Sewing Fiberglass Fabric FRP Pultrusion Roof Tile Sheets or Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500M2 m²

- Supply Capability:

- 900M2/Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Pultrusion Roof Tile Sheets or Panels

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility.

Today, we’re planning to win more market shares in the world and let more customers know us.

Photos

Product Traits

1. Corrosion resistance no rust, no maintenance, long service life.

2. Lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%). In this situation, the density of glass fiber reinforced plastic is only about a quarter of the steel.

3. The intensity and stiffness is quite prominent,.

4. Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

5. Anti-aging select highquality FRP pultrusion profiles, the service life of the product can be more than 20 years.

6. Anti-UV agent are added into all pultrusion FRP profiles get the best anti-uv effect.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

Easy to maintain.

High strength.

Long service life.

Easy to install.

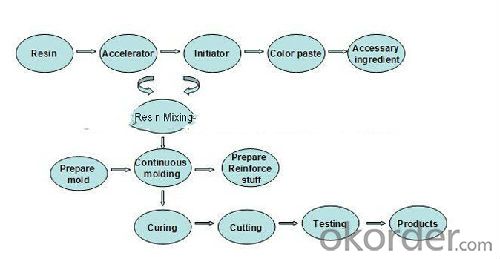

Production Process

Specification

Mechanical properties: high rigidity lighting panels

Plate matches: match with general prepainted galvanized sheet, galvanized steel

Resin composites: Improved anti-aging SMR198 resin

Fiber reinforcement: E-glass fiber untwisted without glue

Surface treatment: affixing MELINEX301 film

Stiffener line: surface with longitudinal uniform distribution of anti-LAC gluten

Glass fiber: not less than 28%

Unit Weight: 1800g / ㎡, 2400g / ㎡, 3050g / ㎡

Nominal thickness: 1.2 mm, 1.5mm, 2.0mm (tolerance ≤ 10%)

Temperature limits: -60 ℃ ~ +130 ℃

Transmittance (1.5mm): 72% ± 2% (fog white, sky blue, water green), 52% ± 2% (white porcelain)

UV-rate: 99%

Tensile strength: 90Mpa

Flexural strength: 160 Mpa

Elongation: 1.9%

Pap hardness: ≥ 50

Thermal expansion coefficient: 1.5 ~ 3.2 * 10-5 / K

Thermal conductivity: K = 0.23W / m * K

Guarantee: 15 years

NOTE: In special cases, the surface film varieties vary according to needs, such as Melinex389, PT055 and so on

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Can fiberglass fabric be used for making tarpaulins?

- Yes, fiberglass fabric can be used for making tarpaulins. Fiberglass is known for its high strength and durability, making it an excellent choice for creating tarpaulins that can withstand harsh weather conditions and provide effective protection. Additionally, fiberglass fabric is resistant to tearing, UV rays, and chemicals, making it a reliable material for tarpaulin manufacturing.

- Q: Do fiberglass fabrics have any electrical conductivity properties?

- Fiberglass fabrics lack electrical conductivity, meaning they do not possess any properties that allow them to conduct electricity. As an insulator, fiberglass is incapable of conducting electrical current. This characteristic renders it suitable for a wide range of applications that demand electrical insulation, including electrical insulation sleeves, circuit boards, and protective covers for electrical equipment. Moreover, fiberglass fabrics find common usage in industries where insulation from heat and fire is indispensable, further emphasizing their non-conductivity to electricity.

- Q: Can fiberglass fabric be laminated with other materials?

- Yes, fiberglass fabric can be laminated with other materials. Laminating refers to the process of bonding two or more layers of material together to create a composite material with enhanced properties. Fiberglass fabric is often used as a reinforcement material in laminates, providing strength and durability. It can be laminated with various materials such as resins, plastics, metals, and other fabrics to create composite structures with specific characteristics. The lamination process typically involves applying a layer of adhesive or resin onto the fiberglass fabric and then bonding it with the desired material. This allows for the creation of versatile and customizable materials that can be used in a wide range of applications such as aerospace, automotive, construction, and marine industries.

- Q: Can fiberglass fabric be used for reinforcement in water purification tanks?

- Indeed, fiberglass fabric proves to be a valuable asset when it comes to reinforcing water purification tanks. Renowned for its remarkable strength-to-weight ratio and long-lasting nature, fiberglass fabric stands as an ideal choice for fortifying tanks that endure perpetual water exposure. By bolstering the tank's structure, it effectively safeguards against deformation or collapse caused by the water's weight or external pressures. Moreover, fiberglass fabric's resistance to corrosion and chemicals guarantees its integrity, preventing any potential water contamination throughout the purification procedure.

- Q: Are fiberglass fabrics resistant to moisture or humidity?

- Yes, fiberglass fabrics are highly resistant to moisture and humidity. This is because fiberglass itself is made from fine fibers of glass, which do not absorb water or allow moisture to pass through easily. The structure of fiberglass is non-porous and does not support the growth of mold or mildew, making it an ideal material for applications where exposure to moisture or humidity is common. Additionally, fiberglass fabrics can withstand high levels of moisture without losing their strength or integrity, making them a reliable choice for various industries including construction, marine, and automotive.

- Q: What are the different finishes available for fiberglass fabric rolls?

- There are several different finishes available for fiberglass fabric rolls, each providing unique characteristics and benefits. Some common finishes include: 1. Plain: Plain finish refers to fiberglass fabric without any additional treatment or coating. It offers excellent strength and durability, making it suitable for a wide range of applications. 2. Silicone: Silicone-coated fiberglass fabric rolls are popular due to their exceptional heat resistance and non-stick properties. This finish provides excellent release properties, making it ideal for applications involving high temperatures or sticky materials. 3. Aluminized: Aluminized finish involves applying a layer of aluminum to the surface of the fiberglass fabric. This finish offers excellent heat reflection properties, making it suitable for applications where heat insulation is required. 4. Vermiculite: Vermiculite-coated fiberglass fabric rolls provide enhanced fire resistance and heat insulation capabilities. The vermiculite coating expands when exposed to high temperatures, creating a protective barrier against heat and flames. 5. PTFE: PTFE (polytetrafluoroethylene) coating is often applied to fiberglass fabric to enhance its chemical resistance and non-stick properties. This finish is commonly used in applications involving corrosive chemicals or where easy release is required. 6. PVC: PVC (polyvinyl chloride) coating is applied to fiberglass fabric to provide additional protection against chemicals, oil, and moisture. It also offers increased strength and flexibility, making it suitable for various industrial applications. These are just a few examples of the finishes available for fiberglass fabric rolls. Depending on the specific requirements of an application, there may be additional finishes or combinations of finishes that can be utilized to meet the desired functionality and performance.

- Q: Can fiberglass fabric be used for insulation in nuclear power plants?

- Yes, fiberglass fabric can be used for insulation in nuclear power plants. Its excellent thermal insulation properties, fire resistance, and low thermal conductivity make it a suitable choice for insulating various components and systems in nuclear power plants.

- Q: Can fiberglass fabric be used for reinforcement in pharmaceutical tanks?

- Yes, fiberglass fabric can be used for reinforcement in pharmaceutical tanks. Fiberglass fabric is known for its high strength-to-weight ratio and excellent resistance to corrosion, chemicals, and extreme temperatures. These properties make it an ideal material for reinforcing tanks in the pharmaceutical industry, where the tanks may come into contact with various chemicals and substances. Fiberglass fabric can provide structural support, increase the durability and lifespan of the tanks, and ensure they meet the required safety standards. Additionally, fiberglass fabric is lightweight, making it easier to handle and install in tank applications. Overall, the use of fiberglass fabric for reinforcement in pharmaceutical tanks is a reliable and efficient choice.

- Q: What are the weight options for fiberglass fabric?

- Fiberglass fabric, also known as glass fiber cloth, is available in a variety of weight options to suit different applications. The weight of fiberglass fabric is typically measured in ounces per square yard (oz/yd²) or grams per square meter (g/m²). The weight options for fiberglass fabric can range from as low as 0.5 oz/yd² (17 g/m²) to as high as 32 oz/yd² (1086 g/m²) or even more. The weight of fiberglass fabric determines its thickness, strength, and durability. Lighter weight fiberglass fabrics are often used for applications that require high flexibility and conformability, such as in the manufacturing of circuit boards or for reinforcing and repairing small parts. They are also commonly used in aviation and aerospace industries, where weight reduction is crucial. On the other hand, heavier weight fiberglass fabrics are typically used in applications that require higher strength and impact resistance. These can include boat building, automotive parts manufacturing, construction, and even in the production of bulletproof vests and armor. It is important to note that the weight of fiberglass fabric is just one factor to consider when choosing the right fabric for a specific application. Other factors like weave pattern, finish, and resin compatibility should also be taken into account to ensure optimal performance.

- Q: Is fiberglass fabric resistant to fire?

- Indeed, fire resistance is a notable characteristic of fiberglass fabric. The fabric is crafted by weaving fine glass fibers into a strong fabric. These glass fibers possess a remarkable melting point that renders them highly resistant to catching fire or burning. Moreover, fiberglass fabric is frequently treated with fire-resistant substances or coatings to bolster its fire resistance capabilities. As a result, it is an exceptional choice for various applications that necessitate fire resistance, including protective clothing, insulation materials, and fireproof curtains. Nevertheless, it is imperative to acknowledge that although fiberglass fabric exhibits fire resistance, it is not entirely fireproof and may still experience melting or degradation when exposed to extreme heat circumstances.

Send your message to us

Sewing Fiberglass Fabric FRP Pultrusion Roof Tile Sheets or Panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500M2 m²

- Supply Capability:

- 900M2/Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords