Fabric Fiberglass Cloth with Vermiculite Coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

Fiberglass cloth coated vermiculite is a kind of high-temperature resistant products which fiberglass cloth coated by vermiculite.

Application:

Suitable for insulation for hard and soft pipe;

Thermal insulation cover,refractory shell,other insulation layer for heating machine and freezers;

Reinforcement materials for fiber reinforcement plastics like vessel,vehicle,stock tank,panel,furniture;

Movable thermal insulation cover,fireproof blanket,fireproof curtain,expansion joints and fume ductwork.It can be made into high temperature fireproof cloth and gloves which ca-n be used at high-temperature work like fireproof,stainless steel and industry;

Heat shield curtain,prevent molten liquid,welding blanket.

Product Capability:

Higher temperature resistant,thermal insulation,low thermal conductivity;

Thermal stability and chemical stability;

Higer wire resistance;

Nontoxic and harmless to the environment.

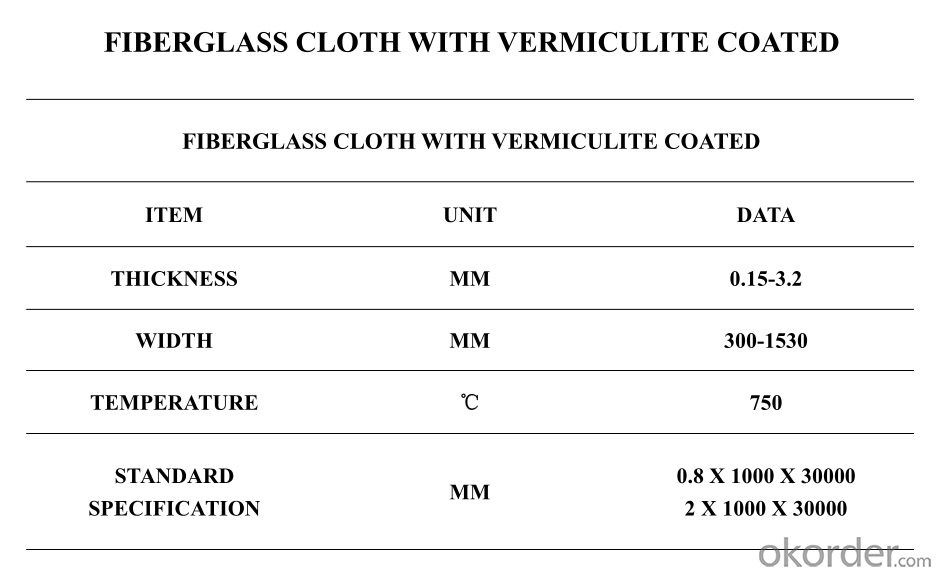

Data Sheet:

:

Fiberglass products:

Fiberglass is a kind of long fiber. It has the advantage of high tensile strength, low thermal conductivity, corrosion resistance and good insulation.The working temperature ranges from 200-1000 degree Celsius. Main products: Fiberglass texturized yarn, cloth, tape, rope, sleeve,mesh,filter cap,friction thread (piece) and fiber netting,composite yarn etc.

- Q: Can fiberglass fabric be used for reinforcing concrete?

- Yes, fiberglass fabric can be used for reinforcing concrete. Fiberglass fabric is a lightweight and strong material made from fine glass fibers. It is commonly used as a reinforcement material in various industries, including construction. When used in concrete reinforcement, fiberglass fabric helps to improve the tensile strength and durability of the concrete structure. Fiberglass fabric is particularly beneficial in concrete reinforcement due to its high strength-to-weight ratio. It provides excellent resistance to corrosion, chemical attack, and weathering, making it suitable for both interior and exterior applications. Additionally, fiberglass fabric is non-magnetic and non-conductive, making it a preferred choice in areas where electromagnetic interference or conductivity is a concern. The process of using fiberglass fabric for reinforcing concrete involves laying the fabric in between the layers of wet concrete during the construction process. The fabric acts as a reinforcement, distributing the tensile stresses across the entire concrete structure, thus increasing its overall strength and preventing cracks or fractures. Furthermore, fiberglass fabric is relatively easy to handle and install. It can be cut into different shapes and sizes to fit specific reinforcement requirements. The fabric can also be easily molded or wrapped around complex shapes, allowing for versatile use in various concrete structures such as beams, columns, walls, and slabs. Overall, fiberglass fabric is a reliable and effective material for reinforcing concrete. It offers numerous advantages, including high strength, resistance to corrosion, and ease of installation. Its use in concrete reinforcement helps to enhance the structural integrity and longevity of the concrete, making it a popular choice in the construction industry.

- Q: Sofa three proofing fabric and 6 anti distinction

- Three proof cloth is PVC coated glass fiber cloth. Three cloth is coated on the surface of PVC, PTFE refractory fiber, flame retardant silicone and other refractory materials, make fire waterproof mildew proof function, refractory fiber with fire, PVC, PTFE, silica gel has a waterproof function.

- Q: Are fiberglass fabrics resistant to UV degradation?

- Yes, fiberglass fabrics are generally resistant to UV degradation. Fiberglass is made from fine strands of glass woven together to create a strong and durable fabric. These glass fibers have inherent resistance to the harmful effects of UV radiation. This means that fiberglass fabrics can withstand prolonged exposure to sunlight without significant degradation. However, it is important to note that while fiberglass itself may be UV resistant, the coatings or finishes applied to the fabric may not be. Therefore, it is advisable to check the specific product specifications or consult with the manufacturer to ensure the level of UV resistance of a particular fiberglass fabric.

- Q: Is fiberglass fabric suitable for making outdoor cushions?

- Indeed, outdoor cushions can be crafted with fiberglass fabric, which is renowned for its durability, strength, and ability to withstand diverse weather conditions. This fabric proves to be a fitting selection for outdoor purposes as it resists fading, UV rays, and mold, which are prevalent concerns for outdoor cushions. Moreover, fiberglass fabric often possesses water-resistant or water-repellent properties, rendering it ideal for outdoor use where cushions may encounter rain or other forms of moisture. Ultimately, fiberglass fabric provides a dependable and enduring choice for outdoor cushions, guaranteeing their ability to withstand the elements and uphold their superior quality throughout time.

- Q: How is fiberglass fabric cleaned and maintained?

- Achieving cleanliness and maintaining fiberglass fabric is easily accomplished through a few uncomplicated measures. Initial attention should be given to eliminating loose dirt or debris from the fabric by employing gentle brushing or vacuuming techniques. This preliminary action serves to prevent particles from becoming embedded within the fabric during the subsequent cleaning process. Next, it is imperative to concoct a cleaning solution by blending mild detergent or soap with warm water. It is advised to refrain from employing harsh chemicals or bleach, as these substances possess the potential to inflict damage upon the fabric. Submerge a soft cloth or sponge into the prepared cleaning solution and proceed to cautiously scrub the fiberglass fabric. Care should be taken to avoid exerting excessive pressure, as doing so may result in the stretching or tearing of the fabric. Upon completing the scrubbing phase, it is necessary to thoroughly rinse the fabric with clean water to eradicate any lingering traces of soap. The removal of all vestiges of detergent is crucial as it serves to deter future accumulation of dirt. Following the rinsing process, it is recommended to allow the fabric to air dry completely. The utilization of a dryer or exposure to direct sunlight should be avoided, as these factors may contribute to shrinkage or fading. To ensure the fabric's cleanliness is maintained, it is advisable to regularly brush or vacuum its surface to eliminate any superficial grime. Additionally, when not in use, storing the fabric in a clean and dry location is highly recommended, as this measure will impede the accumulation of dust or debris. By adhering to these straightforward steps for cleaning and maintenance, fiberglass fabric can remain in optimal condition and endure for an extended duration.

- Q: Can fiberglass fabric be used for making flexible hoses?

- Certainly! Flexible hoses can be made using fiberglass fabric. This material is renowned for its exceptional strength and flexibility, rendering it suitable for a wide range of purposes. Notably, it is commonly employed in the production of flexible hoses due to its unique attributes. By weaving the fabric into a flexible structure, it becomes capable of enduring bending, twisting, and stretching without compromising its integrity. Furthermore, fiberglass fabric exhibits resistance against high temperatures, chemicals, and abrasion. This outstanding feature makes it highly suitable for hoses that transport fluids, gases, and even solids. Given its durability and flexibility, it comes as no surprise that fiberglass fabric is extensively utilized in demanding industries such as automotive, aerospace, and construction, where hoses are constantly exposed to rigorous conditions.

- Q: How is fiberglass fabric stored and handled?

- Fiberglass fabric should be stored and handled with care to maintain its quality and prevent any damage. When it comes to storage, it is recommended to keep the fabric in a cool, dry place to avoid exposure to moisture or extreme temperature fluctuations. Ideally, it should be stored in a sealed bag or container to protect it from dust, dirt, and any potential contaminants. When handling fiberglass fabric, it is important to wear protective gloves to prevent any irritation or skin reactions. Additionally, wearing safety goggles or a face shield is recommended to protect the eyes from any loose fibers. During transportation or handling, it is advisable to avoid any sharp objects or rough surfaces that can cause tears or abrasions to the fabric. Care should be taken to avoid any unnecessary bending or folding, as this can lead to permanent creases or weak spots in the material. If the fabric needs to be cut or trimmed, it is recommended to use sharp scissors or a utility knife to ensure clean and precise cuts. It is also advisable to work in a well-ventilated area or wear a dust mask to minimize the inhalation of any loose fibers. In summary, fiberglass fabric should be stored in a clean and dry environment, handled with protective gear, and protected from any potential damage during transportation or cutting. By following these guidelines, the lifespan and quality of the fiberglass fabric can be preserved.

- Q: Can fiberglass fabric be dyed or printed on?

- Yes, fiberglass fabric can be dyed or printed on. However, it is important to use specific dyes and printing techniques suitable for fiberglass to ensure proper adhesion and durability of the color or print.

- Q: Is non-woven fabric and fiberglass all the same?

- Just do it in nonwoven production line products referred to as non-woven fabrics, like eating rice, glutinous rice, rice, black rice, red rice called rice

- Q: What are the weight options for fiberglass fabric?

- Fiberglass fabric, also known as glass fiber cloth, is available in a variety of weight options to suit different applications. The weight of fiberglass fabric is typically measured in ounces per square yard (oz/yd²) or grams per square meter (g/m²). The weight options for fiberglass fabric can range from as low as 0.5 oz/yd² (17 g/m²) to as high as 32 oz/yd² (1086 g/m²) or even more. The weight of fiberglass fabric determines its thickness, strength, and durability. Lighter weight fiberglass fabrics are often used for applications that require high flexibility and conformability, such as in the manufacturing of circuit boards or for reinforcing and repairing small parts. They are also commonly used in aviation and aerospace industries, where weight reduction is crucial. On the other hand, heavier weight fiberglass fabrics are typically used in applications that require higher strength and impact resistance. These can include boat building, automotive parts manufacturing, construction, and even in the production of bulletproof vests and armor. It is important to note that the weight of fiberglass fabric is just one factor to consider when choosing the right fabric for a specific application. Other factors like weave pattern, finish, and resin compatibility should also be taken into account to ensure optimal performance.

Send your message to us

Fabric Fiberglass Cloth with Vermiculite Coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords