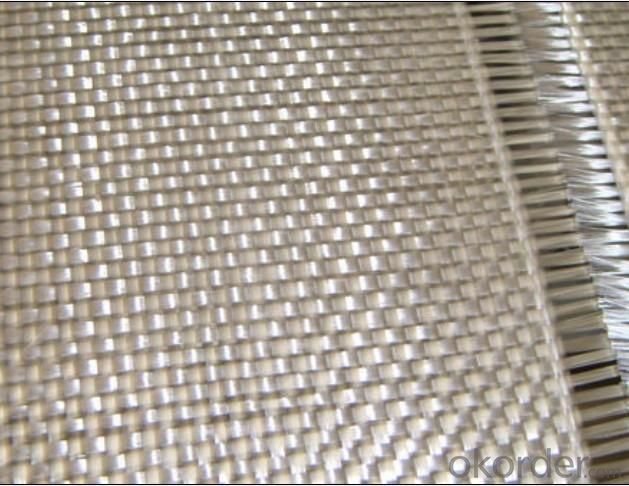

Good Quality Fiberglass Screen Fabric

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Good Quality Fiberglass fabric:

The Good Quality Fiberglass fabric is weaved of high quality C-glass fibers or E-glass fibers.

The Good Quality Fiberglass fabric is a good construction material with the following excellent properties:

* Dimensional stability

* High Strength

* Fire resistance, High heat resistance

* Good chemical resistance

* Durability

* Forms around complex surface shapes

Application of Good Quality Fiberglass fabric:

Fiberglass fabrics can be used in a variety of applications, including construction in waterproofing applications for roofing and foundation, wall treatment, pipeline joint wrap.

Packing of Good Quality Fiberglass fabric:

Fiberglass fabric is wound on a paper tube with inner diameters of 50. 8, 76 or 152mm. Each roll is wrapped in a plastic bag, then to be packed in a carton box. The rolls are to be horizontally placed.

Width (cm): 90, 100, 127

Length (m): 100, 200, 300, 400

Storage of Good Quality Fiberglass fabric:

Store rolls in a cool, dry location

Protect rolls from weather and other damage.

- Q: Can fiberglass fabric be used for tent or awning materials?

- Yes, fiberglass fabric can be used for tent or awning materials. It is a lightweight, durable, and weather-resistant material that can provide strength and stability to tents and awnings. Additionally, fiberglass fabric is known for its excellent thermal insulation properties, making it suitable for various outdoor applications.

- Q: Large screen whole electric lift screen, PVC good or glass fiber?

- If the effect of a long decline, it depends on how long the time is really down, both can not escape the fate of decline.

- Q: What are the different weights available for fiberglass fabric?

- Various weights of fiberglass fabric are available, typically measured in ounces per square yard (oz/yd²) or grams per square meter (g/m²). The weight of fiberglass fabric corresponds to its density or thickness, which can vary depending on the intended use and desired strength. There are several weight options commonly available for fiberglass fabric: - Lightweight option: 3 oz/yd² (102 g/m²). This option is suitable for applications where flexibility and ease of use are crucial, such as lightweight composite parts, surfboards, or small craft repairs. - Medium weight option: 5 oz/yd² (170 g/m²). This fabric provides a balance between flexibility and strength, making it suitable for boat building, automotive parts, and general fiberglass repairs. - Heavy weight option: 8 oz/yd² (272 g/m²). This fabric offers increased strength and durability, making it commonly used in applications that require higher impact resistance, such as the construction of industrial tanks, pipes, or structural reinforcements. - Heavyweight options: 10 oz/yd² (340 g/m²) and above. These options provide maximum strength and rigidity, making them ideal for demanding applications like aerospace, wind energy, or heavy-duty industrial equipment. When selecting the weight of fiberglass fabric, it is crucial to consider the specific requirements of your project. Factors such as the desired level of strength, flexibility, and the type of resin or adhesive being used should be taken into account to ensure that the fabric meets the necessary specifications.

- Q: Are there any specific certifications or standards for fiberglass fabrics?

- Yes, there are specific certifications and standards for fiberglass fabrics. One of the most widely recognized certifications for fiberglass fabrics is the ISO 9001:2015 certification, which signifies that the manufacturer has implemented a quality management system and meets the international standards for product quality. In addition, there are specific standards developed by organizations like ASTM International (formerly known as the American Society for Testing and Materials) that outline the testing methods and performance requirements for fiberglass fabrics. For example, ASTM D579-67(2013) provides standard specifications for glass fiber fabrics, while ASTM D3774-16a covers the testing of woven fabrics. Furthermore, there are industry-specific certifications that fiberglass fabric manufacturers may seek, such as the NORSOK M-710 certification for offshore applications or the MIL-STD-810 certification for military-grade fabrics. These certifications and standards help ensure that fiberglass fabrics meet certain quality, safety, and performance criteria. They provide customers with confidence in the product's reliability and help manufacturers demonstrate their commitment to producing high-quality fiberglass fabrics.

- Q: What are the different surface textures available in fiberglass fabric?

- Fiberglass fabric possesses a wide variety of surface textures, each with its own unique properties and advantages. Some examples of these textures include: 1. Plain Weave: This texture is the simplest and most commonly used, featuring a basic over-and-under pattern of fibers. It offers both strength and stability while providing a smooth surface finish. 2. Twill Weave: Twill weave consists of a diagonal pattern created by interlacing fibers. It offers enhanced drapability, better conformability, and increased strength compared to plain weave. Twill weave also provides a distinct appearance. 3. Satin Weave: Satin weave involves floating yarns over multiple warp or weft yarns, resulting in a smooth and lustrous surface. It offers exceptional flexibility, durability, and a high-quality finish. Satin weave is often employed in applications requiring a high level of aesthetics. 4. Leno Weave: Leno weave is characterized by a pair of warp yarns twisting around weft yarns, creating an open mesh structure. This texture improves breathability, facilitates resin saturation, and offers good drapability. Leno weave is commonly used in applications where air circulation or filtration is crucial. 5. Jacquard Weave: Jacquard weave involves intricate patterns created by individually controlling each warp yarn. It allows for the weaving of elaborate designs and textures into the fabric. Jacquard weave is frequently used for decorative purposes or when specific patterns are required. Each surface texture in fiberglass fabric is tailored to meet the specific requirements of various applications, including aerospace, automotive, marine, construction, and industrial sectors. The choice of texture depends on factors such as the desired strength, flexibility, aesthetics, and functionality needed for a particular application.

- Q: Can fiberglass fabrics be used for insulation in appliances?

- Indeed, fiberglass fabrics possess the capability to serve as insulation within appliances. These fabrics consist of interwoven glass fibers, which exhibit exceptional resistance to high temperatures and superb insulation qualities. They effectively capture and maintain heat, rendering them perfect for insulating appliances like ovens, stoves, and refrigerators. Moreover, fiberglass fabrics are lightweight, pliable, and simple to handle, enabling effortless installation in diverse appliance designs. Additionally, they boast durability and the ability to endure elevated temperatures without deteriorating or compromising their insulation properties. All in all, fiberglass fabrics represent a dependable and effective option for appliance insulation.

- Q: How is fiberglass fabric used in the chemical industry?

- Fiberglass fabric is commonly used in the chemical industry for a variety of purposes. It is utilized as a reinforcement material in the production of chemical storage tanks, pipes, and other equipment. The fabric's high strength and resistance to corrosion make it an ideal choice for protecting and containing various chemicals. Additionally, fiberglass fabric can be used as a lining material to prevent chemical leaks and spills, ensuring the safety and integrity of chemical processing systems.

- Q: Can fiberglass fabric be used for insulation in chemical plants?

- Fiberglass fabric, renowned for its exceptional thermal insulation properties, finds utility in chemical plants for insulation purposes. Its ability to withstand high temperatures, corrosion, and chemicals prevalent in such environments makes it an apt choice. Furthermore, its lightweight nature, ease of handling, and adaptability to diverse shapes and sizes make it ideal for insulating equipment, pipes, and tanks in chemical plants.

- Q: How does fiberglass fabric perform in creep resistance?

- Fiberglass fabric generally exhibits good creep resistance properties. Creep refers to the tendency of a material to deform slowly under a constant load or stress over time. Fiberglass fabric, due to its inherent structural composition and unique manufacturing process, possesses a high resistance to creep deformation. The use of glass fibers in the fabric provides excellent strength and stiffness, allowing it to withstand significant loads without experiencing permanent deformation. The fibers are tightly bound together in a matrix, typically made of epoxy or polyester resin, which further enhances the fabric's creep resistance. Moreover, the manufacturing process of fiberglass fabric involves a controlled heating and cooling cycle, known as curing, which effectively eliminates any residual stresses within the material. This eliminates the occurrence of creep caused by these internal stresses. Additionally, the epoxy or polyester resin matrix in fiberglass fabric acts as a protective layer, shielding the glass fibers from external environmental factors that may contribute to creep, such as moisture absorption or chemical degradation. Overall, fiberglass fabric is known for its excellent creep resistance, making it a suitable choice for applications that require structural stability and long-term performance under constant loads or stresses.

- Q: Can fiberglass fabric be used for reinforcement in sporting goods?

- Yes, fiberglass fabric can be used for reinforcement in sporting goods. Fiberglass fabric is known for its high strength-to-weight ratio, making it an ideal choice for reinforcing various sporting goods such as surfboards, kayaks, canoes, skis, and even hockey sticks. The fiberglass fabric is typically used in conjunction with epoxy resin to create a strong and durable composite material. The fabric is impregnated with resin and then layered onto the desired area, providing additional strength and stiffness to the sporting goods. This reinforcement helps to improve the overall performance and longevity of the product. Additionally, fiberglass fabric is corrosion-resistant, lightweight, and has excellent impact resistance, making it a popular choice for reinforcing sporting goods.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1969 |

| Annual Output Value | Above US$ 150 Million |

| Main Markets | overseas companies in Hongkong, Canada, South Africa, South Korea, India, Italy, Singapore, France and many other countries and regions. |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 5000,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Good Quality Fiberglass Screen Fabric

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords