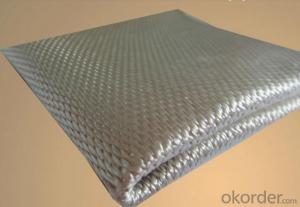

Fiberglass Fabrics Treated with Vermiculite

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Supply high temperature proof of texturized fiberglass yarn, tape, cloth, rope,fabrics with rubber coated, fiberglass Fabric Treated with Vermiculite.

(2)Fiberglass fabrics with silicone rubber coated:

Rubber coating fiberglass cloth is a fiberglass cloth, which possesses the properties of temperature resistance, anti-corrosion, high strength and made by rolling or impregnation with organic rubber. It is a newly made product with properties and many uses.

(3)high temperature proof fiberglass fabric like 3732 and 7628,HT800

It has: plain weave, twill weave, satin weave, gauze weave.

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines. Such as EW140, EW7628. 3732,

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth, such as EW3732, EW3784.

c) Satin weave: compared with plain weave and twill weave, it is of high density,high intensity, with a soft and loose structural weave with a good texture. It is applicable for use as a higher reinforced material in machinery, such as EW3784,EW3788.

d).Gauze weave: said lattice twist weave. It can be used in spread model curtain,resin reinforced emery wheel gray cloth and lattice embed belt.

Supply high temperature proof of fiberglass Fabric Treated with Vermiculite,,

- Q: Can fiberglass fabric be used for reinforcement in plastic parts?

- Indeed, reinforcement of plastic parts can be achieved through the utilization of fiberglass fabric. Renowned for its exceptional strength and durability, fiberglass fabric serves as an optimal selection for bolstering plastic components. By incorporating the fabric within the plastic material, it imparts enhanced resilience, rigidity, and resistance against deformation. This reinforcement proves particularly advantageous in situations requiring plastic parts to endure substantial loads, impacts, or extreme temperatures. Moreover, fiberglass fabric aids in improving the dimensional stability of plastic parts, consequently mitigating the likelihood of warping or distortion. Consequently, fiberglass fabric finds extensive application across various industries, effectively augmenting the mechanical properties and overall performance of plastic parts.

- Q: Can fiberglass fabric be used for making outdoor furniture?

- Yes, fiberglass fabric can be used for making outdoor furniture. Fiberglass is a durable and weather-resistant material that can withstand the elements, making it suitable for outdoor use. It is lightweight, yet strong, and can be molded into various shapes and forms, allowing for versatile design options. Additionally, fiberglass fabric is resistant to moisture, UV rays, and temperature changes, ensuring that the furniture will not warp, fade, or crack over time. Its low maintenance requirements and long lifespan make it an ideal choice for outdoor furniture, providing both functionality and aesthetics.

- Q: Are fiberglass fabrics resistant to mold or mildew?

- Yes, fiberglass fabrics are generally resistant to mold or mildew due to their non-porous nature and lack of organic materials that promote mold growth.

- Q: What type of thread is used for sewing fiberglass fabric?

- The type of thread typically used for sewing fiberglass fabric is a polyester thread.

- Q: How do fiberglass fabrics perform in terms of breathability for human comfort?

- For human comfort, fiberglass fabrics typically do not perform well in terms of breathability. This is due to their dense and tightly woven structure, which restricts the circulation of air. Consequently, efficient ventilation and airflow are not possible, causing discomfort and increased moisture accumulation on the skin. Moreover, fiberglass fabrics are commonly utilized in situations where thermal insulation is necessary, such as insulation materials or protective clothing. The insulation properties of fiberglass fabrics can confine heat and moisture, further diminishing breathability and potentially causing discomfort to the wearer. It is worth mentioning that there are alternative fabric choices available that offer superior breathability for human comfort. Natural fibers such as cotton, linen, and bamboo, as well as synthetic materials like polyester and nylon, are often favored for their ability to allow air to circulate more freely, thus keeping the body cool and dry. Therefore, if breathability and comfort are of utmost importance, it is advisable to consider fabrics other than fiberglass.

- Q: Can fiberglass fabric be used for making flexible hoses?

- Certainly! Flexible hoses can be made using fiberglass fabric. This material is renowned for its exceptional strength and flexibility, rendering it suitable for a wide range of purposes. Notably, it is commonly employed in the production of flexible hoses due to its unique attributes. By weaving the fabric into a flexible structure, it becomes capable of enduring bending, twisting, and stretching without compromising its integrity. Furthermore, fiberglass fabric exhibits resistance against high temperatures, chemicals, and abrasion. This outstanding feature makes it highly suitable for hoses that transport fluids, gases, and even solids. Given its durability and flexibility, it comes as no surprise that fiberglass fabric is extensively utilized in demanding industries such as automotive, aerospace, and construction, where hoses are constantly exposed to rigorous conditions.

- Q: Are fiberglass fabrics suitable for use in aerospace applications?

- Yes, fiberglass fabrics are suitable for use in aerospace applications. Fiberglass is a lightweight and high-strength material, which makes it ideal for aerospace applications where weight reduction is crucial. It has excellent mechanical properties, including high tensile strength, stiffness, and resistance to temperature variations, which are important for withstanding the extreme conditions experienced in aerospace environments. Fiberglass fabrics also have good electrical insulation properties, making them suitable for applications where protection against electromagnetic interference is necessary. Additionally, fiberglass fabrics can be engineered to be fire-resistant, further enhancing their suitability for aerospace applications. Overall, the combination of lightweight, high strength, temperature resistance, electrical insulation, and fire resistance makes fiberglass fabrics a reliable and suitable choice for use in aerospace applications.

- Q: How does fiberglass fabric handle vibration?

- The exceptional performance of fiberglass fabric in managing vibration is well-known. Its unique composition and structure grant it inherent properties that render it highly resistant to vibration. A significant factor that contributes to its ability to handle vibrations is its remarkable tensile strength. The process of weaving strands of fiberglass together to create this fabric produces a material that is sturdy and enduring. This elevated tensile strength allows the fabric to endure the forces exerted by vibrations without experiencing any deformation or damage. Furthermore, fiberglass fabric possesses a low density, making it lightweight and boasting a high strength-to-weight ratio. This quality enables the fabric to effectively dissipate vibrations and absorb energy, thereby minimizing the transmission of vibrations to the surrounding environment. Moreover, fiberglass fabric is renowned for its extraordinary dimensional stability. It retains its shape and structure even when subjected to dynamic conditions, which is crucial in applications prone to vibrations. This stability guarantees the fabric's integrity and functionality, preventing any detrimental effects on the overall system's performance. In conclusion, fiberglass fabric is a reliable and efficient material for vibration management. Its high tensile strength, low density, and dimensional stability render it an ideal choice for numerous industries and applications where vibration control is imperative.

- Q: How to deal with cracks in floor construction joints?

- The width of the fracture shall not be treated within the design allowable range. When the crack width exceeds the standard requirement, the cause of cracking shall be determined first, and then treated after the development of the fracture is basically stable. If the cracks affecting the structure safety, should be addressed to the design or management department.

- Q: Can fiberglass fabric be used for flags?

- Yes, fiberglass fabric can be used for flags.

Send your message to us

Fiberglass Fabrics Treated with Vermiculite

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords