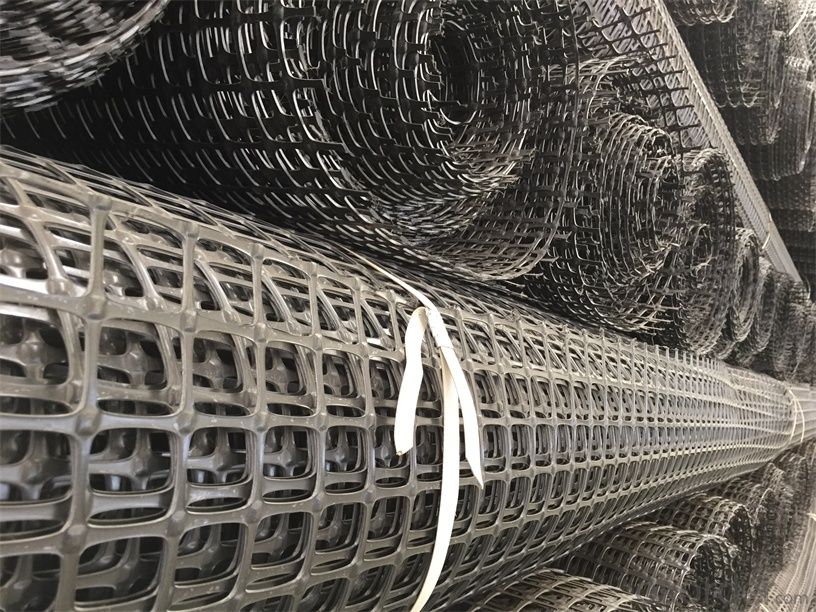

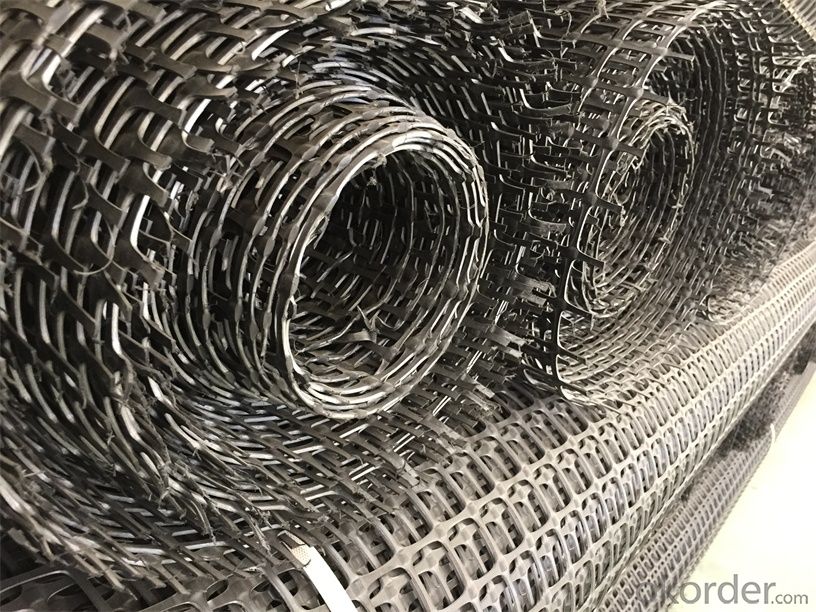

High Tensile Strength Polyester Geogrids Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: Can geogrids be used in stabilization of riverbanks?

- Yes, geogrids can be used in the stabilization of riverbanks. Geogrids are commonly utilized in civil engineering and geotechnical applications to reinforce soil and prevent erosion. By providing additional strength and stability to the riverbank, geogrids help to prevent soil erosion, reduce sedimentation, and protect against damage caused by water flow, ultimately enhancing the stability and longevity of the riverbank.

- Q: How do geogrids enhance the performance of geotextile tubes?

- Geogrids enhance the performance of geotextile tubes by providing additional strength and stability. They act as a reinforcement layer within the tube, preventing deformation and maintaining the desired shape. Geogrids also help distribute the load evenly, increasing the overall stability and durability of the geotextile tube system.

- Q: Evaluation criteria and technical disclosure of geogrid.. Know how to share. Thank you

- 2) according to the design of the location, along the road to the laying of the grid, laying the grille, should pay attention to the connection between the grid and straightening smooth. Grille of the longitudinal and transverse joints can use nylon or polyester rope sewn or U nail connection method between the grid as a whole, grid overlapping width not less than 20cm, in the direction of the stress intensity of the joint shall not be less than the design tensile strength of materials. The grid distortion, fold, overlap, is not conducive to play its role, thus laying by hands straightened, the grid is smooth and uniform, geogrid every 1.5-2.0m paved with hook nail fixed on the ground.

- Q: Can geogrids be used in green wall systems?

- Yes, geogrids can be used in green wall systems. Geogrids provide stability and reinforcement to the structure, helping to support the weight of the green wall system and prevent soil erosion. They can be used to create a strong foundation and provide additional support for the plants, ensuring the success and longevity of the green wall.

- Q: Which instrument is used to measure the permeability of geotextiles?

- Is made of filament or staple through the equipment and technology of different laying into the mesh, after acupuncture process for different fiber intertwined intertwined fixing fabric specification, make the fabric soft, plump, thick, stiff, to achieve different thickness to meet the requirement of use

- Q: What are the specifications of the geogrid for road use?

- Warp knitted grating

- Q: How do geogrids enhance the performance of geosynthetic clay liner capillary barriers?

- Geogrids enhance the performance of geosynthetic clay liner capillary barriers by providing additional reinforcement and stability to the liner system. They help to distribute and reduce the load on the clay liner, preventing its deformation and maintaining its integrity. The geogrids also improve the shear strength and tensile properties of the clay liner, enhancing its ability to resist cracking and maintain its barrier function against water or other fluids. Overall, the presence of geogrids enhances the long-term performance and durability of geosynthetic clay liner capillary barriers.

- Q: Are geogrids resistant to fire?

- No, geogrids are not typically resistant to fire. They are primarily used for soil stabilization and reinforcement purposes and do not possess inherent fire-resistant properties.

- Q: What are the long-term durability characteristics of geogrids?

- Geogrids have excellent long-term durability characteristics. They are designed to withstand harsh environmental conditions, including high temperatures, moisture, and chemical exposure. Geogrids are made from high-strength materials, such as polyester or polypropylene, which provide resistance against degradation and maintain their structural integrity over time. They have a long service life and can effectively retain soil, stabilize slopes, and reinforce paved surfaces for many years without significant deterioration.

- Q: Can geogrids be used in ground stabilization for water treatment plants?

- Yes, geogrids can be used in ground stabilization for water treatment plants. Geogrids are commonly used in civil engineering projects to improve the stability and load-bearing capacity of soil. In the case of water treatment plants, geogrids can help prevent soil erosion, reinforce embankments, and provide stability to the ground, ensuring the safe and long-lasting operation of the facility.

Send your message to us

High Tensile Strength Polyester Geogrids Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords