Shaft-Platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

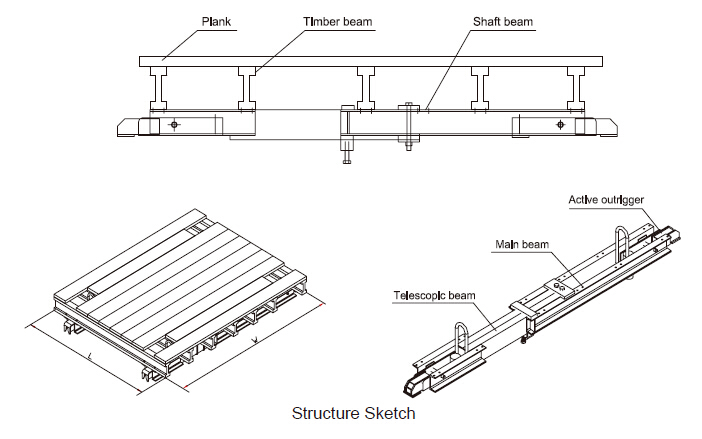

Shaft Platform

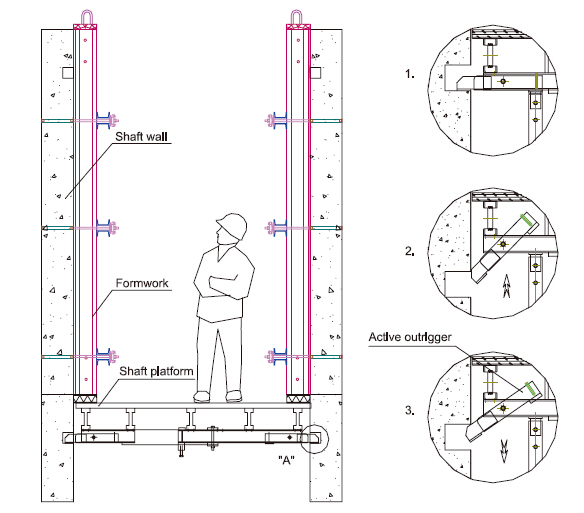

As operating platform, the shaft platform is mainly used in the concrete pouring of elevator shaft,

equipment shaft, stair shaft of high-rise building and so on.

Characteristics:

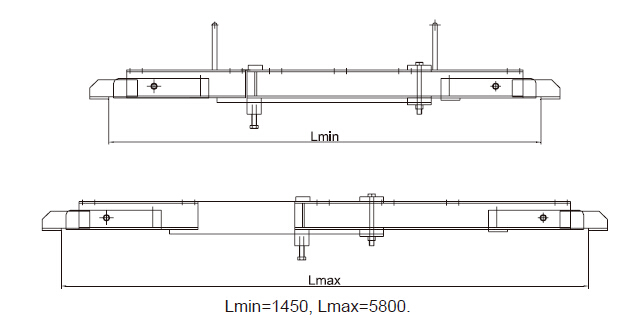

◆ The length of shaft beam is adjustable.

◆ Flexible structure makes lifting easier.

- Q: How is steel formwork constructed?

- To construct steel formwork, a systematic process with multiple steps is followed. Initially, the dimensions and requirements of the concrete structure are determined, taking into consideration its shape, size, and design. Once the dimensions are finalized, steel sheets are cut to the required sizes and shapes. These sheets are then assembled and connected using various methods such as welding or bolting, depending on the design and strength requirements. The connections between the steel sheets are crucial to maintain stability and rigidity of the formwork. After assembling the steel sheets, additional components like stiffeners, braces, and beams are incorporated to provide structural support and reinforcement to the formwork. These components help distribute the load evenly and prevent any deformation during the pouring and curing of concrete. Once the formwork structure is fully assembled and reinforced, it is positioned and secured to the ground or existing structures using anchors or supports. This ensures the formwork remains stable and in place during the concrete pouring process. The final step involves waterproofing the steel formwork to prevent any water leakage or seepage from the concrete. This is typically achieved by applying a waterproofing membrane or coating to the inner surface of the formwork. Overall, constructing steel formwork demands meticulous planning, precise cutting, accurate assembly, and proper reinforcement. Adherence to industry standards and guidelines is crucial to ensure the structural integrity and safety of the formwork system.

- Q: Can steel formwork be used in marine construction projects?

- Yes, steel formwork can be used in marine construction projects. Steel formwork is a durable and versatile construction material that can withstand the harsh conditions of marine environments such as saltwater, waves, and corrosion. It is often used in marine construction projects for various applications such as building piers, docks, seawalls, and other structures that require a strong and stable foundation. Steel formwork provides excellent structural support and can withstand the heavy loads and pressures associated with marine construction. Additionally, steel formwork can be easily assembled and disassembled, making it a practical choice for marine construction projects where time and efficiency are crucial. Overall, steel formwork is a reliable and suitable option for marine construction projects.

- Q: Can steel formwork be used for railway construction projects?

- Yes, steel formwork can be used for railway construction projects. Steel formwork is a highly durable and versatile material that can withstand the heavy loads and pressures associated with railway construction. It provides a strong and rigid structure for pouring concrete and shaping the desired forms for railway infrastructure, such as tunnels, bridges, platforms, and retaining walls. Steel formwork offers several advantages for railway construction projects. Firstly, it has a high load-bearing capacity, allowing it to support the weight of the concrete and any additional loads. This is particularly important in railway construction, where safety and stability are paramount. Secondly, steel formwork is reusable, making it a cost-effective choice for large-scale projects. It can be easily dismantled, cleaned, and reassembled for future use, reducing the need for additional formwork materials and minimizing waste. Furthermore, steel formwork provides excellent dimensional accuracy and surface finish. It ensures that the concrete structures produced are of high quality and meet the required specifications and standards for railway construction. Additionally, steel formwork is highly resistant to moisture, chemicals, and other environmental factors that can degrade the formwork material. This makes it suitable for both indoor and outdoor railway construction projects, where exposure to harsh weather conditions is common. Overall, steel formwork is a reliable and efficient choice for railway construction projects. Its strength, reusability, dimensional accuracy, and resistance to environmental factors make it an ideal material for shaping and pouring concrete structures in railway infrastructure development.

- Q: Is steel formwork suitable for projects with limited access?

- Projects with limited access can benefit from the use of steel formwork. Steel formwork is renowned for its strength and durability, enabling it to withstand the challenges posed by restricted access. This type of formwork can be conveniently transported and assembled in confined spaces, making it an ideal choice for projects with restricted access. Moreover, the ease with which it can be dismantled and reused is advantageous in situations where efficient transportation of materials is necessary. The versatility and adaptability of steel formwork render it a suitable option for projects that have limited access.

- Q: How does steel formwork contribute to improved construction efficiency?

- Improved construction efficiency can be achieved through the use of steel formwork, which offers various advantages. To begin with, steel formwork stands out for its durability and strength. It has the ability to withstand heavy loads and extreme weather conditions, enabling construction projects to proceed without interruptions. As a result, builders can work more quickly and efficiently. Furthermore, steel formwork is reusable, unlike traditional timber formwork that often needs to be replaced after a few uses. This reduces the need for constant material replenishment, saving time, cutting down on construction costs, and minimizing waste. Moreover, steel formwork provides excellent dimensional accuracy and stability. It allows for precise shaping and alignment of concrete structures, guaranteeing that they meet the required specifications and standards. This accuracy eliminates the need for rework or adjustments, saving time and resources. In addition, steel formwork is easy to assemble and dismantle due to its modular design. This facilitates quick installation and removal, reducing the time spent on formwork-related activities. This aspect is particularly advantageous for large-scale projects where time is of the essence. Furthermore, steel formwork produces a smooth and even finish on concrete structures, eliminating the need for additional plastering or finishing work. This further enhances construction efficiency. Additionally, the smooth surfaces created by steel formwork are easier to clean and maintain, ensuring a longer lifespan for the structure. Lastly, steel formwork enhances the safety of construction workers. Its strength and stability minimize the risk of accidents or collapses, creating a secure working environment. This, in turn, boosts productivity and efficiency on the construction site. To summarize, the use of steel formwork improves construction efficiency by providing durability, reusability, dimensional accuracy, quick assembly, smooth finishes, and enhanced safety. These factors allow construction projects to progress more rapidly, reduce costs, and deliver high-quality structures within the desired timeframe.

- Q: What are the different types of formwork corners used in steel formwork systems?

- In steel formwork systems, there are several types of formwork corners used to create different shapes and angles in the construction process. These corners are designed to provide stability, support, and flexibility in forming concrete structures. Some common types of formwork corners used in steel formwork systems are: 1. External 90-Degree Corner: This type of corner is used to create a right angle or 90-degree corner in the formwork. It is typically made of steel plates and angles that are connected and reinforced to provide strength and stability. External 90-degree corners are commonly used in building walls, columns, and beams. 2. Internal 90-Degree Corner: Similar to the external 90-degree corner, the internal 90-degree corner is used to create a right angle or 90-degree corner in the formwork. However, it is designed to be placed inside the formwork, providing a smooth finish on the exposed concrete surface. Internal 90-degree corners are commonly used in walls, columns, and other structures where a clean finish is desired. 3. Adjustable Corner: An adjustable corner is used when there is a need for different angles and shapes in the formwork. It consists of adjustable steel plates and angles that can be positioned and locked into place to create the desired shape and angle. Adjustable corners are versatile and can be used for various applications such as curved walls, sloping structures, and irregular shapes. 4. Chamfered Corner: A chamfered corner is used to create a beveled or chamfered edge on the concrete structure. It is typically made of steel plates and angles that are positioned to form a specific angle or bevel. Chamfered corners are commonly used in architectural applications to create decorative edges, enhance the appearance of the structure, and provide a smooth transition between different elements. 5. Rounded Corner: A rounded corner is used to create a curved or rounded edge in the concrete structure. It is typically made of steel plates and angles that are bent or shaped to form the desired curve or radius. Rounded corners are commonly used in architectural applications, such as curved walls, arches, and other curved elements, to create a visually appealing and unique design. These are just a few examples of the different types of formwork corners used in steel formwork systems. The specific type of corner used will depend on the desired shape, angle, and finish of the concrete structure being formed. It is important to select the appropriate formwork corner to ensure the integrity and quality of the construction project.

- Q: What are the different safety certifications and standards for steel formwork?

- There are several safety certifications and standards that apply to steel formwork. These certifications and standards ensure that the steel formwork meets specific safety requirements and can be used safely in construction projects. Some of the different safety certifications and standards for steel formwork include: 1. ISO 9001: This certification ensures that the steel formwork manufacturer has implemented a quality management system and meets the necessary quality standards. It focuses on the overall quality and reliability of the product. 2. ISO 3834: This certification ensures that the welding processes used in the production of steel formwork are carried out in accordance with specific quality requirements. It emphasizes the welding quality and ensures that the welds are strong and durable. 3. EN 12812: This European standard provides guidelines for the design and performance of formwork systems, including steel formwork. It covers aspects such as load-bearing capacity, stability, and safety requirements for formwork systems. 4. OSHA: The Occupational Safety and Health Administration sets safety standards for the construction industry in the United States. While there are no specific certifications for steel formwork, compliance with OSHA standards is essential to ensure a safe working environment for construction workers using steel formwork. 5. BS 5975: This British standard provides recommendations for temporary works, including formwork systems. It covers aspects such as design, erection, use, and dismantling of formwork systems, ensuring safety throughout the construction process. 6. ACI 347: This American Concrete Institute standard provides guidelines for the design, construction, and maintenance of concrete structures. It includes recommendations for formwork systems, including steel formwork, to ensure their safety and effectiveness in supporting the concrete during construction. These certifications and standards play a crucial role in ensuring that steel formwork is manufactured and used safely in construction projects. By adhering to these certifications and standards, construction companies can ensure the safety of their workers and the quality of their structures. It is important for construction professionals to be aware of these certifications and standards and ensure compliance with them when using steel formwork.

- Q: How does steel formwork compare to aluminum formwork in terms of cost?

- Steel formwork generally tends to be more cost-effective compared to aluminum formwork. This is primarily due to the fact that steel is a cheaper material than aluminum. Additionally, steel formwork is known for its durability and long lifespan, which further reduces overall costs in the long run. On the other hand, aluminum formwork may have a higher initial cost but is lighter in weight, making it easier to handle and transport.

- Q: What are the common safety measures to be followed when using steel formwork?

- Some common safety measures to be followed when using steel formwork include: 1. Proper training: Ensure that all workers using steel formwork are properly trained on its installation, dismantling, and usage procedures. 2. Personal protective equipment (PPE): Workers should wear the appropriate PPE, including helmets, safety glasses, gloves, and steel-toed boots, to protect themselves from potential hazards. 3. Secure setup: Ensure that the steel formwork is properly secured and supported to prevent collapse or movement during construction activities. 4. Regular inspection: Regularly inspect the steel formwork for any signs of wear, damage, or instability. Replace or repair any faulty components immediately. 5. Fall protection: Implement fall protection measures such as guardrails, safety harnesses, and safety nets to prevent falls from elevated platforms or edges. 6. Safe lifting: Use appropriate lifting equipment and techniques to handle heavy steel formwork components to prevent strain or injuries. 7. Communication: Establish clear communication channels between workers to ensure everyone is aware of their responsibilities and any potential safety hazards. 8. Adequate lighting: Ensure that the work area is well-lit to minimize the risk of accidents or injuries due to poor visibility. 9. Housekeeping: Maintain a clean and organized work area, removing any debris or tripping hazards to prevent accidents. 10. Emergency preparedness: Have a well-defined emergency response plan in place and make sure all workers are aware of the procedures to follow in case of an emergency.

- Q: Can steel formwork be used for both interior and exterior concrete elements?

- Steel formwork is suitable for both interior and exterior concrete elements. Its versatility makes it applicable to different construction projects. Furthermore, steel formwork is known for its durability, strength, and ability to withstand the pressure exerted by wet concrete. It also provides exceptional dimensional accuracy and ensures smooth and uniform concrete surfaces. Whether constructing interior slabs, walls, or exterior foundations, columns, or beams, steel formwork is a dependable option for both interior and exterior concrete elements.

Send your message to us

Shaft-Platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords