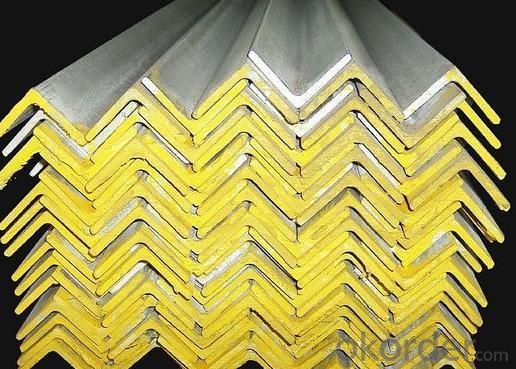

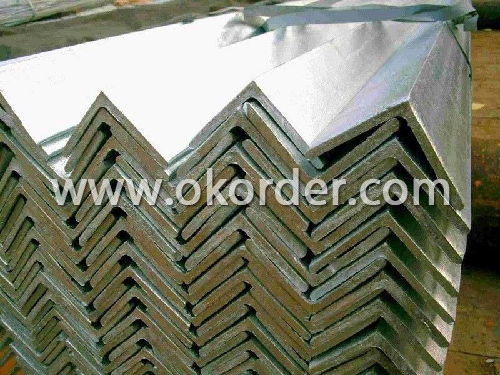

Best Quality for 304 Equal Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Angles

General Information of Stainless Steel Angles

1. Grade: SS200, 300,400 series

2. Size: 25×25×3 mm-100×100×10mm

3. Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package: Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry and so on

Specification of Stainless Steel Angles

Name | Stainless Steel Angles | |||||

Standard | ASTM A554, A312, A249, A269 and A270 | |||||

Material Grade | 304,316,201,202, 316L,430 | |||||

Length | 6m or as customers' request | |||||

Tolerance | a) Thickness: +/-0. 15mm | |||||

b) Length: +/-4. 5mm - 0mm | ||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | |||||

Application | Decoration construction, upholstery, industry instruments | |||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | |||||

Chemical Composition of Material | Composition Material | 201 | 202 | 304 | 316L | 430 |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | |

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | |

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | |

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | |

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | |

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | |

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | ||

Mo | 2.0-3.0 | |||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316L | |

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | ||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | ||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | ||

Hardness (HV) | <253 | <253 | <200 | <200 | ||

- Q: How does stainless steel angle perform in high-pressure applications?

- Stainless steel angle performs exceptionally well in high-pressure applications due to its inherent strength, corrosion resistance, and durability. Its unique composition and structural integrity allow it to withstand extreme pressures without deformation or failure, making it a reliable choice for various industries such as oil and gas, chemical processing, and aerospace.

- Q: Can stainless steel angle be used in agricultural machinery?

- Yes, stainless steel angle can be used in agricultural machinery. Stainless steel is known for its durability, corrosion resistance, and strength, making it suitable for various applications in the agricultural industry. Stainless steel angles can be used in the construction of frames, supports, and brackets for agricultural machinery such as tractors, harvesters, and irrigation systems. They provide structural integrity and stability, even in harsh environments, and can withstand exposure to moisture, chemicals, and other corrosive elements commonly found in agricultural settings. Additionally, stainless steel angles can be easily fabricated and welded to meet specific design requirements, making them a versatile choice for agricultural machinery components.

- Q: How do you calculate the shear stress of a slotted stainless steel angle?

- In order to determine the shear stress of a slotted stainless steel angle, various factors need to be taken into account. The first step is to ascertain the shear force exerted on the angle. This can be achieved by analyzing the load or force applied to the angle. Subsequently, the shear area of the slotted stainless steel angle must be calculated. The shear area refers to the section of the angle's cross-sectional area that will be subjected to the shear force. For a slotted angle, this can be determined by considering the width and thickness of the angle at the location of the slot. Once the shear force and shear area are known, the shear stress can be calculated using the following formula: Shear Stress = Shear Force / Shear Area It is crucial to employ consistent units for both the shear force and shear area to guarantee precise results. Additionally, any relevant safety factors or design codes that may impact the calculation should be taken into consideration.

- Q: What is the thermal conductivity of stainless steel angles?

- The thermal conductivity of stainless steel angles typically ranges from 15 to 45 W/m·K, depending on the specific grade and composition of the stainless steel used.

- Q: Can stainless steel angles be used for scaffolding?

- Yes, stainless steel angles can be used for scaffolding. Stainless steel is known for its durability, corrosion resistance, and strength, making it suitable for constructing scaffolding structures that require stability and safety in various environments.

- Q: What are the different types of stainless steel angles profiles?

- There are several different types of stainless steel angle profiles available, each with their own unique characteristics and applications. Some of the most common types include: 1. Equal Leg Angle: This type of stainless steel angle has equal dimensions on both legs, making it ideal for applications where symmetry is important. It is commonly used in structural applications, such as construction and fabrication projects. 2. Unequal Leg Angle: As the name suggests, this type of stainless steel angle has unequal dimensions on its legs. It is often used in applications where one leg needs to be longer or shorter than the other, such as framing or bracing. 3. L-Shaped Angle: This profile features a 90-degree angle, forming an L-shape. It is commonly used in corners or as a support for shelves, cabinets, or countertops. 4. Rounded Edge Angle: This type of stainless steel angle has rounded edges instead of sharp corners. It is often used in applications where safety is a concern, such as playground equipment or handrails. 5. Slotted Angle: Slotted stainless steel angles have holes or slots along their length, allowing for easy attachment and adjustment. They are frequently used in shelving systems, racks, or framework where flexibility and adjustability are crucial. 6. Decorative Angle: These angles are designed to enhance the aesthetic appeal of a space. They come in various patterns and finishes, making them suitable for architectural or interior design purposes. It's worth noting that these are just a few examples of the many stainless steel angle profiles available. The specific type of angle profile chosen depends on the intended use, load-bearing requirements, and aesthetic preferences of the project.

- Q: How do you calculate the moment of resistance for a rounded corner stainless steel angle?

- To calculate the moment of resistance for a rounded corner stainless steel angle, you need to consider the cross-sectional area and the material properties of the angle. The moment of resistance is a measure of the ability of the angle to resist bending or twisting forces applied to it. First, determine the cross-sectional area of the angle. For a rounded corner stainless steel angle, the cross-sectional shape will be a combination of straight sides and rounded corners. Measure the width and thickness of the angle, and then subtract the area of the rounded corners. This can be done by calculating the area of the full square or rectangular shape and subtracting the area of the rounded corners using appropriate formulas or measurements. Once you have the cross-sectional area, you need to determine the material properties of the stainless steel angle. This includes the yield strength and the modulus of elasticity. The yield strength is the maximum stress the angle can withstand before it deforms permanently, while the modulus of elasticity is a measure of the stiffness of the material. Next, use the following formula to calculate the moment of resistance: Moment of Resistance = Yield Strength × Cross-sectional Area × (Distance from the neutral axis)^2 The distance from the neutral axis is the distance between the center of the cross-sectional area and the extreme fiber of the angle. This can be calculated by dividing the height of the angle by 2 if the angle is symmetric, or by using appropriate geometric calculations for an asymmetric angle. Once you have all the necessary values, plug them into the formula to calculate the moment of resistance. The resulting value will give you an indication of the angle's ability to resist bending or twisting forces. This information is crucial for structural engineering and design applications to ensure the angle can safely support the intended loads.

- Q: What is the difference between 304LN and 316LN stainless steel angles?

- The main difference between 304LN and 316LN stainless steel angles is the chemical composition and their respective corrosion resistance properties. 304LN stainless steel angles have a higher content of chromium and nickel, which provides good resistance to corrosion and oxidation in various environments. However, they may be more susceptible to chloride-induced stress corrosion cracking compared to 316LN stainless steel angles. On the other hand, 316LN stainless steel angles contain molybdenum in addition to chromium and nickel, which enhances their resistance to pitting and crevice corrosion, especially in chloride-containing environments. They are commonly used in marine and coastal applications where exposure to saltwater or other corrosive substances is frequent. In summary, while both 304LN and 316LN stainless steel angles offer good corrosion resistance, 316LN stainless steel angles provide superior protection against pitting and crevice corrosion in more aggressive environments.

- Q: Can stainless steel angles be used in architectural facades?

- Architectural facades can indeed incorporate stainless steel angles. This material is highly versatile, offering durability, resistance to corrosion, and an attractive appearance, making it well-suited for a variety of architectural uses. By utilizing stainless steel angles, one can achieve clean and sharp lines in the design of these facades, resulting in a sleek and modern look. Moreover, stainless steel is available in different finishes, such as brushed or polished, allowing for customization to match the desired aesthetic of the building. The strength and stability of stainless steel angles also make them a dependable choice for supporting architectural elements, including cladding panels or decorative features, ensuring the longevity and structural integrity of the facade. In summary, stainless steel angles provide a practical and visually pleasing solution for architectural facades.

- Q: Can stainless steel angles be used for balcony grilles?

- Yes, stainless steel angles can be used for balcony grilles. Stainless steel is a popular choice for balcony grilles due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel angles provide structural support and strength to the grilles, making them suitable for use in balconies. Additionally, stainless steel angles can be easily fabricated and customized to meet specific design requirements for balcony grilles. Overall, stainless steel angles are a reliable and long-lasting option for balcony grilles.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for 304 Equal Stainless Steel Angles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords