Special Steel 6150 Steel/6150 Steel Round Bar/Tool Steel 6150

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The details of our Steel

1. Produce Standard: as the GB, AISI, ASTM, SAE, EN, BS, DIN, JIS Industry Standard

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment:

Normalized / Annealed / Quenched+Tempered

4. Quality assurance:

All order we can received Third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product information

1.Specification of 6150 steel | |||||||||||||

Round bar | Diameter(mm) | Length (mm) | |||||||||||

10~300 | 2000~5800 | ||||||||||||

Plate | Thickness(mm) | Width (mm) | Length (mm) | ||||||||||

20~70 | 105~610 | 2000~5800 | |||||||||||

The specification can be customised! | |||||||||||||

2.Chemical compositon of 6150 steel | |||||||||||||

NO. | C | Mn | Si | Cr | V | Ni | P | S | |||||

Aisi 6150 steel | 0.5 | 0.7 | 0.3 | 1.00 | 0.15 | ≤0.25 | ≤0.025 | ≤0.025 | |||||

3. Mechanical properties of 6150 steel | |||||||||||||

Tensile str. (N/mm2) | Yield point (N/mm2)

| Elongation (%) | Hardness | ||||||||||

≥1372(140) | ≥1225(125) | ≥5 | ≤321HB | ||||||||||

4.Heat treatment of 6150 steel | |||||||||||||

1. Normalizing: 830 ~ 860C - air cooling - HBS less than 302 | |||||||||||||

2. Annealing: 750C - furnace cooling - HBS less than 222 | |||||||||||||

3. Quenching: 850C oil HRC>61 | |||||||||||||

4. HRC after tempering: 150C 61,200 C - 60,300 C - 56,400 C - 51, 500 C - 43,550 C - 38,600 C - 33,650 C – 29 | |||||||||||||

5.Characteristic of 6150 steel | |||||||||||||

(1) high toughness and strength | |||||||||||||

(2) high hardnenability | |||||||||||||

(3) good antifatigue property | |||||||||||||

(4) excellent mechanical property | |||||||||||||

6.Application of 6150 steel | |||||||||||||

(1) Spring steel for gas engine, car within 200°C | |||||||||||||

(2) hardness after annealing ≤255HBS | |||||||||||||

Main product

High speed steel | |

AISI | M2,M4,M35,M42,T1 |

DIN | 1.3343,1.3243,1.3247,1.3355 |

JIS | SKH51,SKH54,SKH35,SKH59,SKH2 |

Cold work tool steel | |

AISI | D2,D5,D3,D6,A8,A2,O1 |

DIN | 1.2379,1.2601,1.2080,1.2436,1.2631,1.2363,1.2510,1.2327 |

JIS | SKD10,SKD11,SKD1,SKS3 |

Hot work tool steel | |

AISI | H13,H11,H21 |

DIN | 1.2344,1.2343,1.2367,1.2581,1.2713 |

JIS | SKD61,SKD6,SKD7,SKD5SKT4 |

Plastic mould steel | |

AISI | P20,P20+Ni,420 |

DIN | 1.2311,1.2738,1.2083,1.2316 |

JIS | PDS-3,SUS420J1,SUS420J2 |

Alloy structural seel | |

AISI | 5140,4340,4135,4140 |

DIN | 1.7035,1.6511,1.7220,1.7225 |

JIS | SCr440,SNCM439,SCM435,SCM440 |

Stainless steel | |

AISI | 440C,420,430 |

DIN | 1.4125 |

JIS | SUS440C |

Carbon steel | |

AISI | 1045,1020 |

DIN | 1.1191 |

JIS | S45C, G3101 |

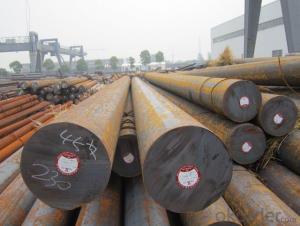

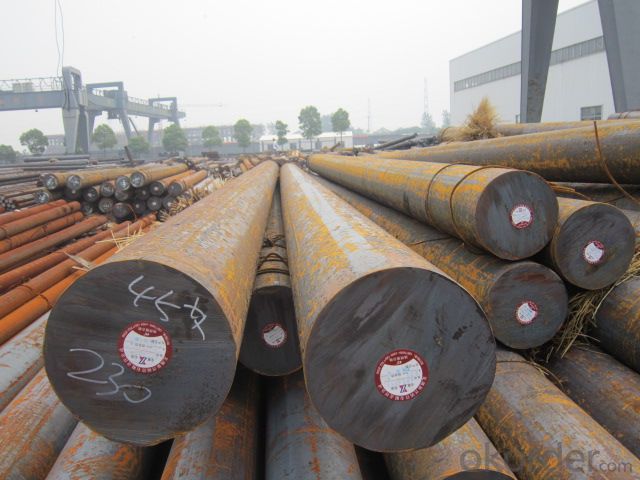

Product show

Workshop show

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: How does special steel perform in high-speed machining operations?

- Special steel is specifically designed to withstand high-speed machining operations with exceptional performance. Its unique composition and properties, including high hardness, heat resistance, and wear resistance, allow it to maintain its strength and durability even under extreme cutting speeds and temperatures. This enables special steel to deliver superior machining efficiency, precision, and surface finish, making it an ideal choice for high-speed machining operations.

- Q: How does special steel perform in cryogenic creep resistance?

- Special steel is known for its exceptional performance in cryogenic creep resistance. Cryogenic creep refers to the deformation that occurs in materials under constant stress at extremely low temperatures. Special steel, due to its unique composition and manufacturing processes, exhibits superior resistance to this type of deformation compared to other materials. The low temperature environment encountered in cryogenic applications can cause conventional materials to lose their strength and become more susceptible to creep deformation. However, special steel is specifically designed to withstand these challenging conditions. Its composition typically includes a higher proportion of alloying elements such as nickel, chromium, and molybdenum, which enhance its mechanical properties and improve its resistance to creep at cryogenic temperatures. Furthermore, special steel undergoes rigorous heat treatment and processing techniques to optimize its microstructure and strengthen its grain boundaries. This results in a material with improved strength, toughness, and resistance to creep deformation, even at extremely low temperatures. The exceptional performance of special steel in cryogenic creep resistance makes it highly suitable for applications that involve storage, transportation, or processing of materials at cryogenic temperatures. Industries such as aerospace, energy, and scientific research heavily rely on special steel for the construction of cryogenic storage tanks, superconducting magnets, and cryogenic valves, among others. In conclusion, special steel exhibits remarkable performance in cryogenic creep resistance due to its unique composition, heat treatment, and processing techniques. Its ability to maintain its mechanical properties and resist deformation at extremely low temperatures makes it an ideal choice for various cryogenic applications.

- Q: What are the requirements for special steel used in high-performance racing cars?

- In order to meet the demands of the racing environment, the requirements for special steel used in high-performance racing cars are quite strict. Some of the main requirements include: 1. Exceptional strength and durability: The special steel must possess outstanding strength and durability to endure the extreme loads and stresses encountered during high-speed racing. It must have a high tensile strength and the ability to withstand fatigue and deformation under intense conditions. 2. Lightweight: Racing cars require lightweight materials to achieve optimal performance and maneuverability on the track. The special steel used in high-performance racing cars must have a high strength-to-weight ratio, allowing for reduced weight without compromising strength or safety. 3. Excellent heat resistance: The steel must have excellent heat resistance to withstand the high temperatures generated by high-performance engines, braking systems, and exhaust systems. It must maintain its structural integrity and mechanical properties even under extreme heat conditions. 4. High corrosion resistance: Racing cars are often exposed to harsh environments, including moisture, salt, and other corrosive elements. Therefore, the special steel used in racing cars should have high corrosion resistance to prevent rust and degradation, ensuring the longevity and reliability of the components. 5. Easy machinability: The steel should be easily machinable, facilitating the precise manufacturing and fabrication of complex components. This ensures that the parts can be produced accurately and efficiently, resulting in superior performance and reliability. 6. Good weldability: The special steel used in racing cars should have good weldability, as welding is often required for the assembly of various components. It should be able to withstand the heat generated during welding without experiencing significant loss in strength or other mechanical properties. In summary, the requirements for special steel used in high-performance racing cars revolve around strength, lightweight, heat resistance, corrosion resistance, machinability, and weldability. Meeting these requirements is essential to ensure the safety, performance, and success of racing cars on the track.

- Q: What is the role of special steel in sustainable manufacturing?

- Special steel plays a crucial role in sustainable manufacturing by offering numerous advantages that contribute to environmentally friendly production processes. Firstly, special steel is highly durable and has a long lifespan, which reduces the need for frequent replacement or repairs. This durability minimizes waste and extends the life cycle of products, reducing the overall environmental impact. Furthermore, special steel has excellent recyclability properties. It can be recycled multiple times without losing its quality or performance, making it a sustainable choice for manufacturers. By incorporating recycled special steel into the production process, manufacturers can reduce their reliance on virgin materials and decrease energy consumption and greenhouse gas emissions associated with the extraction and production of new steel. Moreover, special steel offers high strength and lightweight characteristics, enabling manufacturers to design products that are more energy-efficient. For example, in the automotive industry, using special steel in the manufacturing of vehicles reduces their weight, leading to improved fuel efficiency and lower emissions. This contributes to the reduction of carbon footprint and supports sustainable transportation. Special steel also plays a significant role in the production of renewable energy technologies. Wind turbines, solar panels, and hydropower systems require sturdy and resilient materials to withstand harsh conditions. Special steel provides the necessary strength, corrosion resistance, and durability required for these renewable energy infrastructure projects. By enabling the development of such technologies, special steel contributes to the growth of the renewable energy sector, which is essential for transitioning to a more sustainable energy mix. In conclusion, special steel plays a vital role in sustainable manufacturing by offering durability, recyclability, lightweight properties, and strength. By using special steel, manufacturers can reduce waste, energy consumption, and emissions, while also enabling the development of energy-efficient products and renewable energy technologies. Incorporating special steel into manufacturing processes is an essential step towards achieving a more sustainable and environmentally friendly future.

- Q: How does special steel perform in extreme cold temperatures?

- Special steel is specifically designed to perform well in extreme cold temperatures. It is made using alloys that have a low temperature ductility, meaning they can withstand and maintain their structural integrity even in extremely cold conditions. This type of steel is often used in applications such as Arctic exploration, oil and gas operations in cold environments, and in the aerospace industry. One of the key properties of special steel is its ability to resist brittleness at low temperatures. Unlike regular steel, which becomes brittle and prone to cracking in extreme cold, special steel retains its toughness, making it suitable for use in sub-zero conditions. This is achieved by carefully selecting and controlling the composition of the alloy, which allows for a better balance between strength and ductility. Furthermore, special steel has excellent corrosion resistance, which is particularly important in cold environments where exposure to snow, ice, and moisture is common. The alloying elements in special steel, such as chromium and nickel, form a protective oxide layer on the surface, preventing corrosion and maintaining the structural integrity of the steel. In addition, special steel also has good thermal conductivity, which means it can efficiently transfer heat even in extreme cold temperatures. This property is crucial in applications where heat management is essential, such as in the aerospace industry or in equipment operating in cold climates. Overall, special steel is specifically engineered to perform exceptionally well in extreme cold temperatures. Its low temperature ductility, resistance to brittleness, corrosion resistance, and thermal conductivity make it a reliable and durable material for various applications in cold environments.

- Q: What are the requirements for special steel used in oil and gas equipment manufacturing?

- Due to the demanding operating conditions and harsh environments that oil and gas equipment encounters, the requirements for special steel used in their manufacturing are extremely strict. These materials must meet several key requirements: 1. Excellent resistance to corrosion is essential for the special steel used in oil and gas equipment. This is particularly important in the presence of corrosive fluids like oil, gas, and saltwater. By preventing degradation and premature failure, corrosion resistance ensures the equipment's longevity. 2. The steel must possess high strength and toughness to withstand the extreme pressures, temperatures, and mechanical stresses encountered during oil and gas operations. This ensures that the equipment can perform reliably in demanding conditions. 3. Special steel used in oil and gas equipment must maintain its mechanical properties and structural integrity even at high temperatures, as these processes often involve elevated temperatures. 4. Weldability is an important aspect of special steel used in oil and gas equipment manufacturing. It should allow for efficient and reliable welding processes without compromising the equipment's overall strength and integrity. 5. Good fatigue resistance properties are necessary for special steel used in oil and gas equipment, as cyclic loading can lead to fatigue failure if the material is not designed to withstand repetitive stresses. 6. In applications like offshore drilling or arctic environments, where extremely low temperatures are encountered, the special steel should exhibit excellent toughness and ductility to prevent brittle fracture. 7. The chemical composition of the special steel must be tightly controlled to ensure consistent and predictable material properties. This involves strict control over the levels of various alloying elements, impurities, and trace elements to meet the specific requirements of the oil and gas industry. Meeting these requirements is crucial for the safe and reliable operation of oil and gas equipment. Special steel manufacturers collaborate closely with industry standards and specifications to develop and provide materials that meet these demanding requirements, ensuring the integrity and performance of the equipment in the oil and gas sector.

- Q: What are the applications of special steel in the automotive manufacturing process?

- Special steel has several applications in the automotive manufacturing process. It is commonly used in the production of engine components, such as crankshafts, camshafts, and connecting rods, due to its high strength and resistance to wear and tear. Special steel is also utilized in the manufacturing of suspension components, such as springs and shock absorbers, as it provides the necessary durability and resilience to withstand the constant stresses and strains of the vehicle's operation. Additionally, special steel is employed in the production of safety features, including seat belt pretensioners and airbag components, as it offers the required toughness and impact resistance. Overall, special steel plays a vital role in enhancing the performance, safety, and longevity of automotive vehicles.

- Q: How does special steel contribute to the electrical conductivity of products?

- Special steel contributes to the electrical conductivity of products by offering high levels of purity and low levels of impurities. Its composition and manufacturing process ensure that it has excellent conductivity and minimal resistance, allowing for efficient flow of electric current.

- Q: How does special steel contribute to the manufacturing of molds and dies?

- Special steel plays a crucial role in the manufacturing of molds and dies due to its exceptional properties such as high hardness, wear resistance, and toughness. These characteristics enable special steel to withstand the extreme pressures, temperatures, and abrasive forces involved in the molding and die casting processes. By using special steel in the production of molds and dies, manufacturers can ensure longer tool life, improved dimensional accuracy, and enhanced surface finish, ultimately leading to higher productivity and quality in the manufacturing industry.

- Q: What are the different methods for improving the heat resistance of special steel?

- There are various techniques available to enhance the heat resistance of special steel. These techniques comprise: 1. Alloying: Enhancing the heat resistance of steel can be achieved by alloying it with specific elements. The addition of chromium, nickel, or molybdenum, for instance, significantly augments the steel's ability to withstand high temperatures. 2. Heat treatment: Heat treatment processes like annealing, quenching, and tempering can be employed to enhance the heat resistance of special steel. These processes refine the steel's microstructure and enhance its mechanical properties, including heat resistance. 3. Surface modification: The heat resistance of special steel can be improved by applying specialized coatings or surface treatments. Processes such as nitriding, carburizing, or ceramic coating create a protective layer on the steel's surface, preventing oxidation and enhancing its ability to withstand high temperatures. 4. Grain refinement: Heat resistance can be improved by controlling the grain size of the steel through processes like grain refinement or recrystallization. Smaller grain sizes reduce the diffusion of atoms within the material, making it more resistant to high temperatures. 5. Precipitation hardening: Precipitation hardening involves the formation of small particles within the steel matrix, strengthening the material and improving its resistance to heat. This technique requires a specific heat treatment process to enable the formation of these particles. 6. Controlled cooling: Optimizing the cooling process after heat treatment can also enhance the heat resistance of special steel. By controlling the cooling rate, the formation of unwanted phases or microstructural defects can be minimized, ensuring better heat resistance. 7. Material selection: Selecting the appropriate type of special steel with inherent high heat resistance properties is another method to improve heat resistance. Stainless steel, tool steel, or superalloys, for instance, are renowned for their excellent heat resistance and are often chosen for applications involving high temperatures. It is important to note that the choice of the suitable method or combination of methods for enhancing heat resistance depends on the specific requirements and limitations of the application.

Send your message to us

Special Steel 6150 Steel/6150 Steel Round Bar/Tool Steel 6150

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords