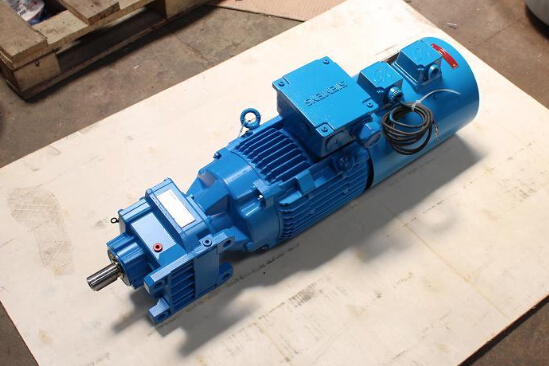

Siemens Reducer Gear Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: As soon as I turn off the heat, the whistling sound dissapears

- it is probably the bearing in the fan motor or some debris that has worked it's way in there. worry about it when the noise is constant. it

- Q: How can i setup regenerative braking on an AC motor?

- electric powered locomotives can feed their braking ability lower back into the overhead wires (as long as there is yet another prepare interior the device to consume the potential). In a diesel-electric powered locomotive you do not have everywhere to place the extra potential (different than slightly for prepare heating/air-conditioning on passenger trains), so which you in lots of instances warmth up resistor banks with the electrical powered ability from the vehicles, even however this permits you to't re-use the potential. you may fee a battery and use that ability lower back to strengthen up the prepare later, then you rather had a hybrid locomotive, i've got self assurance they are sorting out that for the period of a few shunters yet there's no great scale application yet. yet another a danger answer for short term potential storage could be flywheels. In a diesel-hydraulic engine you will have a retarder (to boot to friction brakes) which will warmth up oil while braking.

- Q: What is AC used for as is without being rectified into DC first, if anything?

- AC is the simplest way to distribute electricity, especially over long distances. If DC is needed, as in electronics, the AC is easily rectified. The vast majority of motor driven appliances have AC motors, and heating elements (stoves, water heaters etc.), work directly on AC just like they would on DC.

- Q: I have never seen such a motor with 3, 5, 7 poles etc. - always an even number. Why? Physically impossible?

- I don't know of any induction motor with an odd number pof poles.Refer to www. 3-phase motors.

- Q: My AC was doing great these past couple of days, the unit appears to be older. maybe 10-15 years? Anyway, last night and today, if you turn in on, you hear a light whirring, but the fan is not moving, and there is no cold air coming into the house. The HVAC itself is working fine by the way. Any thoughts or suggestions.

- Contact the local HVAC service center and have them do a service on the unit. If it is just a fan motor problem the diagnosis should take less than an hour then the RR will depend on the parts needed. Without the training to do the work you are just using AWAG about the system and it's problems.

- Q: It is the chiller plant pump and we were trying to run the pump,unfortunately the motor was damaged.so what could have happened to this motor.

- If the motor is filled with water, don't run it. Disassemble the motor and oven bake until the moisture is evaporated. If the motor is immersed while operating, the motor may be burnt. Megger test between line to ground and between two lines. If the insulation resistance is below 1 megohm, the motor may be burnt.

- Q: ac motor tripping on single phase cause?

- Motor overloaded, or very low voltage applied (such as using an extension cord with wiring that is too small).

- Q: How to speed the AC motor?

- The speed of three-phase asynchronous motor is expressed as:N= (60 * f / P) * (1s) =n1 (1s),N - motor speed (R / min, revolutions per minute); F - power frequency (Hz);P - the polar logarithm of an electric motor;S - slip ratio of motor, s= (N1 - n) / n;Synchronous speed n1 motor, n1= (60 * f / P) (R / min).There is a way to change the speed of an electric motor:1, change the power frequency;2, change the number of poles of the motor;3, change the speed difference.

- Q: My motor draws 24VDC / 5A and runs off a lead acid battery. If I input 120VAC / 15A in a ACgt;DC power supply what does it out have to be to run the motor? I've been told an output of 24VDC / 5A is not enough.

- You were told right. Motors can draw more that rated current on start-up and when loaded down and power supply ratings are for resistive loads, which your motor isn't. I like to have a power supply with double the motor's running current if I can, or 10 amps. It will only take 2 amps 120VAC into the supply to get that much DC, so you're OK there.

- Q: When the ac is on all lights dim (dashboard and headlights). All other functions slow down (wiper, windows and power antenna). Engine runs great when ac is off - no overheating.

- Check to make sure ac pulley is spinning and or that your fans kick on

Send your message to us

Siemens Reducer Gear Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords