Special Steel AISI 6150 SUP10 Spring Flat Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product information:

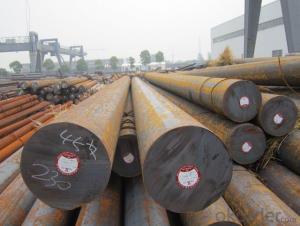

SPRING STEEL

1. Steel grade: SUP7/61SiCr7, SUP9/55Cr3, SUP9A/60Cr3, SUP10/51CrV4 etc

2. Size:

A. Spring steel flat bar: Thickness: 5mm-30mm, Width: 50mm-150mm, Length: 4m-6m |

B. Spring steel round bar: dia: 6mm-250mm |

3. Techniques: hot rolled and heat treatment

4. Surface: plain and grooved

5. Packaging: packing for export standard

6. Delivery terms and time: FOB or CFR or CIF/according to QTY

7. Payment : By 30% T/T in advance and the balance is for irrevocable L/C at sight

8. Advantages: accurate tolerance, large inventories, full-size, fast delivery and good after-sale service

9.Application: automotive suspension springs

Product Show:

Workshop Show:

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: What are the different methods of controlling the grain size in special steel?

- To achieve desired mechanical properties and performance, there are multiple approaches available for controlling the grain size in special steel. The following are some of the techniques that can be employed: 1. Alloying: The grain size in steel can be controlled by carefully selecting and managing the composition of alloying elements. Elements like niobium, vanadium, and titanium have proven effective in refining the grain size. 2. Heat treatment: The grain size can be regulated through the process of heat treatment. Techniques such as annealing, normalizing, and quenching can be utilized to manipulate the grain size. For example, slow cooling during annealing encourages the growth of larger grains, while rapid cooling during quenching leads to smaller grain sizes. 3. Deformation processing: Mechanical deformation methods like rolling, forging, or extrusion can aid in refining the grain structure. These processes induce strain and facilitate the formation of smaller and more uniform grains. 4. Grain growth inhibitors: The addition of specific elements like aluminum or zirconium to the steel can act as inhibitors for grain growth. These elements create fine particles that impede the growth of grains during heat treatment, resulting in a smaller grain size. 5. Control of transformation temperature: Manipulating the transformation temperature during heat treatment allows for control over the grain size. Lowering the austenitizing temperature, for example, can yield a finer grain structure in the final product. 6. Rapid solidification: Employing techniques such as spray forming or rapid quenching can lead to an ultrafine-grained microstructure. The rapid cooling prevents grain growth, resulting in a fine and homogeneous grain structure. 7. Severe plastic deformation (SPD) techniques: Techniques like equal channel angular pressing (ECAP) or high-pressure torsion (HPT) impose significant strain on the material, leading to a refined grain structure. These methods are commonly used for producing ultrafine-grained or nanostructured steels. It is essential to consider the desired properties, alloy composition, and intended application of the final product when choosing a method for controlling the grain size in special steel.

- Q: What are the main advantages of using special steel in the automotive industry?

- Special steel offers several advantages in the automotive industry. Firstly, it provides enhanced strength and durability, ensuring the safety and reliability of vehicles. Secondly, special steel is lightweight, contributing to fuel efficiency and reducing carbon emissions. Additionally, it offers excellent formability and weldability, allowing for complex and intricate designs. Lastly, special steel possesses high corrosion resistance, extending the lifespan of automotive components and reducing maintenance costs. Overall, the use of special steel in the automotive industry enhances performance, efficiency, safety, and longevity.

- Q: What are the environmental impacts of using special steel?

- The environmental impacts of using special steel can vary depending on factors such as the production process, sourcing of raw materials, and waste management practices. However, some common environmental impacts associated with special steel production include carbon dioxide emissions, energy consumption, water pollution, and habitat destruction. Special steel often requires high energy inputs and releases significant amounts of greenhouse gases during production, contributing to climate change. Additionally, the extraction and processing of raw materials used in special steel production can lead to water pollution and habitat degradation if not managed properly. It is important for industries to adopt sustainable practices and technologies to minimize these environmental impacts and promote a more sustainable use of special steel.

- Q: How does special steel contribute to improving product quality?

- Special steel contributes to improving product quality in several ways. Firstly, special steel is known for its superior strength, durability, and resistance to corrosion, making it ideal for manufacturing high-quality products that can withstand challenging conditions and last longer. Secondly, special steel often has unique properties like high heat resistance, excellent machinability, or specific magnetic properties, which enable manufacturers to create products with enhanced performance and functionality. Moreover, special steel allows for precise and intricate designs, enabling the production of complex components with tight tolerances, resulting in improved accuracy and efficiency. Overall, the use of special steel in manufacturing processes helps to ensure that the final products are of higher quality, more reliable, and better suited to meet the needs and expectations of customers.

- Q: What are the different casting grades of special steel?

- The different casting grades of special steel include low alloy steel, high alloy steel, stainless steel, tool steel, and heat-resistant steel.

- Q: What is the process of manufacturing special steel?

- To produce high-quality and durable special steel with specific properties, several steps must be taken in the manufacturing process. Firstly, the raw materials needed for special steel production, such as iron ore, coal, chromium, nickel, and manganese, are selected meticulously based on the desired properties of the final product. Once the raw materials have been chosen, they are melted in large furnaces, either through the use of electric arc furnaces or basic oxygen furnaces. These furnaces subject the raw materials to extremely high temperatures, transforming them into molten metal. After the raw materials have been melted, the molten metal undergoes a refining process to eliminate any impurities. Techniques such as degassing, desulphurization, and deoxidation are employed to ensure that the steel is free from unwanted elements that could have a negative impact on its properties. Next, alloying elements are added to the molten metal after the refining process to achieve the desired properties. The proportion and specific alloying elements utilized depend on the intended application of the special steel. The molten steel is then poured into a continuous casting machine, which solidifies it into semi-finished products known as billets, blooms, or slabs. This continuous casting process guarantees a consistent and uniform structure throughout the steel. The semi-finished products are reheated and passed through a series of hot rolling mills. This process involves reducing the thickness and shaping the steel into various forms, including bars, rods, plates, or sheets, depending on the intended use. Following hot rolling, the steel may undergo heat treatment processes like annealing, quenching, tempering, or case hardening. These treatments further enhance the mechanical properties of the steel, such as its hardness, toughness, and ductility. The final step involves surface finishing and quality control measures. The steel is thoroughly inspected for any defects or imperfections that may have occurred during the manufacturing process. Surface treatments like pickling or galvanizing can also be applied to enhance the steel's appearance and protect it from corrosion. In conclusion, manufacturing special steel is a complex and precise operation that involves careful selection of raw materials, melting, refining, alloying, continuous casting, hot rolling, heat treatment, and finishing. These steps ensure that the resulting steel meets the specific requirements and performance characteristics demanded by various industries.

- Q: Is special steel recyclable?

- Yes, special steel is recyclable.

- Q: How does special steel perform in high-temperature creep conditions?

- Special steel is specifically designed and engineered to perform exceptionally well in high-temperature creep conditions. It exhibits remarkable resistance to deformation and maintains its mechanical properties even at elevated temperatures, making it highly reliable and suitable for applications that require stability and strength in such environments.

- Q: How is special steel used in the production of springs?

- Special steel is used in the production of springs due to its excellent mechanical properties. It provides the necessary strength, durability, and elasticity required for springs to function effectively. The unique composition and heat treatment of special steel enable springs to withstand high levels of stress and repetitive loading, ensuring their longevity and reliability in various applications such as automotive, aerospace, and machinery industries.

- Q: What are the different methods of surface laser cladding for special steel?

- There are several different methods of surface laser cladding that can be used for special steel. One common method is powder-based laser cladding. In this process, a powder material is injected into the laser beam, which melts and fuses with the surface of the special steel. The powder material can be chosen to provide specific properties such as enhanced hardness or corrosion resistance. This method allows for precise control over the thickness and composition of the cladding layer. Another method is wire-based laser cladding. In this process, a wire material is fed into the laser beam, which melts and fuses with the special steel surface. Wire-based laser cladding is often used for larger areas or when a thicker cladding layer is required. It is also commonly used for repairing or salvaging worn or damaged parts. A third method is direct energy deposition (DED) laser cladding. This method involves using a laser beam to melt a powder or wire material as it is being deposited onto the special steel surface. DED laser cladding allows for rapid build-up of multiple layers and is often used for additive manufacturing or repairing high-value components. Each method of surface laser cladding has its own advantages and limitations, and the choice of method depends on factors such as the desired cladding thickness, material properties, and the specific requirements of the application.

Send your message to us

Special Steel AISI 6150 SUP10 Spring Flat Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords