Special Steel Sae 5160 6150 1.8159 Spring Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product information:

Size Tolerance:

Length tolerance: +100mm/-0mm

Straightness: max 3mm/m

Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation | Reduction of area | Hardness |

≥1225 | ≥ 1080 | ≥ 9 | ≥ 20 | <=321HB |

Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation | Reduction of area | Hardness |

≥1274 | ≥ 1127 | ≥ 10 | ≥ 40 | <=321HB |

Quality Contain

Both end of each bar must be cut.

Ladle furnanced and vacuum de-gassed

Show heat No. on each bar

Surface condition the surface of the hot rolled square bar shall befree cracks, scar and wrinkles that affect the use of the billets. In case there is the above-mentioned defect, it shall be remove.

The mill test certificate shall show the chemical composition, and it is guaranteed that the chemical composition shall be within the limit stipulated in the contract.

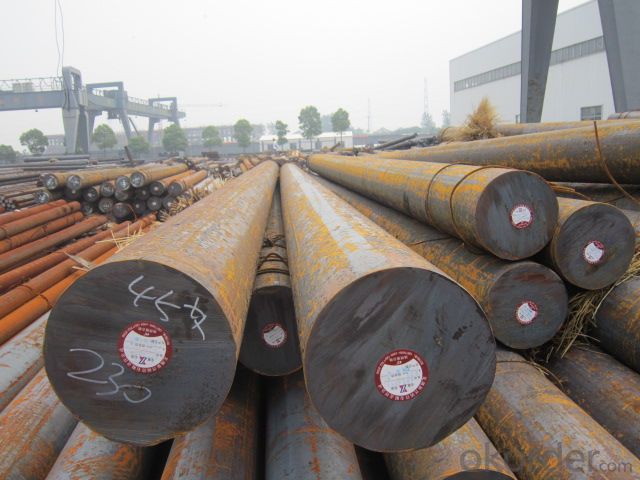

Product Show:

Workshop Show:

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: How are titanium alloys used in the medical industry?

- Titanium alloys are widely used in the medical industry due to their excellent biocompatibility, corrosion resistance, and high strength-to-weight ratio. These alloys are used for various medical applications such as implants, surgical instruments, and medical equipment. They are often used in orthopedic implants, dental implants, and cardiovascular devices, as they provide long-term stability and compatibility with the human body. Additionally, titanium alloys are highly resistant to bodily fluids and can withstand harsh sterilization processes, making them ideal for use in the medical field.

- Q: How does free-cutting steel improve machinability?

- Free-cutting steel improves machinability by incorporating additives such as sulfur or lead, which form small, brittle chips during the machining process. These chips help break the metal's continuous chip formation, resulting in improved chip control, reduced tool wear, and increased machining speeds. Additionally, free-cutting steel has improved surface finish and dimensional accuracy due to the formation of short, easily-managed chips.

- Q: How is special steel used in the oil and gas industry?

- Special steel is used extensively in the oil and gas industry due to its unique properties and high strength. It is specifically designed to withstand harsh environments, corrosion, and extreme temperatures. Special steel is used in various applications such as drilling equipment, pipelines, storage tanks, and valves, ensuring reliability and safety in the extraction, transportation, and processing of oil and gas.

- Q: What are the main advantages of using special steel in the defense industry?

- The main advantages of using special steel in the defense industry are its exceptional strength, durability, and resistance to wear and tear. Special steel alloys can withstand extreme conditions, such as high temperatures and pressures, making them ideal for military applications. Additionally, special steel offers enhanced corrosion resistance, ensuring the longevity of defense equipment even in harsh environments. Its high impact resistance and ability to absorb shock also make it valuable in protecting soldiers and military vehicles. Overall, special steel provides crucial advantages in terms of reliability, performance, and protection for the defense industry.

- Q: How does special steel contribute to the renewable energy conversion efficiency?

- Special steel plays a crucial role in improving the renewable energy conversion efficiency by offering enhanced mechanical properties, corrosion resistance, and temperature resistance. It is used in the manufacturing of various renewable energy components such as wind turbine blades, solar panels, and hydroelectric power systems. The strength and durability of special steel ensure that these components can withstand harsh environmental conditions, resulting in increased efficiency, reliability, and lifespan. Additionally, special steel's high thermal conductivity allows for efficient heat transfer in concentrated solar power plants, further optimizing energy conversion.

- Q: What industries rely on special steel?

- The exceptional properties and outstanding performance of special steel make it indispensable in several industries. The automotive sector, for instance, heavily relies on special steel for the manufacturing of engine components, suspension systems, gears, and various other parts. Similarly, the aerospace industry extensively utilizes special steel due to its ability to withstand high temperatures, extreme pressure, and provide exceptional corrosion resistance. In the construction industry, special steel plays a crucial role in the production of high-rise buildings, bridges, and infrastructure projects, where strength, durability, and resistance to environmental factors are of utmost importance. The energy sector, including oil and gas, heavily depends on special steel for the production of pipelines, drilling equipment, and storage tanks, as it possesses remarkable mechanical properties and can endure harsh operating conditions. Additionally, special steel is widely used in manufacturing, machinery, defense, and tooling industries for various applications such as molds, cutting tools, and machine components. In summary, special steel is extensively utilized in industries that prioritize superior performance, durability, and reliability in their products and equipment.

- Q: What are the main applications of special steel in the defense equipment?

- Special steel is widely used in defense equipment due to its exceptional properties such as high strength, durability, and corrosion resistance. It finds applications in various defense equipment including tanks, submarines, aircraft carriers, missile systems, armored vehicles, and military aircraft. Special steel is crucial for manufacturing components like armor plates, missile casings, propeller shafts, gun barrels, and other critical parts that require enhanced performance and reliability. Its usage ensures the defense equipment can withstand extreme conditions, resist wear and tear, and provide optimum protection and functionality to the armed forces.

- Q: How does special steel contribute to the defense sector?

- Special steel contributes to the defense sector in several ways. Firstly, it is used in the production of military vehicles, aircraft, and naval vessels, providing strength, durability, and resistance to extreme conditions. Secondly, special steel is utilized in the manufacturing of ballistic armor and bulletproof vests, offering enhanced protection to military personnel. Additionally, it is used in the construction of weaponry, such as firearms and artillery, ensuring reliability and precision. Overall, special steel plays a crucial role in enhancing the capabilities and safety of defense equipment and personnel.

- Q: What are the different methods for shot peening special steel?

- The fatigue strength and performance of special steels can be improved through the widely used method of shot peening. Different methods exist for shot peening special steel, each with its own advantages and considerations. One method is air shot peening, which involves propelling small steel shots at high speeds using compressed air. This method is commonly used and effective for treating large surfaces and achieving uniform coverage. However, it may not be suitable for delicate or highly sensitive materials. Another method is wheel shot peening, where steel shots are propelled using a rotating wheel. This method offers better control and accuracy, making it effective for treating small or intricate parts such as gears and shafts. Wet shot peening is a method performed in a wet environment, typically using a mixture of water and shot media. It provides increased control over shot flow and reduces dust formation. This method is preferred for special steels sensitive to heat or at risk of distortion. Ultrasonic shot peening is an advanced method that utilizes high-frequency vibrations to propel the shot media onto the steel surface. It offers enhanced control over shot velocity and impact energy, resulting in improved surface finish and fatigue life. It is particularly useful for thin or delicate special steels. Laser shot peening employs laser pulses to generate shockwaves on the steel surface, creating compressive residual stresses. This method is highly precise and can be controlled to treat specific areas or patterns. It is commonly used for special steels requiring localized treatment or with complex geometries. The selection of the shot peening method depends on various factors, including the type of special steel, component geometry, required surface finish, and desired residual stress profile. Consulting with shot peening experts or engineers is essential to determine the most suitable method for shot peening special steel.

- Q: What are the requirements for special steel used in textile machinery?

- The requirements for special steel used in textile machinery include high strength and durability, excellent corrosion resistance, good wear resistance, and the ability to withstand high temperatures and pressures. Additionally, the steel should have good machinability and be able to maintain dimensional stability under various operating conditions.

Send your message to us

Special Steel Sae 5160 6150 1.8159 Spring Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords