Silicone Impregnated High Temperature Resistance Silica Fiber Cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

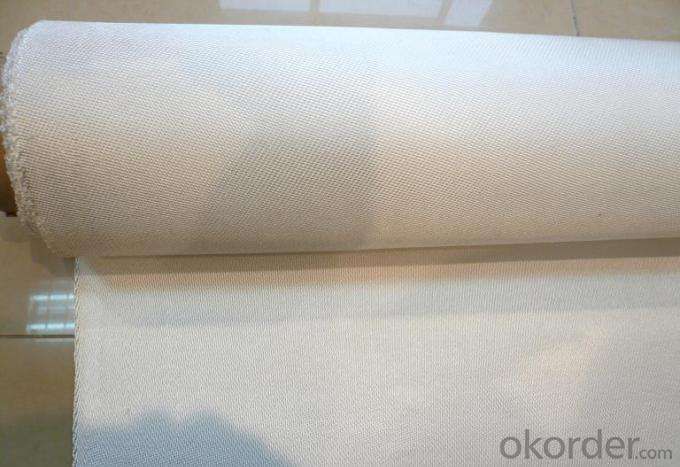

Product Image:

Product Description & Application:

Silica fiberglass cloth is one high-temperature inorganic fiber with the molten temperature nearly 1700 degree Celsius, and the work for a long time at 900 degree Celsius.

Application:

Widely used as heat resistant and ablationresistasant material for rocket,missile and space vehicle;

High-temperature resistant,thermal insulation,refractory material;

Dust collect for high temperature gas;

Liquid filtration;Sound absorbing and thermal insulation for vehicle,motor bicycle;The thermal insulation protective materials for molten liquid filtration.

Product Capability:

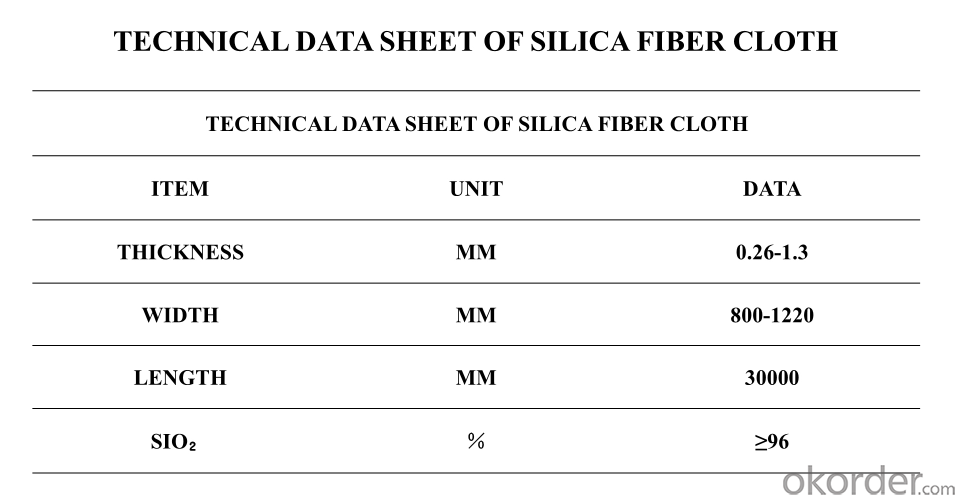

SiO2>=96%;

High temperature resistant,higher thermal insulation,low thermal conductivity;

Thermal stability and chemical stability;

High strength and easy to manufacture;

Nontoxic and harmless to the environment.

Data Sheet:

Fiberglass products:

Fiberglass is a kind of long fiber. It has the advantage of high tensile strength, low thermal conductivity, corrosion resistance and good insulation.The working temperature ranges from 200-1000 degree Celsius. Main products: Fiberglass texturized yarn, cloth, tape, rope, sleeve,mesh,filter cap,friction thread (piece) and fiber netting,composite yarn etc.

- Q: Can fiberglass fabric be used for making flags?

- Absolutely, flags can indeed be made using fiberglass fabric. This splendid material, known for its lightweight nature, durability, and resistance to weather, is perfectly suited for outdoor uses like flags. Moreover, its remarkable strength-to-weight ratio guarantees that the flag will endure even the harshest winds and environmental circumstances. What's more, fiberglass fabric facilitates effortless printing, enabling the creation of vibrant and enduring flag designs. Taking all these factors into consideration, fiberglass fabric emerges as an exceptional option for crafting flags that are not only visually appealing but also long-lasting.

- Q: How is fiberglass fabric repaired?

- Fiberglass fabric can be repaired by using a patching technique. The damaged area is typically cleaned and sanded, and then a suitable adhesive or epoxy resin is applied to attach a fiberglass patch onto the damaged section. The patch is then smoothed out and allowed to cure, ensuring a strong and seamless repair.

- Q: How is fiberglass fabric cut and shaped?

- Fiberglass fabric is typically cut and shaped using a few different methods. One common method is to use scissors or a utility knife to cut the fabric to the desired size and shape. This method is commonly used for smaller or more intricate cuts. For larger cuts or more precise shaping, a technique called "hot knife cutting" is often employed. This involves using a heated blade or wire to cleanly cut through the fiberglass fabric. The heat helps to seal the edges of the fabric, preventing fraying and ensuring a smooth finish. Another method used for shaping fiberglass fabric is molding. In this process, the fabric is laid over a mold or form and then a resin or adhesive is applied to secure it in place. The fabric is then allowed to cure or harden, taking on the shape of the mold. This method is commonly used in the production of fiberglass products such as boat hulls or automotive parts. Overall, the cutting and shaping of fiberglass fabric requires precision and attention to detail. Whether using scissors, a hot knife, or molding techniques, it is important to ensure clean cuts and proper shaping in order to achieve the desired result.

- Q: Are there any specific certifications or standards for fiberglass fabrics?

- Yes, there are specific certifications and standards for fiberglass fabrics. One of the most recognized standards is ASTM D579-04, which establishes the requirements for woven and non-woven fiberglass fabrics used in various applications. Additionally, the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) have established standards such as ANSI/UL 723 and ISO 1182 that evaluate the fire resistance and flammability properties of fiberglass fabrics. These certifications and standards ensure the quality, safety, and performance of fiberglass fabrics in different industries.

- Q: How does fiberglass fabric perform in peel strength?

- Fiberglass fabric typically performs very well in terms of peel strength. Due to the inherent strength and durability of fiberglass, it can withstand significant pulling forces without delaminating or tearing. The adhesive bond between the fiberglass fabric and the substrate is usually quite strong, resulting in high peel strength values. This makes fiberglass fabric an excellent choice for applications where strong adhesion and resistance to peeling are required, such as in composite manufacturing, aerospace, automotive, and construction industries. Additionally, the flexibility and low weight of fiberglass fabric contribute to its overall performance in peel strength, allowing it to conform to various surfaces and maintain its integrity under stress.

- Q: Can fiberglass fabric be sewn?

- Yes, fiberglass fabric can be sewn. However, it is important to note that sewing fiberglass fabric can be challenging due to its stiff and abrasive nature. Specialized sewing equipment and techniques may be required, such as using heavy-duty needles and thread, as well as adjusting the sewing machine settings to accommodate the fabric's properties. Additionally, it is recommended to wear protective clothing and use proper ventilation when working with fiberglass fabric, as the fibers can cause skin irritation and respiratory issues if inhaled.

- Q: Is non-woven fabric and fiberglass all the same?

- Just do it in nonwoven production line products referred to as non-woven fabrics, like eating rice, glutinous rice, rice, black rice, red rice called rice

- Q: How does fiberglass fabric perform in moisture absorption?

- Fiberglass fabric is known for its excellent performance in moisture absorption. Due to its inherent characteristics and composition, fiberglass fabric has a very low moisture absorption rate. The fabric is made from fine fibers of glass that are woven together, creating a tight and dense structure. This structure prevents moisture from easily penetrating the fabric. Compared to other materials such as cotton or polyester, fiberglass fabric has a much lower moisture absorption rate. It does not readily soak up moisture like natural fibers, and it does not retain water for long periods of time. This is advantageous in applications where moisture resistance is important, such as in outdoor or marine environments. The low moisture absorption of fiberglass fabric also helps to maintain its dimensional stability. Even when exposed to high levels of humidity or moisture, the fabric does not swell or warp. This makes it a suitable choice for applications where maintaining shape and integrity is crucial, such as in composite materials or reinforcement applications. Furthermore, the low moisture absorption of fiberglass fabric also contributes to its resistance to mold and mildew growth. Since moisture is not easily absorbed by the fabric, it creates an unfavorable environment for the growth of these microorganisms. This property makes fiberglass fabric a popular choice in applications where moisture resistance and hygiene are important, such as in the manufacturing of medical equipment or food processing industry. In summary, fiberglass fabric performs exceptionally well in moisture absorption. Its low moisture absorption rate, dimensional stability, and resistance to mold and mildew growth make it a reliable choice in various industries and applications.

- Q: Is fiberglass fabric flame resistant?

- Yes, fiberglass fabric is flame resistant. It is made from glass fibers that have been woven into a fabric. The glass fibers have a high melting point, which makes the fabric highly resistant to catching fire or melting. This makes fiberglass fabric a popular choice in applications where flame resistance is important, such as in insulation, protective clothing, and fireproof curtains. However, it is important to note that while fiberglass fabric is flame resistant, it is not completely fireproof. It may still burn if exposed to high temperatures for prolonged periods of time.

- Q: How does fiberglass fabric perform in chemical exposure?

- Fiberglass fabric performs exceptionally well in chemical exposure. Due to its inherent resistance to a wide range of chemicals, it is commonly used in various industries where exposure to corrosive substances is expected. The fabric's composition, typically consisting of glass fibers woven together, provides a strong barrier against chemical attack and degradation. In many cases, fiberglass fabric can withstand exposure to acids, alkalis, solvents, and other corrosive chemicals without experiencing any significant damage or deterioration. This resistance to chemical attack makes it an ideal choice for applications such as chemical storage tanks, pipes, ducts, and equipment linings. Moreover, the fabric's non-reactive nature helps prevent contamination or leaching of chemicals into the surrounding environment, making it a safe and reliable option for handling hazardous substances. Additionally, fiberglass fabric's thermal insulation properties can further enhance its performance in chemical exposure by offering protection against extreme temperatures that may accompany certain chemical processes. However, it is important to note that the specific performance of fiberglass fabric in chemical exposure can vary depending on the type and concentration of the chemical, as well as the duration and temperature of exposure. Therefore, it is always recommended to consult with manufacturers or industry experts to ensure the suitability of fiberglass fabric for a particular application and to determine any necessary precautions or compatibility considerations.

Send your message to us

Silicone Impregnated High Temperature Resistance Silica Fiber Cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords