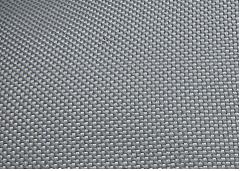

Fiberglass Pvc Roller Blinds Fabric for Composite Fiberglass Fabrics Building

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Composite Fiberglass Fabrics:

1. Description & Keyword:

Keywords: fibergalss fabric, fsk, foil scrim kraft, foil scrim kraft paper, foil scrim kraft facing

Alkaline-resistant fiberglass fabrics as backing brings us a stronger and ductile malleable laminates.

2. Structure & Benefits:

With degradable Mylar film as exposure surface, this products supply better reflection.

Application of Composite Fiberglass Fabrics:

[1]. Pack the air-conditioning outlet

[2]. Could be cut to wrap around the glass wool in different sizes for inserting between the main body and the inner body of the subway wagons, for insulating against temperature and sound .

[3]. As vapor barrier or moisture proof.

Relatived Similar products guide of Composite Fiberglass Fabrics:

FG701: use aluminum foil instead of the aluminum coated film (Mylar film) in FG701.

FGS701: additional layer of 7micron aluminum foil was applied to FGS701

FG701T: self adhesive tape, easy to install, because of the application of pressure sensitive adhesive, two types we supply: one could endure temperature from -10degree centigrade to 60DC, another one could standing from -10DC to 100DC.

- Q: Can fiberglass fabric be used for making carpet backing?

- Yes, fiberglass fabric can be used for making carpet backing. Fiberglass fabric is known for its strength, durability, and resistance to heat and moisture. These properties make it an ideal material for carpet backing as it provides stability and support to the carpet, helping it maintain its shape and structure. Additionally, fiberglass fabric is lightweight and flexible, making it easier to handle and install. It also offers good dimensional stability, preventing the carpet from stretching or shrinking over time. Overall, fiberglass fabric is a suitable choice for making carpet backing due to its strength, durability, and other beneficial properties.

- Q: Are fiberglass fabrics resistant to UV degradation?

- Generally, fiberglass fabrics exhibit resistance to UV degradation. The fabric is manufactured by weaving fine strands of glass together, resulting in a durable and robust material. The glass fibers possess a natural ability to fend off the detrimental impact of UV radiation. Consequently, fiberglass fabrics can endure prolonged exposure to sunlight without experiencing significant deterioration. Nevertheless, it is crucial to acknowledge that the coatings or finishes employed on the fabric might not possess the same level of UV resistance as the fiberglass itself. Consequently, it is advisable to verify the particular product specifications or seek guidance from the manufacturer to ascertain the UV resistance level of a specific fiberglass fabric.

- Q: How is fiberglass fabric used in the production of fire-resistant blankets?

- Fiberglass fabric plays a crucial role in the production of fire-resistant blankets due to its exceptional fire-resistant properties. The fabric is made from woven glass fibers, which are highly resistant to heat and flames. In the production process, fiberglass fabric is first coated with a fire-resistant material or treated with a fire-retardant chemical to enhance its fire-resistant capabilities. This treatment ensures that the fabric can withstand high temperatures and prevent the spread of fire. Fire-resistant blankets are then manufactured by layering multiple sheets of fiberglass fabric together, creating a thick and durable barrier against heat and flames. The blankets are sewn or bonded together to form a single unit, providing maximum protection. When exposed to fire, fiberglass fabric acts as an insulator, reflecting heat and preventing it from reaching the other side of the blanket. This helps to suppress the spread of flames and minimize the risk of burns or injuries. Additionally, fiberglass fabric is lightweight and flexible, making it easy to handle and maneuver during emergency situations. Fire-resistant blankets made with fiberglass fabric are often used in various industries, including firefighting, oil and gas, manufacturing, and construction, to protect workers, equipment, and valuable assets from fire hazards. Overall, the use of fiberglass fabric in the production of fire-resistant blankets ensures a high level of heat and flame resistance, providing effective protection against fire-related risks.

- Q: How is fiberglass fabric used in the production of insulation panels?

- Fiberglass fabric is used in the production of insulation panels as a primary material or as a reinforcement layer. It is typically combined with other materials, such as foam or mineral wool, to create a composite structure that provides thermal insulation. The fiberglass fabric adds strength, durability, and fire resistance to the insulation panels, making them suitable for various applications in construction and industry.

- Q: Can fiberglass fabric be used for making tents?

- Tents can indeed be made using fiberglass fabric. When it comes to constructing tents, fiberglass fabric is a favored option due to its remarkable durability, strength, and resistance to damage. Despite its lightweight nature, it offers exceptional protection against various elements, including wind, rain, and harmful UV rays. Moreover, the fiberglass fabric is fire-resistant and can retain its structural integrity even in extreme temperatures. Furthermore, it is user-friendly and can be effortlessly sewn or welded together to form tent panels. Considering all these exceptional qualities, fiberglass fabric proves to be a trustworthy material for crafting top-notch, enduring tents.

- Q: Can fiberglass fabric be used as a heat shield?

- Yes, fiberglass fabric can be used as a heat shield due to its high resistance to heat and flame. It is commonly utilized in various industries, including aerospace and automotive, to protect against heat and thermal radiation.

- Q: How does fiberglass fabric handle chemicals and solvents?

- Fiberglass fabric boasts outstanding resistance to a broad spectrum of chemicals and solvents. Given its non-reactive nature and remarkable chemical resistance, fiberglass is an ideal material for industries that handle corrosive substances. The composition of fiberglass fabric, comprising woven glass fibers, provides exceptional defense against chemical attacks. It exhibits high resistance to acids, bases, and organic solvents, rendering it suitable for applications in chemical processing plants, laboratories, and oil refineries, where exposure to corrosive chemicals is common. One of the key advantages of fiberglass fabric lies in its ability to maintain physical integrity and mechanical strength even when exposed to various chemicals and solvents. In contrast to other materials that may degrade or become brittle upon contact with certain substances, fiberglass fabric remains stable and durable. This ensures its ability to withstand harsh conditions and perform effectively over extended periods. Another benefit of fiberglass fabric lies in its low permeability to chemicals and solvents. As a result, it acts as a barrier, preventing the passage of harmful substances through its surface. This property proves particularly valuable in applications where containment is crucial, such as storage tanks, pipelines, and chemical-resistant linings. In addition to its chemical resistance, fiberglass fabric also offers other desirable properties. It is lightweight, flexible, and exhibits excellent thermal insulation. These characteristics make it a versatile material applicable in a wide range of situations that require both chemical resistance and structural integrity. However, it is worth noting that while fiberglass fabric is highly resistant to most chemicals and solvents, there are exceptions. Certain potent acids, like hydrofluoric acid, can attack fiberglass and cause degradation. Additionally, prolonged exposure to solvents such as acetone or chloroform may lead to fabric swelling or softening. All in all, fiberglass fabric proves to be a reliable and durable material capable of withstanding a wide range of chemicals and solvents. Its excellent chemical resistance, coupled with its other advantageous properties, render it a preferred choice in industries where protection against corrosive substances is paramount.

- Q: Glass fiber cloth and glass fiber?

- Glass fiber is a kind of inorganic nonmetallic material with excellent properties. English name is: glass, fiber or fiberglass. Composition of silica, alumina, calcium oxide, boron oxide, sodium oxide, Magnesium Oxide etc.. It is prepared by high temperature melting, wire drawing, winding and weaving process with glass balls or waste glass as. All kinds of products formed finally, glass fiber monofilament diameter from a few microns to twenty micron, the equivalent of a hair 1/20-1/5, each bundle of fibers are hundreds or even thousands of root root filaments, usually as a reinforcing material of complex materials, electrical insulating materials and insulation materials, circuit board, etc. and widely used in various fields of the national economy

- Q: How is fiberglass fabric dyed or colored?

- Fiberglass fabric can be dyed or colored using various methods. One common approach is to immerse the fabric in a dye bath containing the desired colorant, such as a pigment or dye solution. The fabric is then heated to a specific temperature, allowing the dye molecules to penetrate and bond with the fibers. Another method is printing, where the desired pattern or design is applied to the fabric using specialized dyes or pigments. The fabric can also be colored during the manufacturing process by incorporating colored or pre-dyed fibers. Overall, the specific technique used to dye or color fiberglass fabric depends on the desired outcome and the capabilities of the manufacturer.

- Q: How long does fiberglass fabric typically last?

- Fiberglass fabric possesses a reputation for its durability and longevity, making it a favored choice across various applications. The duration of its lifespan is contingent upon several factors, including fabric quality, exposure to external elements, and maintenance measures. On average, fiberglass fabric can endure for anywhere between 10 to 30 years. However, by implementing appropriate care and maintenance, it is feasible for its longevity to surpass these estimations. Consistent cleaning, prevention of excessive exposure to harsh chemicals or extreme temperatures, and avoidance of physical harm are all instrumental in significantly extending the lifespan of fiberglass fabric. It is crucial to acknowledge that fiberglass fabric can become brittle and compromise its structural integrity over time, particularly when subjected to continuous high temperatures or harsh environmental conditions. Moreover, natural wear and tear can contribute to its eventual deterioration. To guarantee the utmost longevity for fiberglass fabric, it is advisable to adhere to the manufacturer's maintenance and care guidelines. Regular inspections to identify signs of damage or wear, along with immediate repairs or replacements when necessary, can greatly contribute to prolonging the fabric's lifespan.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Fiberglass Pvc Roller Blinds Fabric for Composite Fiberglass Fabrics Building

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords