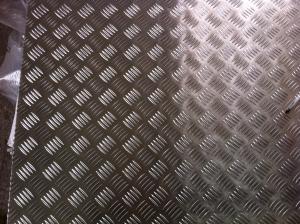

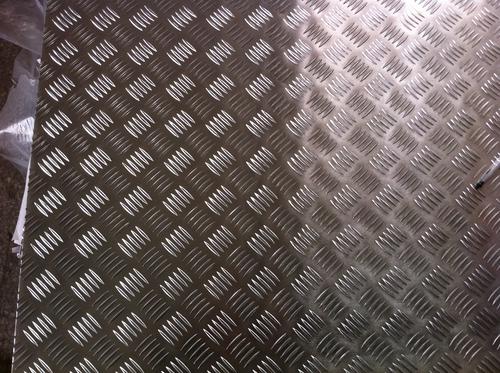

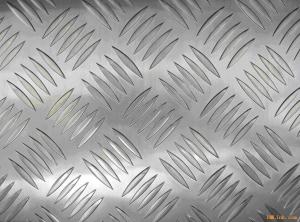

Aluminum Roofing Sheets - Small Five Bar Treadplate in Ghana

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SMALL FIVE BAR TREADPLATE

1) Alloy: 1050. 1060, 1100, 1070, 1200, 3003 5052 5754 5083 5086 6061 6061 7075

2) Temper: soft, 1/4 hard, 1/2 hard, hard, H12, H14

3) Thickness: 0.2mm to 300mm

4) Width: 100mm to 2300mm, Length: up to 2300mm,

5) Main application: Tray, Road traffic signs, Car license, Automotive body, Wall decoration

Specification | Name: 1XXX series Aluminum Five Bar Plate |

Alloy: 1050, 1060, 1100, 1200 etc. | |

Temper: O, H12, H22, H14, H24, H26, H18 etc. | |

Thickness: 1.5-12mm | |

Width: Up to 1500mm | |

Length: Up to 6000mm | |

Type: big five bars, small five bars | |

Feature | Price is much more competitive than that of other series. |

Satisfy regular industrial process of stamping, drawing with good elongation, tensile strength and high formability. | |

Great plasticity, corrosion resistance, electrical conductiviy and termal conductivity. | |

Easy to be welded. | |

Easy to be pressure processed, extended and bent. | |

Application | Sign board, Advertising board, Building decoration, Car body, Cooking utensil, Lamp holder, Fan leaf, Electrical part, Chemical instrument, Machined part, Deep-drawn or spinned part, Welded part, Heat exchanger, Clock surface, Decotation, Reflective instrument etc. |

- Q: Should I purchase a camper made out of aluminum/wood or a fiberglass?I'm looking to purchase a small camper, approx 18', to tow on the back of my SUV. It's a 2011 Wildwood camper. However, I hear campers made out of aluminum and wood aren't very good because the wood can ruin in time and the aluminum can rust, etc. I hear fiberglass campers are better? Anyone have any knowledge or experience with this? Also, any thoughts or advice with brands/models? And about the Wildwood? Thanks in advance.

- Aluminum is lighter so it offers economies over the life of the trailer. The Airstream has been built almost as long as I've been around. It is true that the wood does rot And some care is needed to stop the occasional leak. Fiberglass is heaver and has it's own maintenance issues. I've no experience with the Wildwood. What I do know is that motor homes are dirt cheap right now. You might think about taking advantage of the economy and pick-up a motor home at a bargain.

- Q: What are the common applications of aluminum sheets?

- Aluminum sheets find widespread use in various industries, offering a multitude of applications. Within the construction industry, they are highly utilized for roofing, siding, and facades due to their lightweight nature, resistance to corrosion, and durability. The transportation industry also heavily relies on aluminum sheets, particularly for the production of vehicles and aircraft. Their exceptional strength-to-weight ratio makes them perfect for constructing car bodies, truck beds, and airplane components. Moreover, aluminum sheets play a significant role in the packaging industry, where they are employed in the creation of cans, foils, and closures. The remarkable thermal and electrical conductivity of aluminum also positions it as a popular choice for heat sinks, electrical enclosures, and electronic parts. Additionally, the marine industry benefits from the use of aluminum sheets in boat building, while appliances like refrigerators and cookware also incorporate aluminum in their manufacturing process. Ultimately, the versatility and advantageous properties of aluminum sheets establish their indispensability across various sectors.

- Q: Can aluminum sheets be an alternative to ceramics in certain applications?

- Certainly! In certain applications, aluminum sheets can serve as a viable alternative to ceramics. Aluminum sheets possess numerous advantages over ceramics, including their lightweight nature, affordability, and ease of shaping and fabrication. Moreover, they exhibit exceptional thermal and electrical conductivity, making them suitable for applications requiring heat dissipation or electrical conduction. Additionally, aluminum sheets possess the ability to endure high temperatures and display commendable resistance to corrosion. However, ceramics retain their distinctive properties and strengths, such as heightened hardness, improved chemical resistance, and superior insulation capabilities, which may render them more suitable for specific applications. Consequently, the appropriateness of employing aluminum sheets as a substitute for ceramics would rely on the precise requirements and circumstances of the given application.

- Q: Can someone explain the movement of electrons in a pure block of aluminum metal? At they free to move around between similar energy levels? Are they bound to Al atoms? What about orbital overlap?

- Any element that allows the transfer of electrical flow to move across it usually has the characteristic of having free movement electrons in the outer shell. This is why metals are particularly good at electrical conduction. The best metal for transferring electrical charge is silver followed by copper and then aluminum. Much electrical wire is made from pure aluminum because it is cheaper than copper or silver and the resistance to flow is only slightly lower than copper. The electrons in the outer shells are still bound to the aluminum nucleus but they are free to accept a charge from neighboring aluminum atoms and transfer that charge to the next aluminum in the electrical flow. This is basically the definition of electrical resistance. Copper performs this transfer more efficiently than aluminum so it's electrical resistivity is less than aluminums. But in both base metals, the outer electrons never leave the atom, they simply transfer their charge to the next atom in line

- Q: How does the alloy composition affect the mechanical properties of aluminum sheet?

- The alloy composition of aluminum sheet plays a significant role in determining its mechanical properties. The inclusion of different elements in the alloy can influence its strength, hardness, ductility, and other characteristics. For instance, adding small amounts of copper or manganese can enhance the strength of aluminum, while magnesium can improve its corrosion resistance. Additionally, the size and distribution of alloying elements within the sheet can also impact its mechanical properties. Therefore, careful selection of alloy composition is crucial to achieve the desired mechanical performance of aluminum sheet.

- Q: Can aluminum sheets be used for electronic enclosures?

- Yes, aluminum sheets can be used for electronic enclosures. Aluminum is a commonly used material for electronic enclosures due to its excellent properties. It is lightweight, corrosion-resistant, and provides good electromagnetic shielding. Aluminum sheets can be easily formed and fabricated into various shapes and sizes, making them suitable for housing electronic components. Furthermore, aluminum has good thermal conductivity, allowing for efficient heat dissipation from the enclosed electronics. Overall, aluminum sheets are a popular choice for electronic enclosures due to their durability, versatility, and electrical properties.

- Q: Can aluminum sheets be used for flooring?

- Yes, aluminum sheets can be used for flooring. Aluminum is a lightweight and durable material that is resistant to corrosion, making it a suitable choice for various flooring applications. Aluminum sheets are often used in industrial, commercial, and residential settings, including warehouses, garages, kitchens, and outdoor spaces. They offer good strength, easy installation, and low maintenance. Additionally, aluminum flooring can provide a sleek and modern appearance to any space. However, it is important to consider factors such as thickness, finish, and the specific requirements of the flooring project before selecting aluminum sheets.

- Q: Can aluminum sheets be used for decorative ceilings?

- Yes, aluminum sheets can be used for decorative ceilings. Aluminum is a versatile material that can be shaped into various designs and patterns, making it suitable for creating visually appealing ceilings. It is lightweight, durable, and resistant to corrosion, which makes it a popular choice for decorative applications. Additionally, aluminum sheets can be powder-coated or painted in different colors to match the desired aesthetic of the space. Whether it is for residential or commercial purposes, aluminum sheets offer a modern and stylish option for creating decorative ceilings.

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Yes, aluminum sheets are suitable for use in HVAC systems. They offer several advantages such as high thermal conductivity, corrosion resistance, and lightweight nature, making them ideal for efficient heat transfer and durability in HVAC applications.

- Q: What are the mechanical properties of aluminum sheets?

- Aluminum sheets possess several mechanical properties, including high strength-to-weight ratio, excellent corrosion resistance, good formability, and high thermal and electrical conductivity. They are also non-magnetic and non-toxic, making them suitable for various applications in industries such as aerospace, automotive, construction, and packaging.

Send your message to us

Aluminum Roofing Sheets - Small Five Bar Treadplate in Ghana

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords