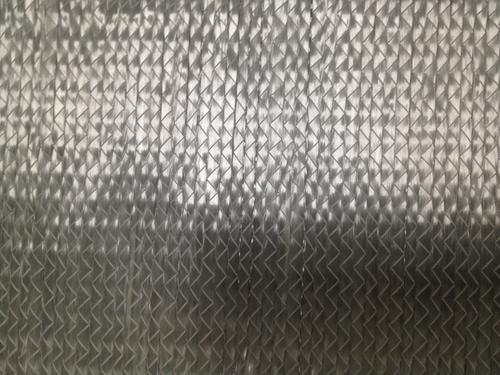

E-GLASS STITCH COMBO MAT- QX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction: E-glass stitched combo mat consists of two or more layers of fiberglass roving which are stitch-bonded.One layer of rovings and different layers of roving can be oriented differently and have different liner density.The roving specification,number of roving layers,mat width and roll diameter can be customized as per requirement. |

Multi-axial series: At most 4 layers of roving can be stitched;however a layer of chopped strands(0g/㎡-500g/㎡)or composite materials can be added.The maximal width can be too inched.This product is used in blades of wind power turbines,boat manufacturing and sports devices. |

Characteristics

1. Manufactured by own factory

2. Good wet-out in resins

3. Good strand dispersion and uniform area weight.

Specification

4 QX 0°/+45°/90°/-45° Quadraxial |

Product No. | Overall Density | 0°Roving Density(g/㎡) | +45°Roving Density (g/㎡) | 90°Roving Density(g/㎡) | -45°Roving Density(g/㎡) | Chop Density | Polyester Yarn Density(g/㎡) |

E-QX320 | 320.97 | 1.91 | 155.9 | 1.91 | 155.9 | - | 5.35 |

E-QX450 | 460.15 | 1.91 | 225.49 | 1.91 | 225.49 | - | 5.35 |

E-QX600 | 610.49 | 1.91 | 300.66 | 1.91 | 300.66 | - | 5.35 |

E-QX800 | 810.93 | 1.91 | 400.88 | 1.91 | 400.88 | - | 5.35 |

E-QX1000 | 1018.96 | 1.91 | 491.37 | 27.56 | 491.37 | - | 6.75 |

E-QX1150 | 1145.61 | 287.4 | 284 | 283.46 | 284 | - | 6.75 |

E-QX1200 | 1217.7 | 602.36 | 300.66 | 4.02 | 300.66 | - | 10 |

E-QXM620/98 | 722.33 | 15.75 | 300.66 | 1.91 | 300.66 | 98 | 5.35 |

E-QXM1300/128 | 1422.52 | 574.8 | 212.13 | 283.46 | 212.13 | 128 | 12 |

E-QXM1850/225 | 2104.06 | 472.44 | 467.69 | 462.99 | 467.69 | 225 | 8.25 |

FAQ

a.Pacage

Each Eglass stitched Combo Mat is wound onto a paper tube The roll is wrapped up with plastic film,and then packed in a cardboard box. The rolls can be vertically or horizontally placed. For transportation, the rolls can be loaded into a container directly or on pallets.

b.Product storage:

Unless otherwise specified, CHEMICAL FIBER GRIDDING CLOTH should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 50%~75% respectively.

- Q: Can fiberglass fabric be used for reinforcement in pipes and tanks?

- Indeed, pipes and tanks can benefit from the reinforcement offered by fiberglass fabric. This material boasts exceptional strength and durability, along with its ability to resist corrosion, rendering it an optimal selection for reinforcing structures that might endure severe chemicals or extreme temperatures. The fabric can be affixed to either the inner or outer surface of the pipe or tank, delivering enhanced stability and strength. Furthermore, fiberglass fabric offers the advantage of being lightweight and flexible, enabling it to conform effortlessly to the shape of the pipes or tanks, guaranteeing a reliable and efficient reinforcement.

- Q: Can fiberglass fabric be used for insulation in clean rooms?

- Fiberglass fabric, indeed, finds great utility in clean rooms as an insulation material. Renowned for its remarkable thermal and acoustic properties, it is commonly employed for insulation purposes. Its remarkable resistance to heat transfer and capacity to diminish noise render it ideal for establishing a controlled and insulated atmosphere within clean rooms. Furthermore, fiberglass fabric boasts qualities such as being lightweight, long-lasting, and impervious to chemicals and moisture, all of which are crucial factors to consider in clean room applications.

- Q: What are the different fiberglass fabric finishes for oil resistance?

- There are several different fiberglass fabric finishes that enhance oil resistance. One common finish is the silicone coating, which provides excellent resistance to oil and other hydrocarbons. This coating forms a barrier on the fabric, preventing oil from penetrating the fibers and causing damage. Another popular finish is the neoprene coating, which offers good resistance to oil, as well as other chemicals and solvents. Neoprene is a synthetic rubber that is highly resistant to oil degradation, making it an ideal choice for applications where oil resistance is crucial. Additionally, some fiberglass fabrics are treated with a fluoropolymer finish, such as PTFE (polytetrafluoroethylene). This finish provides exceptional resistance to oils, greases, and other chemicals. It forms a non-stick surface on the fabric, preventing oil from adhering and making it easier to clean. Furthermore, there are fiberglass fabrics with a proprietary oil-resistant coating that is specifically designed to withstand exposure to various types of oils, including mineral, vegetable, and synthetic oils. These coatings are typically formulated to provide long-lasting protection against oil degradation and are often used in demanding industrial applications. In summary, the different fiberglass fabric finishes for oil resistance include silicone coating, neoprene coating, fluoropolymer finish (such as PTFE), and proprietary oil-resistant coatings. These finishes offer varying degrees of oil resistance and are chosen based on the specific requirements of the application.

- Q: Is fiberglass fabric resistant to chemicals used in wastewater treatment?

- Fiberglass fabric exhibits remarkable resistance to the chemicals employed in wastewater treatment. Its outstanding chemical resistance has earned fiberglass a reputation as an optimal material for scenarios where exposure to diverse chemicals is probable. It has the capacity to endure a broad spectrum of corrosive substances, such as acids, alkalis, and solvents, commonly encountered in wastewater treatment processes. Due to the non-reactive quality of fiberglass fabric, it remains unaffected and undamaged when exposed to these chemicals, making it a dependable choice for implementation in wastewater treatment facilities. Additionally, fiberglass fabric also offers resistance to UV radiation, moisture, and fluctuations in temperature, which further bolsters its durability and suitability for such environments.

- Q: Are fiberglass fabrics resistant to staining or discoloration?

- Yes, fiberglass fabrics are generally resistant to staining or discoloration. This is because fiberglass is a synthetic material that is non-porous and does not absorb liquids or substances that can cause stains. Additionally, fiberglass fabrics are often treated with special coatings or finishes that provide an extra layer of protection against staining or discoloration. However, it is important to note that the level of resistance can vary depending on the specific type of fiberglass fabric and the substances it comes into contact with.

- Q: Can fiberglass fabric be used for reinforcement in pharmaceutical tanks?

- Certainly! Fiberglass fabric proves to be an effective reinforcement option for pharmaceutical tanks. Renowned for its impressive strength-to-weight ratio and exceptional resistance to corrosion, chemicals, and extreme temperatures, fiberglass fabric emerges as an optimal material choice for fortifying tanks used in the pharmaceutical sector. Given that these tanks frequently encounter various chemicals and substances, these inherent properties of fiberglass fabric enable it to provide structural support, enhance tank durability and longevity, and ensure compliance with required safety standards. Furthermore, the lightweight nature of fiberglass fabric simplifies its handling and installation in tank applications. In conclusion, employing fiberglass fabric as a reinforcement solution in pharmaceutical tanks guarantees a dependable and efficient choice.

- Q: How does fiberglass fabric perform in moisture resistance?

- Fiberglass fabric demonstrates a strong performance in terms of moisture resistance. It possesses a natural water-resistant quality and does not readily absorb moisture. This attribute renders it suitable for various applications that involve frequent exposure to moisture, including boat and yacht construction, outdoor furniture, and even the automotive industry. Furthermore, fiberglass fabric remains structurally sound and performs well even in high humidity conditions. Nevertheless, it is vital to acknowledge that while it resists moisture, it is not completely waterproof. Prolonged exposure to water or submersion may eventually result in some water absorption. Therefore, it is always advisable to refer to the specific product specifications and manufacturer guidelines to ascertain the level of moisture resistance offered by a particular fiberglass fabric.

- Q: Can I put up wall tiles on the bathroom wall waterproof cloth?

- With the coil, first clean the base, so that the base drying, and then roll on the ground, with the spray gun heating coil, is between the coil and coil gap bonding. But the material is relatively fragile, the surface is easy to break in when the gravel backfill and the pipeline root and Water Leakage, not very good treatment.

- Q: Can fiberglass fabrics be used for insulation in HVAC systems?

- Yes, fiberglass fabrics can be used for insulation in HVAC systems. Fiberglass is a popular choice for insulation in HVAC systems due to its excellent thermal properties. It has a low thermal conductivity, which means it can effectively resist heat transfer. Fiberglass fabrics are typically used to cover air ducts, pipes, and other components in HVAC systems to prevent heat loss or gain. Fiberglass fabrics also have other beneficial properties that make them suitable for insulation. They are lightweight, flexible, and easy to install, making them a convenient choice for HVAC insulation. Additionally, fiberglass fabrics are resistant to moisture, mold, and mildew, which helps in maintaining good indoor air quality. Furthermore, fiberglass fabrics have excellent fire-resistant properties. They are non-combustible and do not release toxic gases when exposed to high temperatures. This makes them a safe choice for insulation in HVAC systems. Overall, fiberglass fabrics can be effectively used for insulation in HVAC systems due to their thermal efficiency, ease of installation, moisture resistance, and fire safety.

- Q: Is fiberglass fabric resistant to rot and mildew?

- Indeed, the resistance of fiberglass fabric to rot and mildew is remarkable. This can be attributed to the composition of fiberglass, which consists of glass fibers and a polymer resin. This unique combination renders fiberglass highly impervious to moisture and fungal proliferation. Unlike natural textiles like cotton or wool, fiberglass fabric does not foster a conducive habitat for the growth of mold or mildew. Moreover, due to its non-porous nature, fiberglass does not absorb water, thereby further minimizing the likelihood of rot or mildew formation. Consequently, fiberglass fabric has gained significant popularity in various applications where moisture resistance and durability are paramount, such as outdoor furniture, boat covers, and automotive interiors.

Send your message to us

E-GLASS STITCH COMBO MAT- QX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords