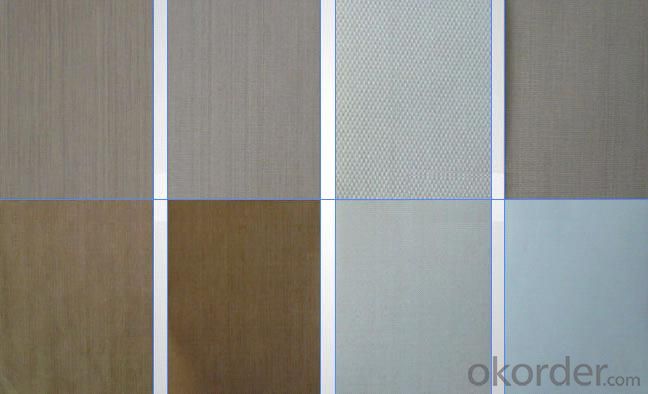

Vermiculite-Coated Fiberglass Fabric in Different Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicone Coated Fiberglass Fabric of Different Colors

Fiberglass Fabric Description

Silicone coated fiberglass fabric is a fiberglass cloth, which possesses the properties of temperature resistance, anti-corrosion, high strength and is coated with organic silicone rubber.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

It has been widely used in construction, electric insulation,

chemical industry, pipeline ductile conjunction, large generating

Corrosion proofing field, machinery, metallurgy, sealing and so on.

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

c) Satin weave: compared with plain weave and twill weave, it is of high density,high intensity, with a soft and loose structural weave with a good texture. It is applicable for use as a higher reinforced material in machinery.

d).Gauze weave: said lattice twist weave. It can be used in spread model curtain,resin reinforced emery wheel gray cloth and lattice embed belt.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q: What is the melting point of fiberglass fabric?

- The melting point of fiberglass fabric fluctuates based on the fabric's specific type and composition. Typically, fiberglass fabric possesses a melting point that spans from 1000 to 1400 degrees Celsius (or 1832 to 2552 degrees Fahrenheit). Nevertheless, it is crucial to acknowledge that fiberglass fabric typically begins to deteriorate and compromise its structural stability at temperatures considerably lower than its melting point. Consequently, it is advised to refrain from subjecting fiberglass fabric to elevated temperatures in order to avert any possible harm or safety risks.

- Q: Is fiberglass fabric resistant to chemicals in oil and gas industry?

- Yes, fiberglass fabric is generally resistant to chemicals in the oil and gas industry. It is known for its excellent chemical resistance properties, making it a suitable material for various applications in this industry.

- Q: Can fiberglass fabric be used in automotive applications?

- Yes, fiberglass fabric can be used in automotive applications. It is commonly used in various parts of the automotive industry, such as in the manufacturing of body panels, interior components, and insulation. Fiberglass fabric offers excellent strength-to-weight ratio, durability, and resistance to heat, making it suitable for automotive applications where lightweight and high-performance materials are required.

- Q: What is the typical width of fiberglass fabrics?

- The typical width of fiberglass fabrics can vary, but it is commonly found in widths ranging from 36 to 60 inches.

- Q: How about the difference between glass fiber cloth and ordinary chemical fiber cloth?

- My major is chemical fiber. It's easy to tell apart! You can burn it with a fire. It can melt and drop like a candle. (careful not to stick to your body and burn it!) It's a synthetic fabric, not a fiberglass fabric.

- Q: Are there any environmental considerations associated with fiberglass fabrics?

- Yes, there are several environmental considerations associated with fiberglass fabrics. Firstly, the production of fiberglass fabrics involves the extraction of raw materials, such as silica sand and limestone, which can have negative impacts on the environment due to habitat destruction and landscape alteration. Additionally, the manufacturing process of fiberglass fabrics requires significant energy consumption, which contributes to greenhouse gas emissions and climate change. Furthermore, the use of fiberglass fabrics often involves the use of toxic chemicals, such as resins and adhesives, which can be harmful to both human health and the environment. These chemicals can potentially leach into soil and water sources, posing risks to ecosystems and biodiversity. Moreover, fiberglass fabrics are not biodegradable and can persist in the environment for a long time. If not properly managed at the end of their life cycle, they can contribute to waste accumulation in landfills or incineration, both of which have their own environmental impacts. However, it is important to note that fiberglass fabrics also have some positive environmental aspects. They are highly durable and have a long lifespan, which can reduce the need for frequent replacements, thus saving resources. Additionally, fiberglass fabrics can have energy-saving properties when used in insulation and construction materials, which can contribute to reducing energy consumption and greenhouse gas emissions in the long run. Overall, while there are environmental considerations associated with fiberglass fabrics, their impact can be mitigated through sustainable production practices, proper waste management, and consideration of alternative, more eco-friendly materials.

- Q: Are fiberglass fabrics biodegradable?

- Fiberglass fabrics, unfortunately, are not biodegradable. These fabrics consist of interwoven glass fibers, forming a robust and long-lasting material. Given that glass lacks the ability to naturally decompose, fiberglass fabrics do not disintegrate over time. Consequently, when disposed of, these fabrics can add to the problem of environmental pollution and waste buildup. To mitigate their adverse effects on the environment, it is crucial to recycle or dispose of fiberglass fabrics appropriately.

- Q: Can fiberglass fabrics be used for insulation purposes?

- For insulation purposes, fiberglass fabrics are a suitable option. These fabrics consist of extremely fine glass fibers that are woven together, resulting in a material that is lightweight and flexible. The excellent insulation properties of this fabric are due to its ability to trap air and prevent the transfer of heat or cold. Commonly used in insulation applications, fiberglass fabrics are employed for insulating pipes, ducts, walls, and roofs. They are also utilized in the production of thermal blankets and curtains designed for insulation purposes. Moreover, fiberglass fabrics can be combined with other insulating materials to enhance their overall effectiveness. One of the main advantages of using fiberglass fabrics for insulation is their high thermal resistance. With a low thermal conductivity, these fabrics can significantly reduce heat transfer and maintain stable temperatures in insulated areas. Additionally, fiberglass fabrics are non-combustible and exhibit good resistance to moisture and chemicals, making them suitable for a wide range of insulation applications. Furthermore, fiberglass fabrics are easy to handle and install. They can be easily cut and shaped to fit specific dimensions, and can be attached to surfaces using mechanical fasteners or adhesive. Due to their flexibility and ease of installation, fiberglass fabrics are a popular choice for insulation projects in both residential and commercial settings. To conclude, fiberglass fabrics are an excellent option for insulation purposes. Their high thermal resistance, durability, and ease of installation make them a versatile and effective solution for various insulation applications.

- Q: Can fiberglass fabric be used for medical devices?

- Yes, fiberglass fabric can be used for medical devices. It is commonly used in applications such as wound dressings, orthopedic casts, and splints due to its lightweight, high strength, and flexibility. Furthermore, its biocompatible properties make it suitable for medical use as it does not cause any adverse reactions or allergies in patients.

- Q: How is fiberglass fabric used in the production of windbreakers?

- Fiberglass fabric is commonly used in the production of windbreakers due to its unique properties that make it suitable for this application. Windbreakers need to be lightweight, durable, and able to withstand harsh weather conditions, and fiberglass fabric offers all these qualities. One way fiberglass fabric is used in windbreaker production is as a reinforcement material. It is often incorporated into certain parts of the windbreaker, such as the shoulders, elbows, or hood, to provide extra strength and durability. Fiberglass fabric acts as a protective layer, preventing tears or rips in these high-stress areas, making the windbreaker last longer and perform better. Additionally, fiberglass fabric is known for its excellent thermal insulation properties. Windbreakers are designed to keep the wearer warm and comfortable in windy or chilly weather, and the fiberglass fabric helps in achieving this goal. It acts as a barrier against wind, preventing it from penetrating through the fabric and stealing body heat. This insulation property helps retain the warmth generated by the body, keeping the wearer cozy even in harsh weather conditions. Moreover, fiberglass fabric is lightweight, which is essential for windbreaker production. Windbreakers are typically designed to be portable and easy to carry, making them ideal for outdoor activities like hiking or camping. The lightweight nature of fiberglass fabric ensures that the windbreaker remains comfortable and doesn't add unnecessary bulk to the wearer. Lastly, fiberglass fabric is water-resistant, which is another crucial feature for windbreakers. It helps repel water and keeps the wearer dry during light rain or drizzles. This property is particularly important for outdoor enthusiasts or individuals who engage in activities in damp or unpredictable weather conditions. In conclusion, fiberglass fabric is utilized in the production of windbreakers due to its reinforcement capabilities, thermal insulation properties, lightweight nature, and water resistance. These qualities make fiberglass fabric an excellent choice for ensuring durability, comfort, and protection from wind and other weather elements in windbreaker designs.

Send your message to us

Vermiculite-Coated Fiberglass Fabric in Different Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords