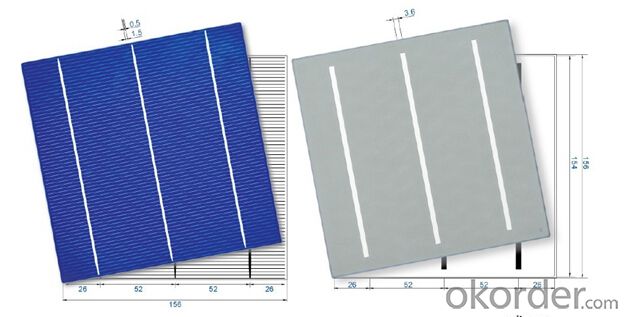

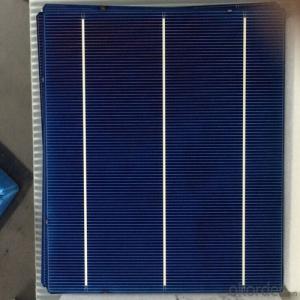

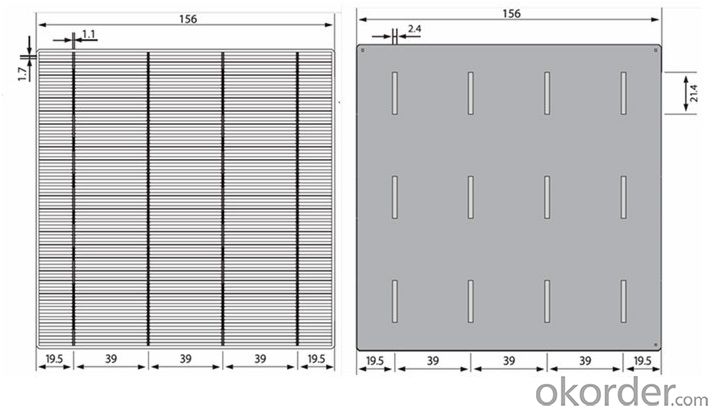

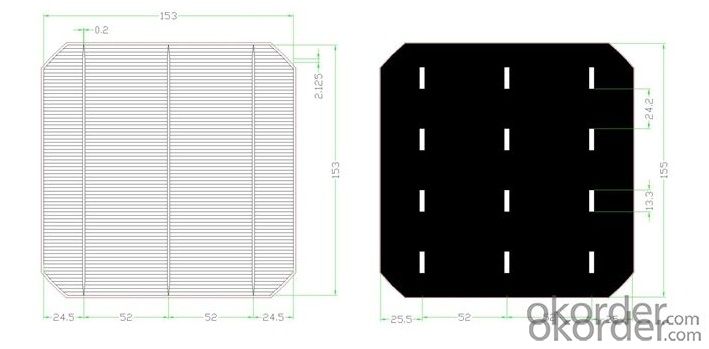

Silicon Wafer Solar Grade A 156x156mm Poly Stable Quality Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Grade A 156x156mm Poly Stable Quality Solar Cell

Solar Module Summarize

Solar Module is the core part of solar PV power systems,also is the highest value part of it. The function of Solor Module is to convert the sun's radiation to electrical energy, or transfer it to battery and store in it, or to drive the load running.

The Product has been widely used in space and ground, it mainly used for power generation systems, charging systems, road lighting and traffic signs areas. It could offer a wide range of power and voltage, and with high conversion efficiency, and long service life.

Solar Module Specifications

Mono 80W—100W

Module | Type (36 Series) | |||||

Encapsulation | Glass/EVA/Cells/EVA/TPT | |||||

Parameters | SNM-M80(36) | SNM-M85(36) | SNM-M90(36) | SNM-M95(36) | SNM-M100(36) | |

Max power | Pm(W) | 80W | 85W | 90W | 95W | 100W |

Tolerance | +/-3% | |||||

Open circuit voltage | Voc(V) | 21.2 | 21.8 | 21.8 | 22.3 | 22.6 |

Short circuit current | Isc(A) | 4.84 | 5.00 | 5.30 | 5.44 | 5.68 |

Max. power voltage | Vmp(V) | 17.5 | 18.0 | 18.0 | 18.5 | 18.5 |

Max. power current | Imp(A) | 4.57 | 4.72 | 5.00 | 5.14 | 5.40 |

Dimensions | (L*W*H) | 1200x540x35mm | ||||

Net Weight | (kg) | 9 | ||||

Max. system voltage | (V) | 1000VDC | ||||

Operate Temp. Scope | -40/+85'C | |||||

Resistance | 227g steel ball fall down from 1m height and 120m/s wind | |||||

Warranty | Pm is no less 90% in 10 years and no less 80% in 25 years | |||||

STC | (Standard Test Condition: 1000W/m2, AM1.5, and 25'C) | |||||

Picture show

- Q: How are solar silicon wafers protected from damage during transportation?

- Solar silicon wafers are typically protected from damage during transportation through the use of specialized packaging materials and handling procedures. These wafers are often enclosed in anti-static and shock-absorbing packaging materials such as foam or bubble wrap to prevent any impact or vibration-related damage. Additionally, they are typically stored in sturdy containers or crates to ensure safe transportation and minimize the risk of breakage.

- Q: Can solar silicon wafers be used in solar water heating systems?

- Yes, solar silicon wafers can be used in solar water heating systems. These wafers are typically used in the production of photovoltaic (PV) solar panels, which convert sunlight into electricity. However, in solar water heating systems, the solar silicon wafers are used to capture the sun's heat to directly heat water.

- Q: 1 megawatts of solar energy need how many wafers

- It depends on whether it is a single crystal or polycrystalline, I only know that polycrystalline is about 3.8 mw.

- Q: Can solar silicon wafers be used in portable charging devices?

- Yes, solar silicon wafers can be used in portable charging devices. These wafers are commonly used in the production of solar panels, which convert sunlight into electricity. By incorporating solar silicon wafers into portable charging devices, such as solar-powered chargers or power banks, it is possible to harness solar energy and use it to charge various electronic devices on the go.

- Q: What are the advantages of using a solar silicon wafer in solar cells?

- Using a solar silicon wafer in solar cells offers several advantages. Firstly, silicon is abundant and readily available, making it cost-effective for mass production. Secondly, silicon has excellent electrical properties, allowing for efficient conversion of sunlight into usable electricity. Additionally, silicon is durable and has a long lifespan, ensuring the longevity of solar cells. Furthermore, silicon wafers can be easily customized and integrated into various sizes and shapes, providing flexibility in design and application. Overall, the use of solar silicon wafers in solar cells contributes to sustainable energy production, affordability, efficiency, and versatility.

- Q: How long does it take to produce a solar silicon wafer?

- The production of a solar silicon wafer typically takes around 2-3 weeks from start to finish.

- Q: What is the typical voltage output of a solar silicon wafer?

- The typical voltage output of a solar silicon wafer can range from 0.5 to 0.6 volts.

- Q: How is a junction box sealant applied to a solar silicon wafer?

- A junction box sealant is typically applied to a solar silicon wafer by using a dispensing tool or equipment. The sealant is carefully dispensed or applied onto the junction box area of the wafer, ensuring a proper and uniform coverage. The application process is usually carried out in a controlled environment to maintain the integrity and quality of the sealant.

- Q: How long do solar silicon wafers last in a solar panel?

- Solar silicon wafers can last for several decades in a solar panel, typically around 25 to 30 years.

- Q: Can solar silicon wafers be used in solar-powered telecommunications?

- Yes, solar silicon wafers can be used in solar-powered telecommunications. These wafers are commonly used in the production of photovoltaic cells, which convert sunlight into electricity. Since solar-powered telecommunications systems rely on harnessing solar energy to power their operations, solar silicon wafers are an essential component in the generation of electricity from sunlight.

Send your message to us

Silicon Wafer Solar Grade A 156x156mm Poly Stable Quality Solar Cell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 watt

- Supply Capability:

- 10000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches