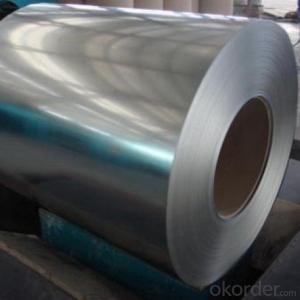

Steel Stainless 304L From China, Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Details for the products:

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Our Service

1.High quanlity and reasonable price.

2.Customized on-demand.

3.Reasonable shipping and fast delivery.

4.Free sample.

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

FAQ for Stainless Steel Coils/Sheets:

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: How do I calculate the strength of stainless steel sheets?

- To calculate the strength of stainless steel sheets, you need to consider several factors such as the material's tensile strength, yield strength, and elongation. Tensile strength refers to the maximum amount of stress a material can withstand before breaking. It is usually measured in pounds per square inch (psi) or megapascals (MPa). To determine the tensile strength of stainless steel sheets, you can refer to the material's specification sheet provided by the manufacturer or consult engineering handbooks. Yield strength, on the other hand, represents the stress at which a material begins to deform permanently. It is an important parameter to consider when designing structures or selecting materials. The yield strength of stainless steel sheets can also be found in the material's specification sheet or engineering references. Elongation, commonly expressed as a percentage, indicates the extent to which a material can stretch or deform before breaking. Higher elongation values suggest greater ductility. The elongation of stainless steel sheets can be determined through tensile testing or obtained from material specifications. These three parameters - tensile strength, yield strength, and elongation - provide insight into the overall strength and performance of stainless steel sheets. It is essential to consider these factors when evaluating the suitability of stainless steel sheets for specific applications or designing structures that require a particular strength level.

- Q: Can stainless steel sheets be etched or engraved?

- Yes, stainless steel sheets can be etched or engraved. Etching and engraving are common methods used to create designs, patterns, and text on stainless steel surfaces. These techniques involve removing a thin layer of the metal to create the desired design. Etching can be done using chemicals or by using a laser, while engraving is typically done using a mechanical tool or laser. The etching or engraving process can create intricate and detailed designs on the stainless steel sheets, making them suitable for a wide range of applications such as signage, decorative panels, nameplates, and more.

- Q: What are the different types of stainless steel sheet patterns available?

- There are several different types of stainless steel sheet patterns available, including plain, diamond, quilted, and hammered. Plain patterns have a smooth, flat surface, while diamond patterns feature raised diamond-shaped ridges. Quilted patterns have a decorative quilt-like design, and hammered patterns have a textured, hammered appearance. These various patterns offer different aesthetic options for stainless steel sheets.

- Q: What is the difference between stainless steel sheets and stainless steel plates?

- Stainless steel sheets and stainless steel plates are both commonly used in various industries and have similar properties, but they differ in terms of thickness and application. Stainless steel sheets are generally thinner than stainless steel plates. They are typically less than 6mm thick and are often used for decorative purposes, such as in kitchen appliances, automotive trim, and signage. Stainless steel sheets can also be easily bent or formed into different shapes, making them suitable for projects that require flexibility. On the other hand, stainless steel plates are thicker and more robust than sheets. They are typically more than 6mm thick and are commonly used in heavy-duty applications, such as construction, machinery, and industrial equipment. Stainless steel plates provide greater strength, durability, and resistance to corrosion, making them suitable for withstanding high temperatures, pressure, and mechanical stress. Another difference lies in the manufacturing process. Stainless steel sheets are usually produced by cold rolling or hot rolling, resulting in a smooth and flat surface. Stainless steel plates, on the other hand, are typically produced through hot rolling followed by heat treatment, which enhances their mechanical properties. In summary, while stainless steel sheets and stainless steel plates are both made of the same material, their thickness, application, and manufacturing process set them apart. Sheets are thinner and more flexible, primarily used for decorative purposes. Plates are thicker, stronger, and designed for heavy-duty applications that require greater strength and durability.

- Q: What's the difference between cold rolling and hot rolling of stainless steel plate?

- Hot rolling is relative to cold rolling, cold rolling is performed under recrystallization temperature, while hot rolling is rolling above recrystallization temperature.

- Q: Are stainless steel sheets suitable for elevator floor panels?

- Yes, stainless steel sheets are suitable for elevator floor panels. Stainless steel is a strong and durable material that is resistant to corrosion, making it a suitable choice for high-traffic areas like elevator floors. It is also easy to clean and maintain, making it ideal for public spaces. Additionally, stainless steel sheets can be customized in terms of size, shape, and finish to meet specific design requirements and aesthetic preferences. Overall, stainless steel sheets offer a combination of durability, aesthetic appeal, and ease of maintenance that make them well-suited for elevator floor panels.

- Q: What are the different types of stainless steel sheet embossing patterns available?

- There are various types of stainless steel sheet embossing patterns available, including diamond, linen, quilted, hammered, and checker plate.

- Q: What are the different types of stainless steel sheet alloys?

- There are several different types of stainless steel sheet alloys, each with their own unique properties and characteristics. Some of the most common types include: 1. Austenitic stainless steel: This is the most widely used type of stainless steel sheet alloy. It is known for its high corrosion resistance and excellent formability. Austenitic stainless steel grades include 304 and 316, which are commonly used in various industries such as food processing, pharmaceuticals, and architecture. 2. Ferritic stainless steel: This type of stainless steel sheet alloy has a higher carbon content and lower chromium content compared to austenitic stainless steel. Ferritic stainless steel is known for its good corrosion resistance and high strength. It is often used in applications where high temperature resistance is required, such as automotive exhaust systems. 3. Martensitic stainless steel: Martensitic stainless steel sheet alloys have a higher carbon content and lower chromium content compared to both austenitic and ferritic stainless steels. They are known for their high strength and hardness, as well as their good corrosion resistance. Martensitic stainless steel grades are commonly used in applications such as cutlery, surgical instruments, and turbine blades. 4. Duplex stainless steel: This type of stainless steel sheet alloy is a combination of austenitic and ferritic stainless steels. It offers a good balance of strength and corrosion resistance, making it suitable for a wide range of applications. Duplex stainless steel grades are commonly used in the chemical processing, oil and gas, and marine industries. 5. Precipitation-hardening stainless steel: This type of stainless steel sheet alloy is heat treatable and can achieve high strength and hardness through a precipitation-hardening process. Precipitation-hardening stainless steel is commonly used in aerospace and defense applications, where high strength and corrosion resistance are critical. These are just a few examples of the different types of stainless steel sheet alloys available. The choice of alloy depends on the specific application requirements, such as corrosion resistance, strength, and temperature resistance.

- Q: Can stainless steel sheets be used in medical equipment?

- Yes, stainless steel sheets can be used in medical equipment. Stainless steel is a popular choice for medical devices and equipment due to its excellent properties such as corrosion resistance, durability, and ease of cleaning. It is commonly used in surgical instruments, implants, hospital equipment, and laboratory tools. Stainless steel sheets are often used in the fabrication of medical equipment due to their versatility and ability to be molded into various shapes and sizes. Additionally, stainless steel is highly biocompatible, meaning it does not react with bodily tissues and is safe for use in medical applications. Overall, stainless steel sheets are a reliable and widely accepted material for medical equipment due to their hygienic properties and long-lasting performance.

- Q: Are stainless steel sheets suitable for high-traffic areas?

- Yes, stainless steel sheets are suitable for high-traffic areas. Stainless steel is known for its durability, strength, and resistance to corrosion, making it an excellent choice for areas that experience heavy foot traffic. It can withstand constant use and abuse, including scratches, dents, and impact, without compromising its structural integrity. Additionally, stainless steel sheets are easy to clean and maintain, making them ideal for areas that require frequent cleaning and disinfection. Overall, stainless steel sheets are a reliable and long-lasting option for high-traffic areas.

Send your message to us

Steel Stainless 304L From China, Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords