Shaft platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

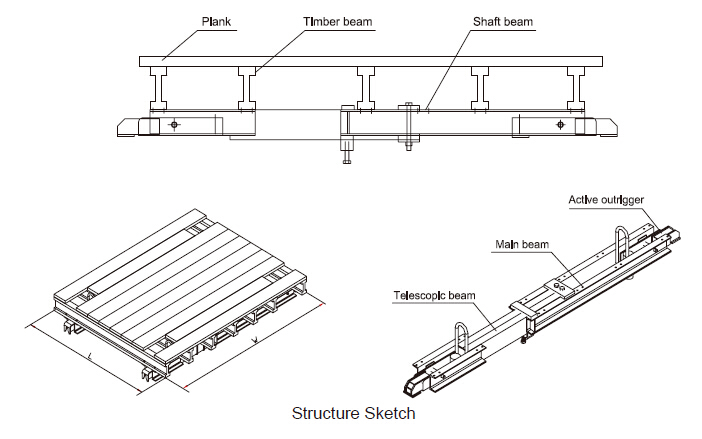

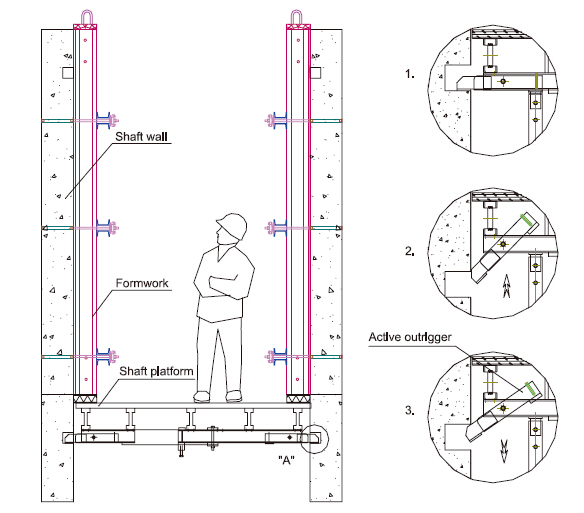

Shaft Platform

As operating platform, the shaft platform is mainly used in the concrete pouring of elevator shaft,

equipment shaft, stair shaft of high-rise building and so on.

Characteristics:

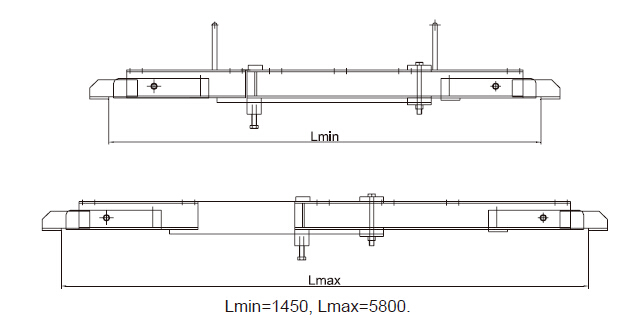

◆ The length of shaft beam is adjustable.

◆ Flexible structure makes lifting easier.

- Q: Can steel formwork be easily modified or adjusted during construction?

- Certainly, modifications or adjustments to steel formwork can be easily made during the construction process. Steel formwork is renowned for its ability to be flexible and adaptable, enabling convenient and swift modifications to meet project specifications. The design of steel formwork systems ensures modularity, enabling effortless assembly and disassembly, thereby facilitating simple modifications or adjustments to the formwork structure. Furthermore, steel formwork can be effortlessly cut, welded, or bolted together to produce custom formwork shapes or sizes. This adaptability of steel formwork makes it the preferred choice for construction projects that frequently require modifications or adjustments.

- Q: What are the different types of reinforcement used in steel formwork systems?

- Steel formwork systems utilize various types of reinforcement to enhance the structural integrity and durability of concrete structures, each serving a specific purpose. 1. Rebars, also known as steel bars, are commonly employed in steel formwork systems to provide tensile strength to the concrete. These bars are positioned in the formwork prior to pouring the concrete, effectively preventing cracking and ensuring structural stability. 2. Wire mesh reinforcement, consisting of interconnected steel wires welded or woven together, is another frequently used type in steel formwork systems. Its purpose is to evenly distribute loads across the concrete, thereby improving its strength and reducing the risk of cracking. 3. Steel fibers, discrete reinforcing elements, are often incorporated directly into the concrete mix. These fibers enhance the concrete's tensile strength, making it more resistant to cracking and enhancing overall durability. Steel fibers are especially valuable in scenarios where traditional reinforcement methods may be challenging to implement. 4. Stirrups and ties, made of steel bars, are commonly employed in reinforced concrete structures and are also integrated into steel formwork systems. They secure the main reinforcement bars in place and provide additional support to the structure. Stirrups and ties prevent rebars from shifting or bending during concrete placement, ensuring proper alignment and spacing. 5. Steel plates and brackets are utilized in formwork systems to bolster support and stability. These elements are typically affixed to the formwork panels, acting as reinforcement mechanisms that distribute loads and prevent deformation or failure. Collectively, the various types of reinforcement used in steel formwork systems play a crucial role in guaranteeing the strength, stability, and longevity of concrete structures. They work in unison to withstand external forces, prevent cracking, and enhance overall structural performance.

- Q: Can steel formwork be used for different types of concrete finishes?

- Yes, steel formwork can be used for different types of concrete finishes. Steel formwork is highly versatile and can be customized to create various concrete finishes such as smooth, textured, or patterned surfaces. The steel formwork allows for precise shaping and molding of the concrete, enabling the creation of different finishes according to the desired design and aesthetic requirements. Additionally, steel formwork can be easily adjusted and reused for different projects, making it a cost-effective choice for achieving diverse concrete finishes.

- Q: What are the common design considerations for steel formwork in seismic areas?

- When designing steel formwork for seismic areas, there are several common considerations that need to be taken into account to ensure the safety and stability of the structure. These considerations include: 1. Material strength: The steel used for formwork should have high tensile strength and ductility to withstand the seismic forces. High-strength steel, such as Grade 60 or Grade 80, is often used to ensure the formwork can resist the lateral forces generated during an earthquake. 2. Connection details: The connections between different steel formwork components need to be carefully designed to withstand seismic loads. Proper welding or bolting techniques should be employed to ensure the connections are strong enough to resist the dynamic forces. 3. Reinforcement: Additional reinforcement, such as steel bars or mesh, may be required in the formwork design to enhance its structural integrity. This reinforcement helps to distribute the seismic forces and prevent the formation of weak points or failure zones. 4. Stiffness and rigidity: The formwork system should be designed to be sufficiently stiff and rigid to minimize deformations and prevent excessive movement during an earthquake. This can be achieved by using thicker steel plates or adding diagonal bracing elements to increase the overall stiffness of the system. 5. Anchorage and support: The formwork needs to be securely anchored to the ground or the supporting structure to prevent it from shifting or collapsing during seismic events. Adequate anchorage and support systems, such as anchor bolts or braces, should be incorporated into the design to ensure the stability of the formwork. 6. Compatibility with other building components: The design of the steel formwork should consider its compatibility with other structural elements, such as concrete walls or columns. Proper coordination and integration with other building components are essential to ensure the overall stability and seismic performance of the structure. 7. Robustness and redundancy: The formwork design should have redundancy and robustness features to withstand unexpected loading conditions or localized damage during an earthquake. This can be achieved by incorporating multiple load paths or redundant structural elements into the formwork system. Overall, the common design considerations for steel formwork in seismic areas revolve around ensuring the strength, stability, and compatibility of the formwork system to withstand the dynamic forces generated by earthquakes. By addressing these considerations, engineers can develop robust and resilient formwork designs that contribute to the overall seismic safety of the structure.

- Q: What are the considerations when designing steel formwork for high-rise buildings?

- When designing steel formwork for high-rise buildings, there are several key considerations that need to be taken into account: 1. Load-bearing capacity: High-rise buildings are subjected to significant vertical and lateral loads, so the steel formwork must have the necessary load-bearing capacity to support the weight of the concrete and any additional loads such as equipment or workers. 2. Structural stability: Steel formwork must be designed to provide structural stability during the construction process. This includes considering factors such as the height of the building, wind loads, and the potential for earthquakes. Proper bracing and reinforcement are essential to ensure the formwork remains stable. 3. Durability: High-rise buildings typically require a longer construction period, and the formwork must be able to withstand the prolonged exposure to concrete, weather conditions, and repetitive use. The steel formwork should be designed with corrosion-resistant materials and protective coatings to enhance its durability. 4. Flexibility and adaptability: High-rise buildings often have complex architectural designs and irregular shapes. The formwork system should be flexible and adaptable to accommodate these variations in geometry, allowing for efficient construction and minimizing the need for custom-made components. 5. Safety: Safety is paramount in the design of steel formwork for high-rise buildings. The formwork must be designed to prevent accidents and ensure the well-being of workers. This includes incorporating safety features such as guardrails, toe boards, and safe access points. 6. Ease of assembly and disassembly: High-rise buildings require a significant amount of formwork, and the assembly and disassembly process can be time-consuming and labor-intensive. Designing the formwork system with easy-to-use connections, standardized components, and clear assembly instructions can help streamline the construction process. 7. Cost-effectiveness: High-rise construction projects often have tight budgets, and the design of the steel formwork should take into account the cost-effectiveness of the system. This includes considering factors such as the reuse potential of the formwork, minimizing the need for additional support structures, and optimizing the use of materials. By carefully considering these factors, designers can ensure the steel formwork for high-rise buildings is robust, safe, durable, and cost-effective, enabling the successful construction of these complex structures.

- Q: How does steel formwork contribute to the overall sustainability of a structure?

- There are several ways in which steel formwork contributes to the overall sustainability of a structure. To begin with, steel is a highly durable material that can withstand extreme weather conditions and resist corrosion. This means that steel formwork can be used multiple times, reducing the necessity of manufacturing new formwork for each construction project. By decreasing the demand for new materials, steel formwork helps to conserve natural resources and minimize the environmental impact associated with extracting and producing new materials. Moreover, steel formwork enables efficient and accurate construction processes. Its strength and rigidity make it capable of supporting heavy loads and providing stability during concrete pouring. This leads to quicker construction times, reducing labor costs and the use of construction equipment. The efficiency and precision provided by steel formwork contribute to the overall sustainability of a structure by conserving energy and reducing waste. Furthermore, steel formwork is a versatile and flexible choice that can be easily adjusted or modified to meet changing construction needs. This adaptability allows for the reuse of formwork in different projects, reducing the amount of waste generated. Additionally, steel formwork can be recycled at the end of its lifespan, contributing to the circular economy by decreasing landfill waste and minimizing the environmental impact associated with disposal. In conclusion, steel formwork promotes sustainability in construction by decreasing the need for new materials, conserving energy, minimizing waste, and facilitating efficient construction processes. Its durability, reusability, adaptability, and recyclability make it an environmentally friendly option that contributes to the long-term sustainability of structures.

- Q: How does steel formwork differ from other types of formwork?

- Steel formwork differs from other types of formwork in several ways. Firstly, steel formwork is highly durable and can be used multiple times, whereas other types of formwork such as wood or plywood may need to be replaced after a few uses. Additionally, steel formwork provides a smooth and precise finish, resulting in high-quality concrete structures. It also offers a higher load-bearing capacity, allowing for the construction of larger and more complex structures. Moreover, steel formwork can be easily fabricated and assembled, reducing construction time and labor costs. Overall, steel formwork is a more robust, efficient, and cost-effective solution compared to other types of formwork.

- Q: What are the different types of steel formwork ties and connectors?

- There are various types of steel formwork ties and connectors used in construction projects. Some common types include loop ties, flat ties, wedge bolts, formwork clamps, and snap ties. These ties and connectors are used to secure the formwork panels together, ensuring stability and alignment during the concrete pouring process.

- Q: Are there any specific building codes or regulations related to steel formwork?

- Yes, there are specific building codes and regulations related to steel formwork. These codes and regulations vary by country and region, but they generally cover aspects such as design, construction, installation, and safety requirements for steel formwork systems. These regulations ensure that steel formwork structures meet the necessary standards for strength, stability, and durability, while also addressing issues such as fire resistance, load capacity, and worker safety. Compliance with these codes and regulations is crucial to ensure the successful and safe use of steel formwork in construction projects.

- Q: Can steel formwork be used in architectural concrete projects?

- Yes, steel formwork can be used in architectural concrete projects. Steel formwork is a common choice for many construction projects, including architectural concrete, due to its durability, strength, and versatility. Steel formwork provides excellent support and stability to the concrete structure, ensuring that it maintains its desired shape and form during the pouring and curing process. Additionally, steel formwork is highly resistant to warping or bending under the weight and pressure of the concrete, which is crucial for achieving accurate and precise architectural designs. Steel formwork also allows for easy assembly and dismantling, making it a cost-effective option for architectural concrete projects. Overall, steel formwork is a reliable and efficient choice for architects and builders looking to create intricate and aesthetically pleasing concrete structures.

Send your message to us

Shaft platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords