Shaft Platform for Formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

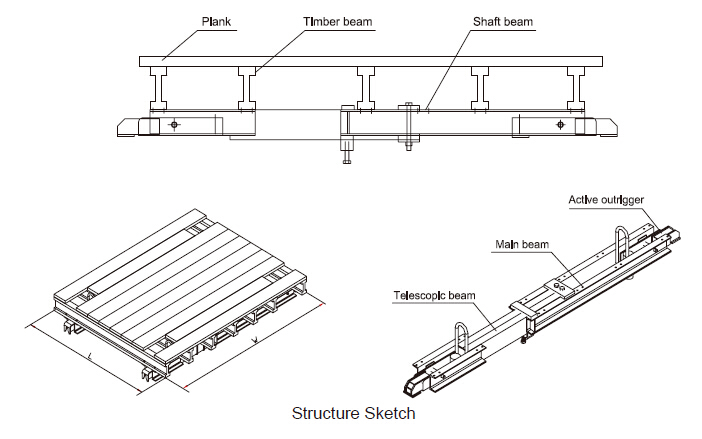

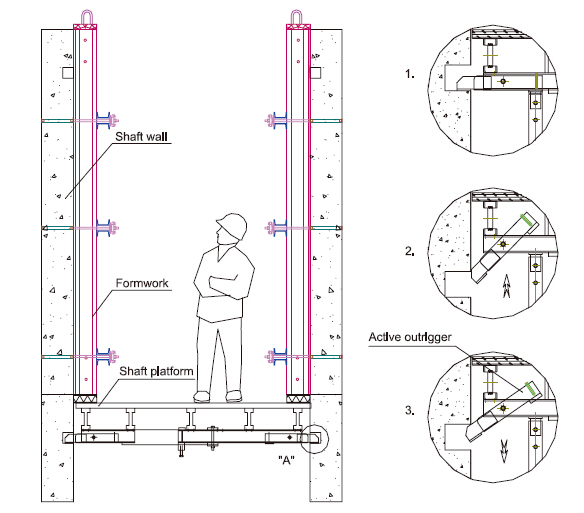

Shaft Platform

As operating platform, the shaft platform is mainly used in the concrete pouring of elevator shaft,

equipment shaft, stair shaft of high-rise building and so on.

Characteristics:

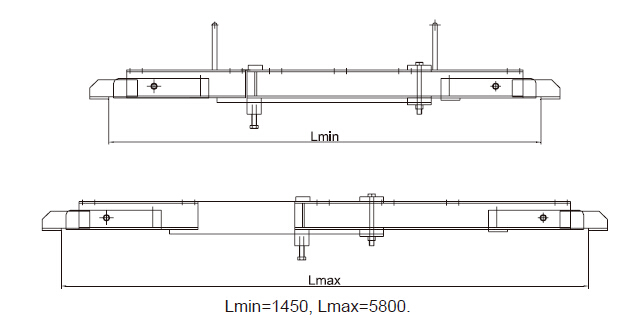

◆ The length of shaft beam is adjustable.

◆ Flexible structure makes lifting easier.

- Q: How does steel formwork affect the overall energy efficiency of a structure?

- Steel formwork can significantly improve the overall energy efficiency of a structure. It provides a durable and reusable framework for concrete pouring, reducing material waste and construction time. The precise fit of steel formwork minimizes the need for additional insulation, resulting in better thermal performance and reduced energy consumption for heating and cooling. Additionally, its strength and stability allow for the construction of thinner walls and slabs, maximizing the usable space and minimizing the amount of materials required. Thus, steel formwork positively impacts the energy efficiency of a structure by reducing energy consumption and promoting sustainable construction practices.

- Q: What are the common challenges faced when using steel formwork?

- Some common challenges faced when using steel formwork include its high initial cost compared to other formwork materials, its heavy weight which can make handling and transportation difficult, the need for skilled labor to install and dismantle it properly, the possibility of rust and corrosion if not properly maintained, and the limited flexibility in terms of shape and size compared to other formwork systems.

- Q: What are the considerations when designing steel formwork for stairs?

- Several important considerations must be kept in mind when designing steel formwork for stairs. Firstly, it is crucial to carefully calculate and design the structural integrity and load-bearing capacity of the formwork. Stairs experience significant dynamic loads from people walking up and down, so the formwork must be able to support these loads without any deformation or failure. Accurately determining the dimensions and shape of the stairs is also essential to ensure a proper fit within the formwork. This involves considering the rise, tread, and overall dimensions of each step, as well as any landings or platforms that may be present. The formwork needs to be designed to accommodate these dimensions while providing a smooth and safe construction surface. The construction process and ease of installation should be taken into account as well. The steel formwork for stairs should be designed to be easily assembled, disassembled, and transported to the construction site. It should also allow for easy access during the construction process, ensuring that workers can safely and efficiently complete their tasks. Durability and longevity are crucial factors when designing steel formwork for stairs. While steel is a strong and durable material, it is important to consider the potential for corrosion and wear over time. The design should incorporate proper coatings and protective measures to prevent corrosion and ensure the formwork's longevity. Finally, safety is of utmost importance when designing steel formwork for stairs. The formwork should be designed to provide a secure and stable working platform for construction workers. This may involve incorporating handrails, non-slip surfaces, and other safety features to minimize the risk of accidents or falls during construction. In conclusion, when designing steel formwork for stairs, it is important to consider factors such as structural integrity, dimensions, ease of installation, durability, and safety. By carefully considering these factors, a well-designed steel formwork system can be created to efficiently and effectively construct stairs in a safe and reliable manner.

- Q: How does steel formwork contribute to the overall stability of a structure?

- Steel formwork contributes to the overall stability of a structure by providing a robust and rigid framework for concrete placement. Its strength and durability prevent deformation or displacement during the pouring and curing process, ensuring the concrete sets in the desired shape and position. This stability allows for the proper alignment and distribution of loads, enhancing the structural integrity of the building and reducing the risk of any potential structural failures.

- Q: How does steel formwork affect the overall construction cost estimate?

- Steel formwork can have a significant impact on the overall construction cost estimate. While steel formwork may have a higher initial cost compared to other types of formwork, it offers several advantages that can offset this expense. Steel formwork is durable, reusable, and can be easily assembled and disassembled, resulting in reduced labor costs and increased efficiency. Additionally, steel formwork provides a smooth surface finish, which can minimize the need for additional surface treatments, saving both time and money. Overall, although steel formwork may require a higher upfront investment, its long-term benefits can lead to cost savings in the construction process.

- Q: What are the common cost-saving strategies when using steel formwork?

- Some common cost-saving strategies when using steel formwork include reusing the formwork for multiple projects, accurately measuring and cutting the formwork materials to minimize waste, properly maintaining and storing the formwork to prolong its lifespan, and utilizing innovative formwork systems that allow for faster installation and dismantling.

- Q: How does steel formwork contribute to the overall acoustics of the structure?

- Steel formwork does not directly contribute to the overall acoustics of a structure as its primary function is to provide support and shape during the construction process. The acoustics of a building are primarily influenced by the design and materials used for the walls, ceilings, and floors, which are usually installed after the steel formwork is removed.

- Q: Position of horizontal construction joint of shear wall. The first layer is higher than the standard layer, the large template in accordance with the standard layer, the first part of the difference with the roof can be poured?

- Large template in accordance with the standard layer, the difference between the first part of the roof can be poured?

- Q: Are there any specific considerations for using steel formwork in areas with limited power supply?

- Yes, there are several specific considerations for using steel formwork in areas with limited power supply. Firstly, since steel formwork requires power tools for installation and removal, alternative methods such as manual labor or non-powered equipment may need to be employed. Additionally, the limited power supply may affect the availability of electricity for welding, which is often required for steel formwork assembly. Therefore, alternative joining methods such as bolting or mechanical fastening may need to be explored. Finally, the transportation and storage of steel formwork components in areas with limited power supply may require additional planning to ensure their accessibility and protection.

- Q: What are the different types of connections used in steel formwork?

- There are several different types of connections commonly used in steel formwork, each with its own advantages and applications. Some of the most common types include: 1. Bolted connections: These connections involve using bolts and nuts to secure the formwork components together. Bolted connections are versatile, relatively easy to assemble and disassemble, and provide a high level of strength and stability. They are often used for larger formwork structures or where high loads are expected. 2. Welded connections: Welding is another popular method of connecting steel formwork components. Welded connections offer excellent strength and durability, as the pieces are fused together. However, welding requires skilled labor and specialized equipment, which can increase costs and time. 3. Clamped connections: Clamped connections involve using clamps or couplers to hold the formwork components together. Clamped connections are quick to assemble and disassemble, making them ideal for temporary structures or situations where frequent changes are required. They also offer flexibility in terms of adjusting the formwork components' position. 4. Pin connections: Pin connections involve using pins or dowels to join the formwork components together. These connections are relatively simple and can be quickly assembled or disassembled. However, pin connections may not offer the same level of strength as bolted or welded connections. 5. Adhesive connections: Adhesive connections involve using an adhesive or epoxy to bond the formwork components together. This type of connection is commonly used for smaller or lightweight formwork structures. Adhesive connections provide a strong bond and are often used in situations where welding or bolting is not feasible. Each type of connection has its own advantages and disadvantages, and the choice depends on factors such as the formwork structure's size, load requirements, desired level of strength, and project timeline. Consulting with a structural engineer or formwork specialist can help determine the most suitable connection type for a specific project.

Send your message to us

Shaft Platform for Formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords