Shaft Platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

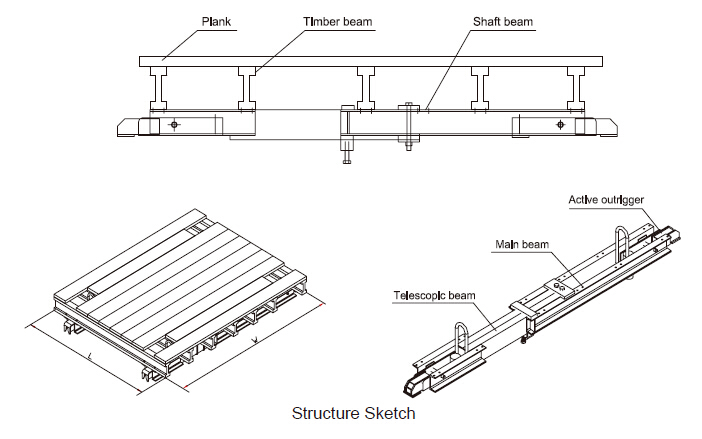

Shaft Platform

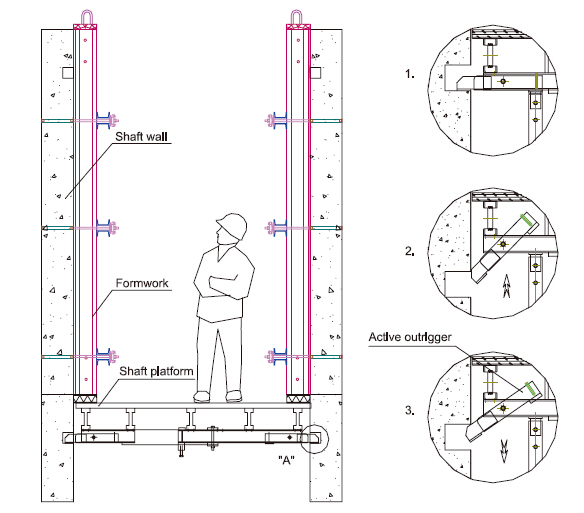

As operating platform, the shaft platform is mainly used in the concrete pouring of elevator shaft,

equipment shaft, stair shaft of high-rise building and so on.

Characteristics:

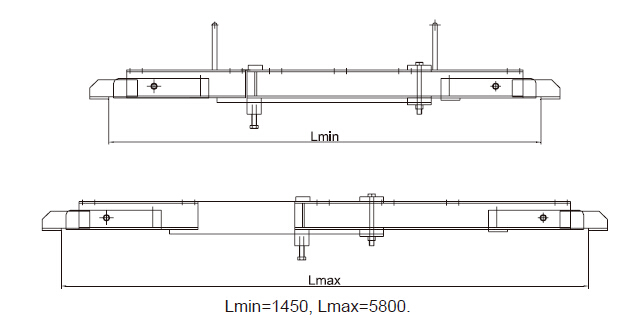

◆ The length of shaft beam is adjustable.

◆ Flexible structure makes lifting easier.

- Q: How does steel formwork handle formwork stripping and cleaning?

- The durability and strength of steel formwork make it highly suitable for formwork stripping and cleaning processes. When it comes to removing the formwork, steel formwork can be easily disassembled and taken off the concrete structure without causing any damage. This is possible because steel is inherently rigid and stable, allowing for efficient and safe stripping. In addition, steel formwork is resistant to moisture, chemicals, and other environmental factors, which makes it easier to clean and maintain. Once the formwork is stripped, any concrete residue or debris can be easily cleaned off the steel surface using appropriate cleaning techniques. This may involve using high-pressure water jets, scrubbing, or other cleaning agents, depending on the specific requirements. Furthermore, steel formwork can be reused multiple times without significant deterioration. After cleaning, the formwork can be inspected for any damages or wear and tear. Any necessary repairs or replacements can be made to ensure the integrity of the formwork for future use. Overall, steel formwork is an efficient choice for handling formwork stripping and cleaning due to its durability, strength, and resistance to environmental factors. Its easy disassembly, cleaning capabilities, and reusability make it a preferred option for construction projects where regular formwork stripping and maintenance is required.

- Q: Can steel formwork be easily modified or adjusted during construction?

- Certainly, modifications or adjustments to steel formwork can be easily made during the construction process. Steel formwork is renowned for its ability to be flexible and adaptable, enabling convenient and swift modifications to meet project specifications. The design of steel formwork systems ensures modularity, enabling effortless assembly and disassembly, thereby facilitating simple modifications or adjustments to the formwork structure. Furthermore, steel formwork can be effortlessly cut, welded, or bolted together to produce custom formwork shapes or sizes. This adaptability of steel formwork makes it the preferred choice for construction projects that frequently require modifications or adjustments.

- Q: How does steel formwork affect the overall acoustics of the building?

- The overall acoustics of a building can be greatly influenced by the use of steel formwork. Steel formwork, due to its dense and rigid nature, tends to reflect sound waves rather than absorb them. This reflection can result in increased noise levels and the creation of echoes within the building. The utilization of steel formwork can lead to a longer reverberation time, which is the duration it takes for sound to diminish by 60 decibels. This can result in poor speech clarity and reduced audio quality within the space. Moreover, the sound reflections from steel formwork can disrupt the natural acoustic properties of the room, potentially causing distortion and resonance problems. To tackle these challenges, it is possible to incorporate sound-absorbing materials on the interior surfaces of the building. This can help decrease the reflection and reverberation of sound waves, thereby enhancing the overall acoustics of the space. Possible options include the use of acoustic panels, insulation materials, and ceiling treatments that absorb and scatter sound. When determining the type of formwork to be used, it is crucial to consider the specific requirements of the building and its intended purpose. For spaces where excellent acoustics are essential, such as auditoriums, concert halls, or recording studios, alternative formwork materials that offer superior sound absorption properties might be preferred over steel formwork. However, in other applications where acoustics are less critical, steel formwork can still be utilized effectively by incorporating appropriate sound-absorbing measures. In conclusion, the selection of steel formwork can significantly impact the acoustics of a building. By carefully considering sound absorption and reflection properties, and by implementing additional acoustic treatments, it is possible to mitigate any negative effects and create a more pleasant and functional acoustic environment.

- Q: How does steel formwork affect the overall material wastage in construction?

- Steel formwork can greatly reduce material wastage in construction projects. Unlike traditional timber formwork, which is often single-use and needs to be discarded after each use, steel formwork is reusable and can be used multiple times. This significantly reduces the need for new materials, such as timber, plywood, or plastic, which would otherwise contribute to material wastage. Additionally, steel formwork is highly durable and can withstand harsh weather conditions, impacts, and vibrations. This durability ensures that the formwork remains intact and functional for a longer period, reducing the need for frequent replacements and further minimizing material wastage. Moreover, steel formwork is highly customizable and can be easily adjusted and modified to fit different project requirements. This flexibility allows for precise shaping and molding of concrete structures, resulting in reduced material wastage. With timber formwork, achieving complex shapes or curves can be challenging and may lead to excessive cutting and wastage. Furthermore, steel formwork offers excellent dimensional stability, ensuring accurate and consistent concrete placement. This eliminates the need for rework, which can result in material wastage. Additionally, steel formwork provides a smooth surface finish, reducing the requirement for additional finishing materials, such as plaster, which again minimizes material wastage. Overall, the use of steel formwork in construction projects can significantly reduce material wastage. Its reusability, durability, flexibility, dimensional stability, and smooth surface finish contribute to optimizing material usage, minimizing the need for new materials, and ultimately reducing overall material wastage.

- Q: What is the maximum load that steel formwork can bear?

- The maximum load that steel formwork can bear depends on various factors such as the type and thickness of the steel used, the design and construction of the formwork, and the support system in place. Steel formwork is known for its strength and durability, making it capable of supporting heavy loads. However, it is important to consult the manufacturer's specifications and guidelines to determine the exact maximum load capacity of a particular steel formwork system. These specifications are typically based on extensive testing and engineering calculations, ensuring the safety and structural integrity of the formwork. Additionally, it is crucial to consider other factors such as the load distribution, formwork layout, and the overall stability of the structure. Professional engineers and contractors should be involved in the design and installation process to ensure that the maximum load capacity is not exceeded and that the formwork is safely supported throughout the construction process.

- Q: What are the different safety precautions to be followed during steel formwork installation?

- To ensure the safety of workers and the successful completion of the project, there are several safety precautions that must be adhered to during the installation of steel formwork. These precautions encompass: 1. Adequate training and supervision: All workers involved in the installation process must undergo proper training in the handling of steel formwork and its components. Additionally, they should receive sufficient supervision to ensure compliance with safety guidelines. 2. Utilization of personal protective equipment (PPE): Workers must be provided with and mandated to wear the appropriate PPE, including hard hats, safety goggles, gloves, and steel-toed boots. This will safeguard them against potential hazards such as falling objects or sharp edges. 3. Assurance of secure footing: It is imperative to establish a stable and secure footing for workers during formwork installation. This can be accomplished by clearing debris, maintaining a clean and organized work area, and furnishing stable platforms or scaffolding. 4. Implementation of fall protection measures: Particularly when working at heights, it is necessary to implement fall protection measures. These may involve the installation of guardrails, safety nets, or personal fall arrest systems. Workers should also receive training on the proper utilization of these systems and equipment. 5. Adoption of appropriate lifting techniques: The utilization of heavy steel formwork components necessitates the adoption of proper lifting techniques to prevent strains, sprains, or other injuries. Workers should be trained on correct lifting methods, such as bending at the knees and utilizing leg muscles rather than the back. 6. Conducting equipment inspections: Regular inspections of all equipment, including cranes, hoists, and lifting devices, must be conducted to ensure they are in proper working order. Any defective equipment should be promptly repaired or replaced. 7. Promotion of communication and coordination: Effective communication and coordination among workers are vital to maintaining a safe working environment. This entails clear instructions, proper signage, and regular safety meetings to address concerns or potential hazards. 8. Adherence to fire safety protocols: The installation of steel formwork may involve the use of welding or cutting equipment, which poses a fire hazard. Adequate fire prevention measures, such as fire extinguishers and fire-resistant barriers, should be in place, and workers should be trained on proper fire safety procedures. 9. Establishment of emergency response plans: Well-defined emergency response plans, including evacuation procedures, first aid protocols, and means of contacting emergency services, must be established. All workers should be familiar with these plans and understand their roles and responsibilities in the event of an emergency. By diligently following these safety precautions, the risks associated with steel formwork installation can be minimized, ensuring the safety and well-being of workers and the successful completion of the project.

- Q: Can steel formwork be used for structures with high load-bearing requirements?

- Yes, steel formwork can be used for structures with high load-bearing requirements. Steel is known for its high strength and durability, making it a suitable choice for heavy-duty applications. Steel formwork provides excellent support during the construction process, allowing for the creation of structures that can withstand significant loads. Additionally, steel formwork offers superior dimensional stability, ensuring that the structure maintains its shape and can bear the required loads over time. Combined with proper reinforcement and design, steel formwork can effectively handle high load-bearing requirements in various construction projects.

- Q: How does steel formwork accommodate for different concrete pouring rates?

- Steel formwork can accommodate different concrete pouring rates by its ability to withstand high pressures exerted by the concrete. The strength and rigidity of steel allow it to contain and support the concrete, regardless of the speed at which it is poured. This ensures that the formwork remains stable and intact, preventing any deformations or collapses during the pouring process.

- Q: Can steel formwork be used for both horizontal and vertical structures?

- Steel formwork is capable of being utilized for both horizontal and vertical structures. This adaptable construction material can be effortlessly modified and recycled, rendering it appropriate for diverse kinds of structures. It offers exceptional robustness and stability, rendering it perfect for supporting substantial concrete loads in both horizontal and vertical implementations. Customizable and configurable, steel formwork systems can be assembled to meet the distinct needs of distinct construction ventures, facilitating efficient and precise construction of horizontal slabs and vertical walls. Its durability and resistance to deterioration establish it as a dependable option for long-lasting utilization in an array of construction applications.

- Q: Can steel formwork be used for structures with high fire resistance requirements?

- Structures with stringent fire safety standards can indeed utilize steel formwork. Steel possesses excellent fire resistance properties due to its high melting point, enabling it to endure high temperatures for longer durations than other materials. Consequently, steel is an optimal choice for such structures. To ensure compliance with fire resistance requirements, careful consideration must be given to the design and construction techniques when employing steel formwork. Proper insulation of the steel formwork is crucial to prevent heat transfer to the concrete structure during a fire. This can be accomplished by utilizing fire-resistant insulation materials or applying a fire-resistant coating to the steel formwork. Moreover, it is essential to evaluate the fire resistance of the concrete itself. Concrete inherently exhibits fire-resistant characteristics due to its high density and low thermal conductivity. However, the inclusion of specific additives, such as fire-resistant admixtures or fibers, can further enhance its fire resistance. By combining the fire-resistant attributes of steel formwork with appropriate design and construction techniques, structures that satisfy elevated fire resistance requirements can be achieved. Nonetheless, it is highly recommended to consult fire safety experts and adhere to local building codes and regulations to ensure the utmost level of fire safety in all construction projects.

Send your message to us

Shaft Platform for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords