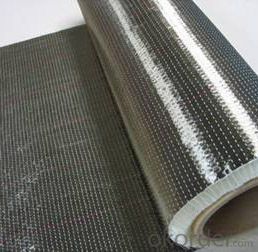

Carbon Fiber Fiberglass Release Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

With raw material of carbon fiber yarn from Toray or Mitsubishi Japan , our company can produce both woven fabric and knitted fabric, including unidirectional fabrics, plain weave fabric, twill fabric, satin fabric and multi-axial fabrics. The main use of carbon fabric is to make structural materials reinforced with resin, metal, and ceramic etc. Among the existing structural materials, carbon fiber reinforced epoxy resin composites have the highest specific strength and modulus. In the areas of strict requirements on density, stiffness, weight, fatigue characteristics, high temperature and high chemical stability, CFRP have an outstanding advantage.

Product Features:

● Light weight

● Products high strength, high modulus

● Superior acid corrosion resistance

Product Specifications:

Density:100-400g/m2.

Item:1k,2k,3k,6k,12k.

Weave:Plain,Twill,Satin,Multiaxial,UD。

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 225mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: What is the typical thickness range for fiberglass fabrics?

- The typical thickness range for fiberglass fabrics is between 0.1mm to 3mm.

- Q: Can fiberglass fabric be used for architectural applications?

- Yes, fiberglass fabric can be used for architectural applications. It is commonly used in the construction industry for various purposes such as reinforcing walls, ceilings, and floors, as well as providing insulation and soundproofing. It is lightweight, durable, and offers excellent resistance to fire, chemicals, and weather conditions, making it a suitable choice for architectural projects.

- Q: Can fiberglass fabric be used for heat-resistant gloves?

- Yes, fiberglass fabric can be used for heat-resistant gloves. Fiberglass is known for its excellent heat resistance properties, making it an ideal material for gloves used in high-temperature environments. The fabric is capable of withstanding extreme heat and does not easily catch fire or melt. Additionally, fiberglass fabric is lightweight and flexible, allowing for comfortable use while providing protection against heat hazards. However, it is important to note that gloves made from fiberglass fabric may not be suitable for handling open flames or direct contact with hot surfaces, as the material can still transfer heat through conduction. Therefore, it is recommended to choose gloves specifically designed for the intended heat application.

- Q: Can fiberglass fabric be used for making curtains or dividers?

- Fiberglass fabric is capable of being utilized in the creation of curtains or dividers. Its reputation lies in its durability, strength, and fire resistance, rendering it an appropriate material for these purposes. Additionally, it possesses a lightweight and flexible nature, facilitating effortless manipulation and installation. Furthermore, fiberglass fabric boasts easy cleaning and maintenance, making it a practical selection for curtains or dividers across diverse settings, including homes, offices, and industrial spaces.

- Q: What is waterproof, one cloth, four coated?

- One cloth, four coating is a waterproof construction process, that is, a glass cloth, four times brushing cement based waterproof coating.

- Q: How is fiberglass fabric different from other types of fabric?

- Fiberglass fabric is different from other types of fabric primarily due to its composition and unique properties. Unlike natural fabrics such as cotton or silk, fiberglass fabric is made from thin strands of glass that are woven together to form a textile material. This unique composition gives fiberglass fabric several distinct advantages over other types of fabric. Firstly, fiberglass fabric is known for its exceptional strength and durability. The glass fibers used in its production are incredibly strong and resistant to tearing, stretching, and general wear and tear. This makes fiberglass fabric ideal for applications that require a high level of durability, such as in the construction industry or for industrial purposes. Secondly, fiberglass fabric is highly heat-resistant. The glass fibers used in its production have a high melting point, which allows the fabric to withstand extreme temperatures without deteriorating or catching fire. This property makes fiberglass fabric suitable for use in applications where heat resistance is crucial, such as in fire-resistant clothing or insulation materials. Additionally, fiberglass fabric has excellent chemical resistance. It is not easily affected by most chemicals, including acids, alkalis, and solvents. This makes fiberglass fabric a preferred choice in industries where exposure to corrosive substances is common, such as chemical processing or automotive manufacturing. Moreover, fiberglass fabric is known for its lightweight nature. Despite its strength and durability, fiberglass fabric is relatively light, making it easier to handle and transport compared to other heavy-duty fabrics. This lightweight property is particularly advantageous in applications where weight is a concern, such as in aerospace or automotive industries. Lastly, fiberglass fabric has excellent insulation properties. It is a poor conductor of heat and electricity, making it an effective insulator. This insulation capability is beneficial in various applications, including thermal insulation for buildings, electrical insulation for wiring, or even in the production of protective clothing for workers in extreme environments. In conclusion, fiberglass fabric stands out from other types of fabric due to its exceptional strength, heat resistance, chemical resistance, lightweight nature, and insulation properties. Its unique composition and advantageous properties make it a versatile and preferred choice in various industries and applications.

- Q: How does fiberglass fabric handle UV exposure?

- Fiberglass fabric is known for its excellent resistance to UV exposure. The material is made by weaving together fine strands of glass, which are inherently resistant to damage from the sun's ultraviolet rays. This means that fiberglass fabric can withstand prolonged exposure to sunlight without experiencing significant degradation or weakening. The glass fibers in fiberglass fabric are typically coated with a protective layer, such as a resin or polymer, which further enhances its UV resistance. This coating acts as a barrier, shielding the glass fibers from direct contact with the UV rays and preventing any potential damage. Additionally, the coating helps to maintain the fabric's strength and integrity over time, even when exposed to harsh sunlight. As a result of its UV resistance, fiberglass fabric is commonly used in outdoor applications where exposure to sunlight is expected. It is often used in the construction industry for roofing, insulation, and cladding, as well as in the automotive sector for various exterior components. The fabric's ability to withstand UV exposure makes it a durable and long-lasting choice for these applications. However, it is important to note that while fiberglass fabric is highly resistant to UV rays, it is not completely immune to their effects. Prolonged and intense exposure to sunlight can eventually lead to some minor degradation, such as fading or discoloration. This is a natural process that occurs over an extended period of time and does not significantly impact the fabric's structural integrity or performance. To maintain the longevity of fiberglass fabric when exposed to UV rays, it is recommended to apply a protective coating or finish specifically designed for UV protection. Regular cleaning and maintenance can also help to prolong the fabric's lifespan and ensure its continued resistance to UV exposure.

- Q: Can fiberglass fabric be used for reinforcement in bridge structures?

- Yes, fiberglass fabric can be used for reinforcement in bridge structures. It is a commonly used material due to its high strength, durability, and resistance to corrosion. Fiberglass fabric provides excellent reinforcement and can be easily molded to fit the desired shape, making it a suitable option for strengthening and enhancing the structural integrity of bridge components.

- Q: How does fiberglass fabric compare to other types of fabrics?

- Fiberglass fabric stands out from other types of fabrics due to its unique properties. It is highly durable, fire-resistant, and can withstand extreme temperatures. Additionally, it is lightweight, flexible, and offers excellent insulation properties. However, fiberglass fabric is less comfortable compared to natural or synthetic fabrics, and it may be less breathable. Overall, its exceptional strength and resistance make it a preferred choice for applications requiring high-performance fabrics.

- Q: Glass fiber cloth, heat conduction double sided adhesive tape and no material heat conduction double sided adhesive tape difference? Which is better?

- Fiberglass cloth thermal double-sided tape (www.glpoly ): it is made of glass fiber cloth, PET, PVC film, non-woven material, double-sided evenly coated elastomer pressure-sensitive adhesive or resin adhesive, acrylic pressure-sensitive adhesive, adhesive made in the substrate roll or sheet belt, is composed of a substrate, adhesive, isolation of paper (film) parts.

Send your message to us

Carbon Fiber Fiberglass Release Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords