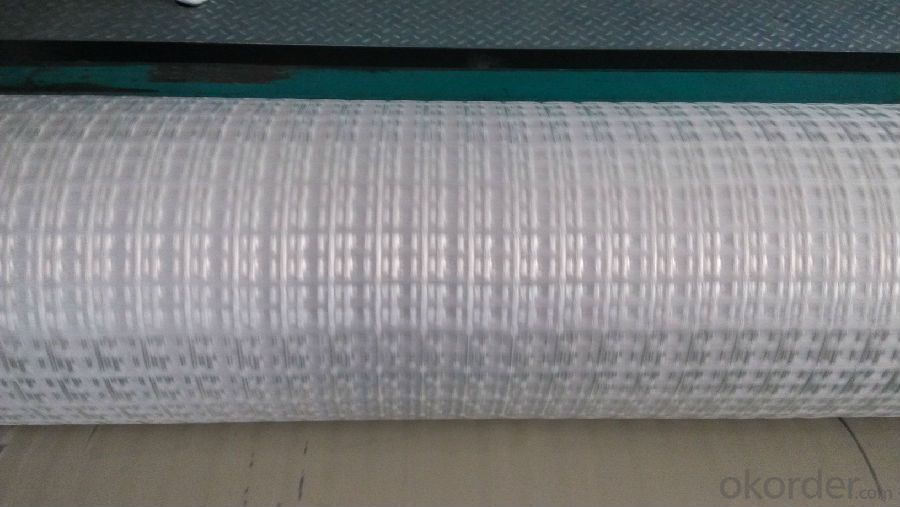

Teflon Coated Fiberglass Fabric Roof - High Quality Fiberglass Geogrid for Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Product has high strength, low elongation, high temperature, high modulus , light weight , good toughness, corrosion resistance , long life , etc. , can be widely used in the old concrete pavement , maintenance of airport runways , dams , river banks , while slope protection , road bridge , enhancement engineering field, to the road surface can be enhanced , reinforced to prevent pavement rutting fatigue crack , hot and cold telescopic cracks and reflection cracks below , and can the pavement load stress dispersion , extending pavement life .

2.Characteristics

The high tensile strength low - elongation : Fiberglass geogrid is a glass fiber , while the high tensile strength of glass fiber , more than other fibers and ordinary metals . Its high modulus , high resistance to deformation , elongation at break of less than 3% .

3.Application

Physical and chemical stability after special treatment agent coated handle , fiberglass geogrid to resist a variety of physical wear and chemical attack , but also to resist biological erosion and climate change to ensure that its performance is unaffected by the loss .

5.FAQ

Good thermal stability : the melting point of glass fibers is above 1000 °C , to ensure the stability of the glass fiber geogrids to withstand high temperature in a paving job .

- Q: Can fiberglass fabrics be used for reinforcement in architectural structures?

- Yes, fiberglass fabrics can be used for reinforcement in architectural structures. Fiberglass is a strong and lightweight material that has high tensile strength and excellent resistance to corrosion, making it ideal for reinforcing various architectural elements. It is often used in the construction industry to reinforce concrete structures such as walls, beams, and columns. Fiberglass fabrics can be embedded into concrete to increase its strength and durability, providing additional support and reducing the risk of cracking or structural failure. Additionally, fiberglass fabrics are flexible and can be easily molded or shaped to fit different architectural designs and structures. Overall, fiberglass fabrics are a versatile and reliable choice for reinforcement in architectural structures.

- Q: Are there any specific installation instructions for fiberglass fabrics?

- Fiberglass fabrics come with specific installation instructions that must be followed to ensure proper installation and maximize their effectiveness. To help you with the process, here are some general guidelines to consider: 1. Properly prepare the surface before installing fiberglass fabrics. Make sure it is clean, dry, and free from debris, dust, or contaminants that could affect the fabric's adhesion. 2. Choose an appropriate adhesive that is compatible with both the fiberglass fabric and the surface you are working on. Consult the manufacturer's recommendations to select the best adhesive for your specific application. 3. Measure and cut the fiberglass fabric according to the desired dimensions, ensuring it provides sufficient coverage for the intended area. Use sharp scissors or a utility knife for clean and precise cuts. 4. Apply a thin and even layer of the chosen adhesive onto the prepared surface using a brush, roller, or trowel. Follow the manufacturer's instructions regarding application and drying times. 5. Carefully place the cut fiberglass fabric onto the adhesive-coated surface, avoiding stretching or wrinkling. Smooth out any air bubbles or creases using a roller or squeegee to ensure proper adhesion. 6. If necessary, apply additional layers of fiberglass fabric, overlapping the edges by a few inches to ensure a seamless and durable installation. Follow the same adhesive application procedure for each layer. 7. Allow sufficient time for the adhesive to cure and the fiberglass fabric to bond securely to the surface. The curing time may vary depending on the adhesive type and environmental conditions. Refer to the manufacturer's instructions for the recommended curing time. 8. Once the adhesive is fully cured, trim any excess fiberglass fabric using a sharp utility knife. Sand down any rough edges or uneven surfaces for a smooth finish. Always refer to the manufacturer's instructions for the specific fiberglass fabric and adhesive you are using, as different products may have unique installation requirements. If you are unsure or uncomfortable with the installation process, it is recommended to seek professional assistance to ensure a successful and safe installation.

- Q: Can fiberglass fabric be used for reinforcement in architectural structures?

- Yes, fiberglass fabric can be used for reinforcement in architectural structures. It is a lightweight material that offers high strength and durability, making it suitable for reinforcing concrete, masonry, and other building materials. Fiberglass fabric is commonly used in applications such as wall panels, roofing systems, and composite structures, providing added structural support and enhancing the overall strength and stability of architectural designs.

- Q: Can fiberglass fabric be used in low-temperature applications?

- Indeed, low-temperature applications can make use of fiberglass fabric. This material is renowned for its remarkable thermal insulation characteristics, rendering it appropriate for deployment in low-temperature surroundings. It is frequently utilized in various scenarios, including cryogenic insulation, cold storage facilities, and refrigeration systems. The fabric itself possesses a diminished thermal conductivity and can endure exceedingly low temperatures without compromising its structural integrity. Moreover, it exhibits resilience against moisture, chemicals, and UV radiation, thereby establishing itself as a dependable and long-lasting option for low-temperature applications.

- Q: Can fiberglass fabric be used for reinforcement in water treatment tanks?

- Indeed, water treatment tanks can benefit from the utilization of fiberglass fabric as a reinforcement. With its exceptional strength and durability, fiberglass emerges as an ideal material that exhibits resistance towards corrosion and chemicals, rendering it highly suitable for water treatment purposes. By offering structural reinforcement to the tanks, fiberglass guarantees their stability and longevity. Furthermore, the lightweight nature of fiberglass fabric facilitates easy installation, making it a cost-effective solution for reinforcing water treatment tanks.

- Q: Can fiberglass fabric be used for insulation in industrial equipment?

- Yes, fiberglass fabric can be used for insulation in industrial equipment. Fiberglass fabric is a versatile material that offers excellent thermal insulation properties. It is lightweight, non-combustible, and resistant to heat, chemicals, and moisture. These characteristics make it ideal for insulating industrial equipment such as boilers, furnaces, tanks, and pipes. Fiberglass fabric can effectively minimize heat transfer, reduce energy loss, and maintain stable temperatures in industrial processes. Additionally, it is easy to install, durable, and has a long lifespan, making it a cost-effective insulation solution for industrial applications.

- Q: How does fiberglass fabric perform in water repellency?

- Fiberglass fabric is not inherently water repellent. However, it can be treated with various coatings or finishes to enhance its water repellency.

- Q: What are the different widths available for fiberglass fabric rolls?

- Fiberglass fabric rolls typically come in various widths to accommodate different applications and preferences. The available widths can vary depending on the manufacturer, but some common options include 1 inch, 2 inches, 3 inches, 4 inches, 6 inches, 12 inches, and 24 inches. These widths are designed to provide flexibility and versatility for a range of projects, from small repairs and patching to larger-scale applications such as boat construction or automotive repairs. It is important to check with the specific supplier or manufacturer to determine the exact widths available for fiberglass fabric rolls, as they may offer additional or customized options to cater to specific needs.

- Q: What is fiberglass sound absorption board?

- Glass wool is the molten glass fibrosis, the formation of cotton like material, chemical composition of glass, is a kind of inorganic fibers. With good forming, small volume density, thermal conductivity, both thermal insulation, sound-absorbing performance, corrosion resistance, chemical stability.

- Q: Is fiberglass fabric resistant to aging or deterioration?

- Yes, fiberglass fabric is highly resistant to aging and deterioration. Its durable nature allows it to maintain its strength and structural integrity over time, making it a reliable option for various applications.

Send your message to us

Teflon Coated Fiberglass Fabric Roof - High Quality Fiberglass Geogrid for Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords