture and corrosion.

- Q: Are stainless steel sheets suitable for food processing applications?

- Stainless steel sheets excel in food processing applications. Renowned for their exceptional corrosion resistance, stainless steel proves ideal for environments exposed to moisture, chemicals, and food substances. Moreover, its non-porous nature prevents bacterial absorption and contamination, ensuring a hygienic and easily cleaned surface. Additionally, stainless steel sheets' heat resistance allows them to endure high temperatures, rendering them perfect for cooking and processing. Furthermore, their durability and longevity guarantee they can withstand the rigorous demands of food processing operations. Ultimately, the food industry favors stainless steel sheets due to their cleanliness, durability, and corrosion resistance.

- Q: How do I prevent intergranular corrosion on stainless steel sheets?

- To prevent intergranular corrosion on stainless steel sheets, there are several steps that can be taken: 1. Opt for the appropriate stainless steel grade: Choose stainless steel grades that are specifically designed to resist intergranular corrosion, such as 304L, 316L, or 321. These grades have a lower carbon content, which minimizes the formation of chromium carbides at grain boundaries. 2. Apply heat treatment: After fabrication or welding, subject the stainless steel sheets to a solution annealing or post-weld heat treatment process. This treatment eliminates any chromium carbides that may have formed during welding or high-temperature processing, effectively preventing intergranular corrosion. 3. Avoid high temperature exposure: It is crucial to avoid subjecting stainless steel sheets to temperatures between 450 to 850 degrees Celsius (842 to 1562 degrees Fahrenheit) for extended periods. Prolonged exposure to such temperatures can lead to the formation of chromium carbides at the grain boundaries, rendering the stainless steel susceptible to intergranular corrosion. 4. Utilize proper welding techniques: When welding stainless steel sheets, it is important to employ low heat input and minimize the duration of exposure to high temperatures. These measures help reduce the formation of chromium carbides and preserve the corrosion resistance of the stainless steel. 5. Employ pickling and passivation: After fabrication or welding, ensure that the stainless steel sheets undergo thorough pickling and passivation. Pickling removes any surface contaminants, while passivation forms a protective oxide layer that prevents intergranular corrosion. 6. Regularly maintain and clean: To prevent potential corrosion, it is essential to keep the stainless steel sheets clean and free from contaminants. Regularly clean the surfaces using mild detergents and avoid the use of harsh chemicals or abrasive materials that may damage the protective oxide layer. By following these preventative measures, the risk of intergranular corrosion on stainless steel sheets can be significantly reduced, allowing for the preservation of their corrosion resistance properties and an extended lifespan.

- Q: What is the width range available for stainless steel sheets?

- The width range available for stainless steel sheets can vary depending on the supplier, but it typically ranges from 36 inches to 72 inches.

- Q: Do stainless steel sheets require any special handling or storage?

- Yes, stainless steel sheets do require some special handling and storage to maintain their quality and prevent damage. Here are a few key points to consider: 1. Handling: When handling stainless steel sheets, it is important to wear gloves to avoid leaving fingerprints and oils on the surface, which can lead to corrosion. Additionally, sharp tools should be avoided while handling to prevent scratching the surface. 2. Cleaning: Prior to storage, stainless steel sheets should be thoroughly cleaned to remove any dirt, debris, or moisture. This helps to prevent the formation of rust or corrosion during storage. Mild soap or a specialized stainless steel cleaner can be used for cleaning. 3. Storage: Stainless steel sheets should be stored in a clean, dry, and well-ventilated area. They should be kept away from direct sunlight, extreme temperatures, and moisture, as these factors can lead to corrosion. Ideally, they should be stored in a covered area or wrapped in protective materials like plastic or cloth to prevent scratches and damage. 4. Separation: It is important to separate different sheets to avoid contact and potential scratching or damage. This can be achieved by using dividers or interleaf papers between the sheets. 5. Handling equipment: When moving or transporting stainless steel sheets, it is recommended to use appropriate handling equipment like forklifts or cranes. This ensures safe and secure movement without causing any dents or scratches. By following these handling and storage guidelines, stainless steel sheets can be effectively protected and maintained in optimal condition for their intended use.

- Q: Can stainless steel sheets be used for medical implants or devices?

- Yes, stainless steel sheets can be used for medical implants or devices. Stainless steel is a commonly used material in the medical field due to its high strength, corrosion resistance, and biocompatibility. It is particularly suitable for applications such as surgical instruments, orthopedic implants, and dental tools, where durability and hygiene are essential.

- Q: How do I prevent fingerprints or smudges on stainless steel sheets?

- To prevent fingerprints or smudges on stainless steel sheets, there are several easy steps you can follow: 1. Clean the surface regularly: Wiping the stainless steel sheets with a soft cloth or microfiber cloth on a regular basis can help prevent fingerprints and smudges from building up. 2. Use mild soap and water: Mix a few drops of mild dish soap with warm water, and dip the cloth into this solution. Gently wipe the stainless steel surface, following the grain, to remove any dirt or oil that may attract fingerprints. 3. Dry thoroughly: After cleaning, make sure to dry the stainless steel sheets thoroughly using a clean, dry cloth. This will help prevent water spots or streaks that can make the surface appear smudged. 4. Avoid abrasive cleaners or tools: Harsh chemicals, abrasive cleaners, or scrub brushes can damage the stainless steel finish, making it more prone to smudges and fingerprints. Stick to mild cleaning solutions and soft cloths to maintain the integrity of the surface. 5. Apply a stainless steel cleaner or polish: Using a stainless steel cleaner or polish can create a protective barrier on the surface, making it more resistant to fingerprints and smudges. Follow the instructions on the product and apply it with a clean cloth, following the grain of the stainless steel. 6. Use gloves: If you know that your hands tend to leave fingerprints easily, consider wearing gloves while handling stainless steel sheets. This can help prevent direct contact with the surface and minimize the chances of leaving smudges. By following these tips, you can maintain the cleanliness and shine of your stainless steel sheets, preventing fingerprints and smudges from detracting from their appearance.

- Q: Can stainless steel sheets be used for solar panel frames?

- Yes, stainless steel sheets can be used for solar panel frames. Stainless steel is a popular choice for solar panel frames due to its high strength, durability, and corrosion resistance properties. It can withstand various weather conditions, including extreme heat, humidity, and exposure to sunlight. Additionally, stainless steel is non-magnetic and non-combustible, making it a safe choice for solar panel installations. Its high strength-to-weight ratio also allows for lighter frame designs, reducing the overall weight of the solar panels and making them easier to install. Overall, stainless steel sheets are a reliable and long-lasting option for constructing solar panel frames.

- Q: Can stainless steel sheets be used in the aerospace industry?

- Certainly, the aerospace industry can indeed employ stainless steel sheets. With its exceptional mechanical properties, corrosion resistance, and high strength-to-weight ratio, stainless steel is an incredibly versatile material. Hence, it finds great applicability in numerous aerospace uses. For instance, it is frequently utilized in fabricating aircraft elements like engine parts, structural frames, fuel tanks, and exhaust systems. Moreover, stainless steel sheets are also employed in manufacturing aerospace fittings, fasteners, and even interior cabin components. Thanks to its outstanding durability and ability to withstand extreme environments and temperature variations, stainless steel remains a dependable choice for the aerospace industry.

- Q: How do you install stainless steel sheets?

- To install stainless steel sheets, start by measuring and marking the area where you want to install them. Then, use a circular saw or a metal shear to cut the sheets to the desired size. Next, clean the surface where the sheets will be installed and remove any debris or dust. Apply adhesive or a construction-grade adhesive tape to the back of the stainless steel sheet and carefully place it onto the prepared surface, ensuring it is aligned correctly. Use a roller or a block of wood to press the sheet firmly to the wall to ensure proper adhesion. Finally, secure the sheets in place with construction-grade adhesive or stainless steel screws, ensuring they are evenly spaced.

Send your message to us

Stainless Steel Coils 304/304L Made In China Cheap Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords