Shaft-platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

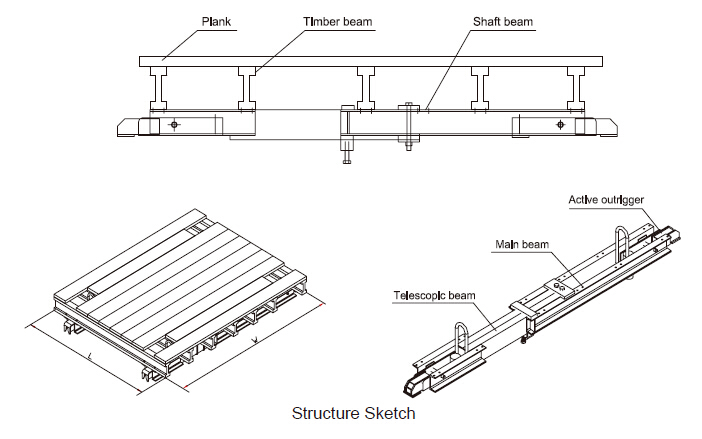

Shaft Platform

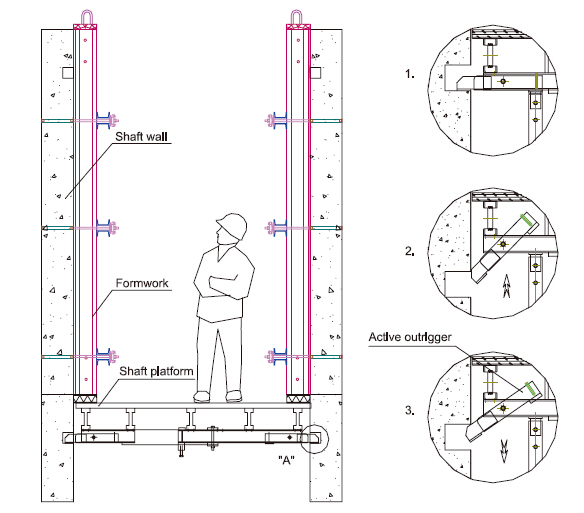

As operating platform, the shaft platform is mainly used in the concrete pouring of elevator shaft,

equipment shaft, stair shaft of high-rise building and so on.

Characteristics:

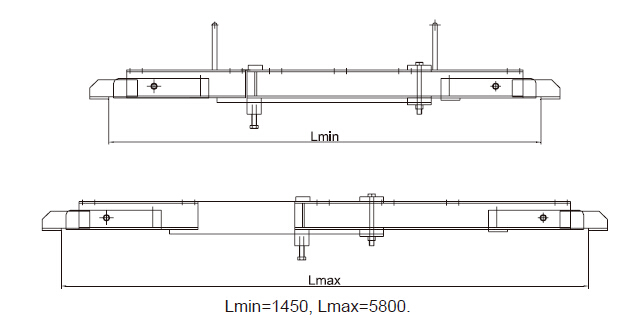

◆ The length of shaft beam is adjustable.

◆ Flexible structure makes lifting easier.

- Q: How does steel formwork handle formwork repositioning?

- Steel formwork is renowned for its strength and durability, making it an ideal option for projects that necessitate frequent formwork repositioning. In terms of managing formwork repositioning, steel formwork offers numerous advantages. To begin with, steel formwork is engineered to be easily dismantled and reassembled, rendering it highly adaptable to changing project requirements. Consequently, the formwork can be swiftly and efficiently relocated to accommodate alterations in design or construction plans. Steel formwork systems often consist of interchangeable modular components, enabling seamless formwork repositioning without compromising structural integrity. Moreover, steel formwork is recognized for its impressive load-bearing capacity. This renders it suitable for supporting substantial concrete loads during the construction process. When formwork necessitates repositioning, steel formwork systems can withstand the stresses and strains associated with lifting and moving, guaranteeing the formwork's stability and security throughout the repositioning process. This substantial load-bearing capacity also permits the usage of larger formwork panels, reducing the number of components that require repositioning and thus saving time and labor. Additionally, steel formwork provides excellent dimensional stability. Consequently, once the formwork is repositioned, it retains its original shape and dimensions, ensuring accurate and consistent concrete placement. This is particularly crucial for projects that require precise alignment and uniformity in the finished structure. Furthermore, steel formwork exhibits high resistance to warping, bending, and deformation, even when subjected to multiple repositioning cycles. This guarantees that the formwork remains in optimal condition, minimizing the need for repairs or replacements and reducing downtime on the construction site. In conclusion, steel formwork is exceptionally well-suited to handling formwork repositioning due to its adaptability, high load-bearing capacity, dimensional stability, and resistance to warping. These characteristics make it a dependable and efficient choice for construction projects that necessitate frequent formwork adjustments.

- Q: How does steel formwork contribute to the overall efficiency of concrete placement?

- The overall efficiency of concrete placement is greatly enhanced by steel formwork. Firstly, the durability of steel formwork allows it to withstand the pressure exerted by fresh concrete, ensuring that it remains intact throughout the pouring and curing process. This minimizes the need for repairs or replacements and allows the construction process to proceed smoothly without delays. In addition to its durability, steel formwork is also known for its high strength and stability. This enables the construction of larger and taller concrete structures, as the formwork can support the weight and pressure without buckling or deforming. Contractors can take advantage of this strength and stability to construct complex shapes and designs, meeting specific architectural requirements efficiently. Steel formwork also offers easy and precise assembly due to its modular nature. This allows for quick installation and dismantling, significantly reducing construction time. The standardized components ensure accurate alignment, leading to consistent and uniform concrete placement. This not only enhances efficiency but also contributes to the quality and aesthetics of the final concrete structure. Furthermore, steel formwork is reusable, unlike traditional timber formwork. This reduces material waste and saves costs as the formwork can be utilized multiple times. The ability to reuse the formwork eliminates the constant need for procurement and disposal of materials, streamlining the construction process and improving overall efficiency. Lastly, steel formwork provides a smooth finish to the concrete surface. Its rigid structure prevents any bulges or deformities, resulting in a flat and even surface. This eliminates the need for additional surface treatments, saving time and resources. The smooth finish not only enhances the aesthetic appeal but also improves the durability and longevity of the concrete structure. In conclusion, steel formwork plays a crucial role in enhancing the efficiency of concrete placement. Its durability, strength, easy assembly, reusability, and ability to provide a smooth finish make it an invaluable tool in the construction industry. Contractors can expedite the construction process, reduce material waste, and achieve high-quality concrete structures efficiently by utilizing steel formwork.

- Q: What are the different surface finishes available for steel formwork?

- There are several different surface finishes available for steel formwork, depending on the specific requirements and preferences of the project. 1. Smooth finish: This is the most common surface finish for steel formwork. It involves grinding or sanding the surface to create a smooth and even appearance. Smooth finishes are ideal for projects that require a high level of precision and aesthetic appeal. 2. Textured finish: Some projects may require a textured surface finish for better bonding with concrete. This can be achieved through various methods, such as shot blasting or using textured form liners. Textured finishes provide additional grip and can enhance the bond between the formwork and concrete. 3. Brushed finish: Brushed finishes involve using wire brushes or abrasive pads to create a slightly rougher surface. This finish is often chosen for applications where slip resistance is important, such as on ramps or walkways. 4. Etched finish: Etching is a chemical process that creates a matte or patterned finish on steel formwork. This finish is commonly used for decorative purposes, as it can create unique designs or patterns on the surface. 5. Galvanized finish: Galvanizing is a coating process that involves applying a layer of zinc to the steel formwork. This finish provides excellent corrosion resistance, making it suitable for projects in harsh or corrosive environments, such as marine or industrial applications. 6. Powder-coated finish: Powder coating is a durable and decorative finish that involves applying a dry powder to the steel formwork and then curing it with heat. This finish is available in a wide range of colors and provides excellent resistance to impact, chemicals, and UV radiation. It's important to consider the specific requirements of the project, such as durability, aesthetics, and environmental conditions, when selecting the appropriate surface finish for steel formwork. Consulting with a structural engineer or formwork supplier can help determine the best finish for the intended application.

- Q: Is steel formwork suitable for projects with high concrete pressure?

- Yes, steel formwork is suitable for projects with high concrete pressure. Steel formwork is known for its high strength and durability, making it capable of withstanding the pressure exerted by high volumes of concrete. It provides excellent support and stability to the concrete during the pouring and curing process, ensuring a successful and safe construction project.

- Q: What are the considerations when designing steel formwork for elevated slabs?

- When designing steel formwork for elevated slabs, there are several considerations that need to be taken into account. These considerations include the overall structural requirements, the loadings and stresses that the formwork will be subjected to, the ease of installation and removal, the material properties and durability, and the safety of workers during the construction process. One of the primary considerations is the structural requirements of the formwork. The formwork needs to be designed to support the weight of the wet concrete, as well as any additional loads that may be imposed during the construction process. This includes considering the design loads, such as dead loads, live loads, and impact loads, and ensuring that the formwork can safely carry these loads without excessive deflection or failure. Another important consideration is the ease of installation and removal. Steel formwork should be designed to be easily assembled and disassembled, allowing for efficient construction processes. This includes considering the size and weight of the individual formwork components, as well as the connections between them. Additionally, the design should allow for easy access to the formwork for workers to pour and finish the concrete. The material properties and durability of the steel formwork are also important considerations. The formwork needs to be made from high-quality steel that is capable of withstanding the stresses and loads imposed during the construction process. The steel should have sufficient strength, ductility, and resistance to corrosion to ensure the long-term durability of the formwork. Safety is another critical consideration when designing steel formwork for elevated slabs. The design should incorporate appropriate safety features, such as handrails, guardrails, and non-slip surfaces, to protect workers from falls and other hazards. Additionally, the formwork should be designed to minimize the risk of accidents during installation and removal, such as by providing secure connections and clear instructions for assembly and disassembly. In summary, when designing steel formwork for elevated slabs, it is important to consider the structural requirements, loadings and stresses, ease of installation and removal, material properties and durability, and the safety of workers. By carefully considering these factors, designers can ensure the successful construction of elevated slabs using steel formwork.

- Q: How does steel formwork contribute to the overall energy efficiency of the building?

- Steel formwork contributes to the overall energy efficiency of a building in several ways. Firstly, steel has excellent thermal conductivity, allowing it to absorb and dissipate heat effectively, which helps in maintaining a comfortable indoor temperature and reducing the reliance on heating and cooling systems. Additionally, steel formwork provides a strong and durable structure that minimizes air leakage and heat loss, improving the overall insulation of the building. Moreover, steel formwork is reusable and can be easily dismantled and repurposed, reducing the energy and resources required for manufacturing new formwork for future construction projects. Overall, steel formwork plays a crucial role in enhancing the energy efficiency of buildings, leading to reduced energy consumption and lower carbon emissions.

- Q: How does steel formwork affect the overall construction site organization?

- Steel formwork can have a significant impact on the overall organization of a construction site. Firstly, steel formwork is known for its durability and reusability, which means it can be used multiple times for different projects. This allows for better planning and scheduling of construction activities, as the availability of formwork is more predictable and reliable. Additionally, steel formwork is known for its precision and accuracy, which leads to better quality construction. This can result in fewer reworks and delays, as the formwork ensures that concrete is poured in the right place and to the correct dimensions. Consequently, the overall construction process becomes more efficient, allowing for better organization and coordination of various trades and activities on the site. Steel formwork also offers flexibility in design and construction. It can be easily adjusted and modified to accommodate changes in the project, such as alterations in the shape or size of concrete elements. This adaptability reduces the need for additional materials and resources, which can streamline the organization of the construction site and minimize waste. Furthermore, steel formwork is known for its strength and stability. This allows for taller and larger concrete structures to be constructed, which can have implications for the overall layout and organization of the site. For example, it may require additional crane or lifting equipment to handle the heavier and larger formwork components. This necessitates careful planning and coordination to ensure that the site is properly organized to accommodate these requirements. In summary, steel formwork positively impacts the overall organization of a construction site by providing durability, precision, flexibility, and strength. These attributes contribute to better planning, scheduling, and coordination of construction activities, resulting in improved efficiency, quality, and adaptability.

- Q: Are there any maintenance requirements for steel formwork?

- Maintenance requirements exist for steel formwork. Although steel formwork is durable and long-lasting, regular maintenance is necessary to ensure proper functioning and extend its lifespan. Cleaning is one of the primary maintenance requirements for steel formwork. After each use, it is important to thoroughly clean the formwork to remove concrete residue, dirt, and debris. This can be achieved by using water and a mild detergent or specialized cleaning agents for steel surfaces. Regular cleaning prevents the accumulation of corrosive substances that can harm the formwork over time. Inspecting the steel formwork for any signs of damage or wear is also crucial. This should be done both before and after each use to identify cracks, dents, or deformities that may compromise its structural integrity. If any damages are found, prompt repairs are necessary to prevent further deterioration. Proper storage and handling of steel formwork are essential maintenance practices. After use, the formwork should be stored in a dry and well-ventilated area to prevent moisture buildup, which can cause rust and corrosion. Additionally, it should be handled with care during transportation and installation to avoid accidental damage. Applying a protective coating or paint to the steel formwork can enhance its durability and resistance to corrosion. This coating should be applied according to the manufacturer's instructions and periodically checked for any signs of deterioration. If the coating shows wear, it should be reapplied to maintain the formwork's protective properties. Regular maintenance of steel formwork not only ensures its longevity but also enhances safety on construction sites. By promptly addressing potential issues, construction projects can proceed smoothly, minimizing the risk of accidents or delays. Therefore, following recommended maintenance practices is essential to maximize the performance and lifespan of steel formwork.

- Q: Are there any specific considerations for using steel formwork in areas with high traffic loads?

- There are various factors to take into account when using steel formwork in areas with high traffic loads. Firstly, it is crucial to carefully assess the strength and durability of the steel formwork to ensure it can withstand the heavy loads and constant traffic. Steel formwork is renowned for its robustness and load-bearing capacity, making it suitable for such applications. However, it is important to select the appropriate type and grade of steel that can endure the specific traffic loads in the area. Secondly, it is imperative to entrust the design and construction of the formwork system to experienced professionals who understand the requirements of high traffic loads. Adequate reinforcement and bracing should be incorporated to enhance the strength and stability of the formwork structure. This may involve utilizing additional steel supports or beams to distribute the loads more effectively. Moreover, the connections and joints between different formwork elements should be meticulously designed and constructed to ensure they can withstand the heavy traffic loads without any failures. Welding or bolting techniques may be employed to enhance the structural integrity of the formwork system. Additionally, regular inspection and maintenance of the steel formwork should be conducted to identify any indications of wear and tear or damage caused by the high traffic loads. Any damaged or weakened sections should be promptly repaired or reinforced to avoid any safety hazards. Lastly, it is crucial to consider the impact of the high traffic loads on the poured concrete. The concrete mix and pouring techniques should be carefully chosen to ensure they can withstand the dynamic loads caused by heavy traffic. Reinforcement measures such as using steel rebar or fiber reinforcement can also be considered to augment the strength and durability of the concrete. In conclusion, when employing steel formwork in areas with high traffic loads, it is essential to consider the strength and durability of the formwork, design and construction techniques, connections and joints, regular inspection and maintenance, as well as the impact on the concrete. By taking these specific considerations into account, the steel formwork can provide a secure and dependable solution for construction projects in high traffic areas.

- Q: How does steel formwork contribute to easier formwork removal?

- Steel formwork contributes to easier formwork removal in several ways. Firstly, steel formwork is known for its high strength and durability. This means that it can withstand the pressure and weight of the concrete without deforming or warping. As a result, there is minimal damage or deformation to the formwork after the concrete is poured and cured. Secondly, steel formwork is designed with smooth surfaces, which allows for easy release of the formwork from the cured concrete. The smooth surface prevents the concrete from sticking to the formwork, making it easier to remove. This is particularly beneficial when working with complex shapes and intricate designs, as the formwork can be easily removed without causing any damage to the concrete. Additionally, steel formwork is often constructed with detachable parts or panels. This allows for easy assembly and disassembly of the formwork, making it quicker and more efficient to remove. The detachable parts also make it easier to clean and maintain the formwork, ensuring its longevity and reusability. Furthermore, steel formwork is highly resistant to moisture and chemicals, which are often present in the concrete or construction environment. This resistance prevents the formwork from deteriorating or becoming weakened over time. As a result, the formwork remains intact and in good condition, making it easier to remove after the concrete has set. Overall, the strength, durability, smooth surfaces, detachable parts, and resistance to moisture and chemicals make steel formwork an ideal choice for easier formwork removal. It not only simplifies the process but also ensures the quality and integrity of the concrete structure being built.

Send your message to us

Shaft-platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords