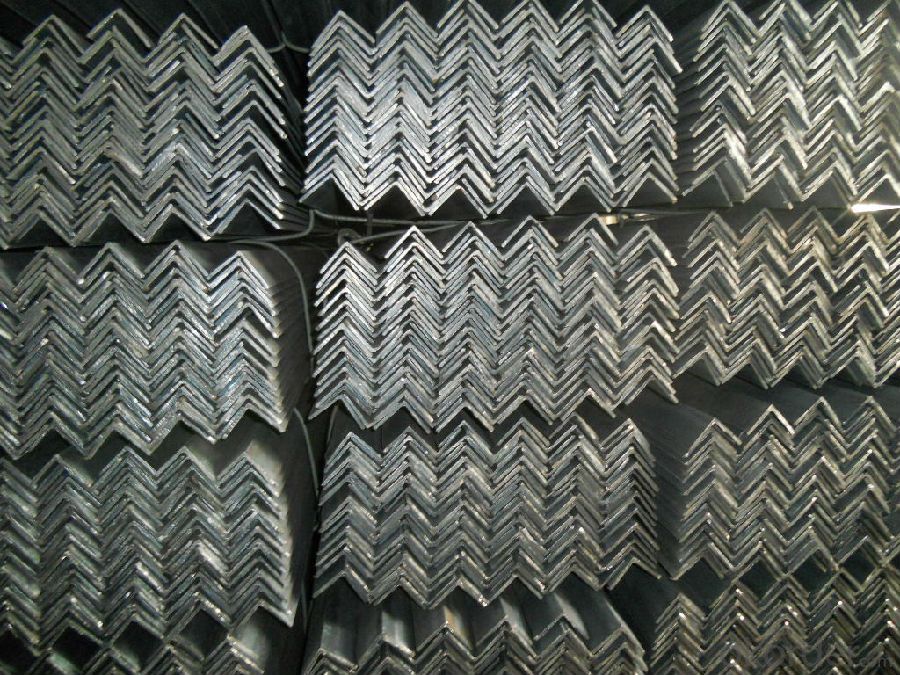

Stainless Steel Angles with High Quatity Grade: SS200,300,400 Series

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Angle Steel Description

Angle steel has equal angle, unequal angle. Standards: GB,ASTM,BS,AISI,DIN,JIS Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400; SS540.

Grade: SS200,300,400 series

Size: 25×25×3 mm-100×100×10mm

Process: HRAP

Length: 2-6m

Shape: Equal

Delivery: within 20 days

MOQ: 1 ton

Certificate: ISO 9001:2008, SGS

Package:Standard Export Packing, or put into wooden boxes according to your requirement

Application: Construction, Marine, Industry and so on

Name | Stainless Steel Angles | ||||||

Standard | ASTM A554, A312, A249, A269 and A270 | ||||||

Material Grade | 304,316,201,202, 316L,430 | ||||||

Length | 6m or as customers' request | ||||||

Tolerance | a) thickness: +/-0. 15mm | ||||||

b) Length:+/-4. 5mm - 0mm | |||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

Application | Decoration construction, upholstery, industry instruments | ||||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

Chemical Composition of Material | Composition Material | 201 | 202 | 304 | 316L | 430 | |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | ||

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ||

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | ||

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | ||

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | ||

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | ||

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | |||

Mo | 2.0-3.0 | ||||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316L | ||

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | |||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | |||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | |||

Hardness (HV) | <253< p=""> | <253< p=""> | <200< p=""> | <200< p=""> | |||

2.Main Features of angle steel

Broad-spectrum

High quantity

High strength

3.Usage & Applications of High Quatity Grade: SS200,300,400 Series Stainless Steel Angles

Trusses

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

4.Packaging & Delivery of GB Q235 Angle Steel

Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

- Q: What are the different types of connections used for steel angles?

- Steel angles can be connected in several ways, depending on the application and load requirements. Here are some commonly used connections: 1. Welded Connection: The most frequently used connection for steel angles involves welding them to other members, such as beams or columns. These connections offer high strength and stiffness, making them suitable for heavy loads and structural purposes. 2. Bolted Connection: Another option is to bolt the steel angles to the connected members using bolts and nuts. Bolted connections are preferred when the structure may need to be disassembled or relocated. They offer flexibility, adjustability, and easy installation. 3. Riveted Connection: While not as commonly used nowadays, riveted connections were widely employed in older structures. Riveting involves joining the steel angle to other members using rivets. Although they require skilled labor for installation, riveted connections provide good strength and durability. 4. Clip Connection: A clip connection is a type of bolted connection where a clip or bracket is used to secure the steel angle to the supporting member. This allows for easy assembly and disassembly, making it suitable for temporary structures or situations requiring frequent modifications. 5. Shear Connection: Shear connections use shear plates or angles to connect the steel angle to the supporting member. These connections primarily transfer shear forces and provide sufficient strength and rigidity. 6. Cleat Connection: Cleat connections involve using a cleat plate, typically welded or bolted, to connect the steel angle to the supporting member. Cleat connections are commonly employed in industrial applications where heavy loads and high forces need to be transferred. When selecting the appropriate type of connection for steel angles, it is crucial to consider the specific requirements of the structure, including load capacity, design codes, and environmental conditions. Consulting with a structural engineer or referring to relevant design standards can ensure the proper selection and installation of the connection.

- Q: What are the different methods of surface painting for steel angles?

- There exists a variety of techniques for surface painting steel angles, each offering distinct advantages and considerations. 1. Brushing: The most commonly employed method for surface painting steel angles involves the manual application of paint using a brush. Brushing provides excellent control and precision, making it well-suited for smaller projects or touch-ups. However, it may not be as efficient for larger-scale applications. 2. Spraying: When a large area needs to be painted quickly, spraying is a popular technique for painting steel angles. It involves the even distribution of paint onto the surface using a paint spray gun or aerosol canister. Spraying results in a smooth and uniform finish, but proper safety precautions, such as wearing a mask and ensuring adequate ventilation, are necessary. 3. Dipping: In this method, steel angles are immersed in a tank or container filled with paint. Dipping ensures complete coverage and is often utilized in high-volume production processes. However, it may not be suitable for angles with intricate designs or complex shapes, as excess paint may drip or accumulate unevenly. 4. Electrostatic painting: Electrostatic painting involves charging the paint particles and applying them to a grounded steel angle. This creates an electromagnetic attraction, resulting in an even and efficient coverage. This technique is commonly employed in industrial settings and aids in reducing paint waste and overspray. 5. Powder coating: Powder coating is a dry finishing process that entails the application of a fine powder onto the surface of a steel angle. The powder is then heated and fused onto the metal, creating a durable and visually appealing finish. Powder coating offers excellent corrosion resistance and can be done in a variety of colors and textures. However, specialized equipment is required, and it may not be suitable for small-scale or on-site applications. When selecting a surface painting method for steel angles, careful consideration must be given to factors such as project size and complexity, desired finish quality, environmental conditions, and available resources. Seeking guidance from a professional painter or coating specialist can help determine the most appropriate method for a specific application.

- Q: What are the limitations of using steel angles in corrosive or saltwater environments?

- The use of steel angles in corrosive or saltwater environments is limited due to their susceptibility to corrosion. Steel is primarily composed of iron, which can react with oxygen and water to form iron oxide, commonly known as rust. In the presence of corrosive substances or saltwater, this corrosion process is accelerated. One limitation is the potential for accelerated corrosion in these environments. Corrosion weakens the structural integrity of the steel angles, which can compromise the overall stability and safety of any structure they are used in. This can be particularly concerning in applications where the steel angles are load-bearing or subjected to significant stress. Another limitation is the decrease in the lifespan of steel angles in corrosive or saltwater environments. The ongoing corrosion process can significantly reduce the lifespan of the steel angles, leading to more frequent maintenance or replacement requirements. This can result in higher costs and potential disruptions to operations or projects. Furthermore, the appearance of the steel angles can be negatively affected by corrosion in corrosive or saltwater environments. Rust stains can develop on the surface of the steel, which can be aesthetically unappealing, especially in applications where the steel angles are visible. To overcome these limitations, alternative materials can be considered for corrosive or saltwater environments. Stainless steel, for example, contains a high proportion of chromium, which provides it with enhanced corrosion resistance. Additionally, protective coatings or treatments, such as galvanizing or epoxy coatings, can be applied to steel angles to provide an additional barrier against corrosion. Overall, while steel angles are versatile and widely used in various applications, their use in corrosive or saltwater environments is limited due to their susceptibility to corrosion. It is crucial to carefully evaluate the specific environment and consider alternative materials or protective measures to ensure the longevity and integrity of any structure or project.

- Q: Can steel angles be used for electrical conduits?

- No, steel angles cannot be used for electrical conduits as they are not designed or suitable for carrying electrical wiring. Electrical conduits are typically made of materials such as PVC, steel, or aluminum that are specifically designed to safely enclose and protect electrical wires.

- Q: Can steel angles be used for machinery frames?

- Yes, steel angles can be used for machinery frames. Steel angles are commonly used in construction and manufacturing industries due to their strength and versatility. They are often used to provide structural support and stability in various applications, including machinery frames. Steel angles offer a cost-effective solution as they are readily available and can be easily fabricated to meet specific design requirements. Additionally, steel angles provide excellent load-bearing capacity and resistance to deformation, making them suitable for supporting heavy machinery and equipment. Their rigid and durable nature ensures the stability and longevity of machinery frames, making them a reliable choice in industrial settings.

- Q: What are the maintenance requirements for steel angles?

- The maintenance requirements for steel angles typically involve regular cleaning and inspection for signs of corrosion or damage. It is important to remove any dirt or debris that may accumulate on the surface of the steel angles, as they can potentially lead to corrosion. Additionally, it is advisable to apply a protective coating or paint to prevent rusting. Routine inspections should be conducted to identify any signs of wear or structural issues that may require repairs or replacements.

- Q: How do you determine the required number of fasteners for a steel angle connection?

- To determine the required number of fasteners for a steel angle connection, several factors need to be considered. These include the load being applied, the size and thickness of the angle, the type and strength of the fasteners being used, and any applicable building codes or engineering standards. Typically, calculations or guidelines provided by structural engineers or industry standards are used to determine the minimum number and spacing of fasteners needed to ensure the connection is strong and safe.

- Q: How do steel angles perform in terms of durability and longevity?

- Steel angles are renowned for their exceptional durability and longevity. Due to their composition, which includes a high percentage of iron and carbon, steel angles possess remarkable strength and resistance to various forms of wear and tear. They can withstand heavy loads, extreme temperatures, and exposure to corrosive elements, making them highly durable in a wide range of applications. In terms of longevity, steel angles have an impressive lifespan. They are designed to withstand the test of time and retain their structural integrity over extended periods. The inherent strength and resilience of steel angles ensure that they do not degrade easily, making them a reliable choice for long-term use. Furthermore, steel angles require minimal maintenance to preserve their durability and longevity. Regular inspections and cleaning can help prevent the buildup of rust and other forms of corrosion, ensuring that the angles remain in optimal condition throughout their lifespan. Moreover, steel angles can be galvanized or coated with protective layers to enhance their durability and resistance to environmental factors. Galvanization involves applying a layer of zinc to the steel surface, providing an additional barrier against rust and corrosion. Coatings such as epoxy or powder coatings can also be applied to further enhance the durability and longevity of steel angles in specific environments. Overall, steel angles are known for their exceptional durability and longevity. They offer a reliable and long-lasting solution for a variety of structural and construction needs, making them a popular choice in many industries.

- Q: How do steel angles perform in saltwater environments?

- Steel angles perform well in saltwater environments due to their high corrosion resistance. The addition of alloying elements, such as chromium and nickel, in the steel composition enhances its resistance to corrosion caused by saltwater exposure. These alloying elements create a protective oxide layer on the surface of the steel, preventing direct contact between the steel and the corrosive saltwater. Additionally, steel angles can be further protected with coatings or galvanization, which provide an additional barrier against saltwater corrosion. Overall, steel angles are a durable and reliable choice for applications in saltwater environments, as they can withstand the harsh conditions and maintain their structural integrity over time.

- Q: What are the different types of steel angles used in automotive engineering?

- There are several types of steel angles used in automotive engineering, including equal angles, unequal angles, and L-shaped angles. These angles are commonly used for structural support, reinforcement, and to provide strength and stability to various components of the vehicle.

Send your message to us

Stainless Steel Angles with High Quatity Grade: SS200,300,400 Series

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords