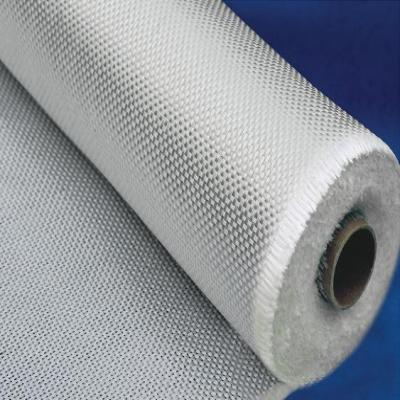

Fiberglass Fabrics - e-glass fiber woven fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 400ton kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

E-glss fiber woven roving is bidirectional fabric made by interweaving direct roving.

Woven Roving are compatible with many resin systems such as polyester, vinyl ester, epoxy and phenolic resins. Woven Roving are high-performance reinforcement widely used in hand lay-up and robot processes for the production of boats, vessels, plane and automotive parts, Pipe, furniture and sports facilities.

2.Characteristics

Top quality woven rovng fabric, E or C glass product

Woven roving fabric is bidirectional fabric made by interweaving direct roving. E-Glass Woven Roving is compatible with many resin systems such as polyester, vinyl ester, epoxy and phenolic resins. E-glass Woven Roving is a high-performance reinforcement widely used in hand lay up and robot processes for the production of boats, vessels, plane and automotive parts, furniture and sports facilities.

Product Features:

1. Warp and weft roving aligned in a parallel and flat manner, resulting in uniform tension.

2. Densely aligned fibers, resulting in high dimensional stability and making handing easy.

3. Good mold ability, fast and complete wet in resins, resulting in high productivity.

4. Good transparency and high strength of composite products.

3.Product Specifications

Items: | Warp Tex | Weft Tex | Warp Density | Woft Density | Weight | Combustible |

Ends/cm | Ends/cm | g/m2 | Content(%) | |||

WRE260 | 600 | 600 | 2.2 | 2.2 | 251-277 | 0.4-0.8 |

WRE270 | 300 | 300 | 4.6 | 4.1 | 248-274 | 0.4-0.8 |

WRE300 | 600 | 600 | 3.2 | 1.8 | 296-328 | 0.4-0.8 |

WRE360 | 600 | 900 | 3.2 | 1.8 | 336-372 | 0.4-0.8 |

WRE400A | 600 | 600 | 3.2 | 3.8 | 400-440 | 0.4-0.8 |

WRE400B | 600 | 900 | 3.2 | 2.3 | 380-420 | 0.4-0.8 |

WRE500A | 1200 | 1200 | 2.2 | 2.0 | 475-525 | 0.4-0.8 |

WRE500B | 1200 | 1750 | 2.0 | 1.6 | 495-545 | 0.4-0.8 |

WRE500T | 1200 | 1200 | 2.2 | 2.2 | 500-554 | 0.4-0.8 |

WRE550 | 1530 | 1200 | 2.0 | 2.0 | 520-570 | 0.4-0.8 |

WRE580 | 1200 | 1200 | 2.6 | 2.2 | 550-610 | 0.4-0.8 |

WRE600B | 2200 | 1200 | 2.0 | 1.6 | 600-664 | 0.4-0.8 |

WRE600C | 1290 | 1290 | 2.8 | 2.0 | 588-650 | 0.4-0.8 |

WRE600D | 1530 | 1530 | 2.0 | 2.0 | 580-642 | 0.4-0.8 |

WRE800A | 1200*2 | 1200*2 | 2.0 | 1.5 | 800-880 | 0.4-0.8 |

WRE800B | 2400 | 2400 | 2.0 | 1.6 | 820-908 | 0.4-0.8 |

WRE800C | 1750 | 1750 | 2.8 | 2.0 | 800-880 | 0.4-0.8 |

WRE800D | 1200*2 | 1530*2 | 2.0 | 1.2 | 806-890 | 0.4-0.8 |

WRE800T | 2400 | 1750 | 2.0 | 2.0 | 790-870 | 0.4-0.8 |

WRE1200A | 4000*2 | 4400 | 0.8 | 1.4 | 1190-1320 | 0.4-0.8 |

WRE1200B | 2400*2 | 2400*2 | 1.4 | 1.2 | 1190-1310 | 0.4-0.8 |

4.FAQ

Packaging & Delivery

Packaging Details: | Poly bag, then loading into carton box |

Delivery Detail: | 20 days after confirm order |

- Q: How does fiberglass fabric compare to carbon fiber fabric?

- Fiberglass fabric and carbon fiber fabric are materials that are widely used in different industries because of their exceptional strength and durability. However, there are distinct differences that set them apart. One major difference lies in their composition. Fiberglass fabric is made by weaving together fine strands of glass, while carbon fiber fabric is composed of tightly woven thin strands of carbon atoms. This fundamental dissimilarity in composition leads to variations in their mechanical properties and performance. In terms of strength, carbon fiber fabric surpasses fiberglass fabric in tensile strength. It is renowned for its stiffness and light weight, making it highly sought after for applications that require a high strength-to-weight ratio. Carbon fiber is commonly utilized in aerospace, automotive, and sports industries where lightweight yet strong materials are essential. Conversely, fiberglass fabric provides good tensile strength but is generally less robust than carbon fiber. However, fiberglass fabric is known for its excellent impact resistance and ability to withstand high temperatures better than carbon fiber. This makes it suitable for applications where heat and impact resistance are important, such as insulation, boat building, and electrical insulation. Another significant difference between these two fabrics is their cost. Carbon fiber fabric is significantly more expensive than fiberglass fabric due to the complexity and cost of the manufacturing process involved. On the other hand, fiberglass fabric is more readily available and easier to produce, making it comparatively more affordable. Furthermore, carbon fiber fabric has a distinct appearance with its black, glossy finish, while fiberglass fabric is typically white or off-white in color. This aesthetic difference can be a factor in certain applications where visual appeal is important. To sum up, fiberglass fabric and carbon fiber fabric possess unique properties and advantages. Carbon fiber fabric offers superior strength, stiffness, and lightweight characteristics, making it ideal for high-performance applications. Fiberglass fabric, on the other hand, excels in impact resistance and heat resistance, making it suitable for applications where these properties are crucial. Ultimately, the choice between these two fabrics depends on the specific requirements of the intended application, considering factors such as strength, weight, cost, and environmental conditions.

- Q: Can fiberglass fabrics be used for insulation in electrical systems?

- Yes, fiberglass fabrics can be used for insulation in electrical systems. Fiberglass is a commonly used material for insulation due to its excellent thermal and electrical insulation properties. It is a non-conductive material, meaning it does not conduct electricity, which makes it ideal for use in electrical systems where insulation is required to prevent electrical current leakage or short circuits. Additionally, fiberglass fabrics have high temperature resistance, making them suitable for applications in electrical systems that generate heat. The fabric form of fiberglass allows for easy installation and wrapping around electrical components, providing a protective barrier against electrical shocks and preventing heat transfer. Overall, fiberglass fabrics are a reliable and effective choice for insulation in electrical systems.

- Q: How much glass fiber cloth and how much epoxy resin does it take to make a square meter of fiberglass?

- There is a construction personnel operation, proficient and skilled, professional and non professional will is much better. I suggest you try it yourself, it will be better.

- Q: How do fiberglass fabrics perform in terms of breathability for human comfort?

- Fiberglass fabrics generally do not perform well in terms of breathability for human comfort. This is because fiberglass, being made from fine strands of glass, has a dense and tightly woven structure that restricts air circulation. As a result, the fabric does not allow for efficient ventilation and airflow, which can lead to discomfort and increased moisture buildup on the skin. Furthermore, fiberglass fabrics are often used in applications where thermal insulation is required, such as in insulation materials or protective clothing. The insulating properties of fiberglass fabrics can trap heat and moisture, further reducing breathability and potentially causing discomfort to the wearer. It is important to note that there are other fabric options available that offer better breathability for human comfort. Natural fibers like cotton, linen, and bamboo, as well as synthetic materials like polyester and nylon, are often preferred for their ability to allow air to circulate more freely, keeping the body cool and dry. Therefore, if breathability and comfort are top priorities, it is advisable to consider fabrics other than fiberglass.

- Q: How does fiberglass fabric perform in tensile strength?

- Fiberglass fabric performs exceptionally well in tensile strength. It has high tensile strength, meaning it can withstand significant stretching or pulling forces without breaking or tearing. This makes it a popular choice in various applications that require strong and durable materials, such as construction, aerospace, automotive, and marine industries.

- Q: What are the different fiberglass fabric coatings for weather resistance?

- There are several different fiberglass fabric coatings available for weather resistance. One commonly used coating is polyurethane, which provides excellent protection against moisture, UV rays, and temperature fluctuations. Another popular option is silicone, which offers superior resistance to high temperatures and is often used in applications where heat resistance is crucial. Acrylic coatings are also commonly used for weather resistance, as they provide good protection against UV rays and are generally more cost-effective than other options. Additionally, vinyl coatings can be applied to fiberglass fabric to enhance its weather resistance, as vinyl is known for its durability and ability to withstand harsh weather conditions. Overall, the choice of fiberglass fabric coating for weather resistance depends on the specific application and the level of protection required.

- Q: Are fiberglass fabrics resistant to tearing or puncturing?

- Yes, fiberglass fabrics are generally known for their high resistance to tearing and puncturing. This is because fiberglass is made from thin strands of glass fibers that are tightly woven together, creating a strong and durable fabric. The inherent strength of fiberglass makes it highly resistant to tearing, even under significant tension or stress. Additionally, the smooth surface of fiberglass fabrics makes it difficult for sharp objects to penetrate or puncture the material. However, it is important to note that the tear and puncture resistance of fiberglass fabrics can vary depending on the specific construction and thickness of the fabric.

- Q: What is the abrasion resistance of fiberglass fabric?

- Fiberglass fabric possesses a high level of abrasion resistance, making it well-known for its capacity to endure repeated friction and wear without incurring substantial damage. Its sturdy and long-lasting nature renders it suitable for applications that require crucial abrasion resistance, including the production of protective clothing, industrial curtains, and reinforcing materials for composites. The actual level of abrasion resistance in fiberglass fabric may vary depending on its construction, finish, and any additional coatings or treatments applied. Nonetheless, fiberglass fabric is universally acknowledged for its superb resistance to abrasion, resulting in its widespread use in industries that prioritize durability.

- Q: How is fiberglass fabric used in the production of insulation boards?

- The excellent thermal resistance, durability, and fire-retardant properties of fiberglass fabric make it widely used in the production of insulation boards. In the manufacturing process, it serves as a reinforcement material and is combined with a binder, such as resin or adhesive, before being compressed to form the boards. This ensures that the insulation material remains stable and prevents it from shifting or settling over time. Additionally, fiberglass fabric enhances the insulation properties of the boards by minimizing heat transfer. This helps to maintain comfortable temperatures in buildings throughout the year, leading to energy efficiency and reduced heating or cooling costs. Moreover, the fire-retardant characteristics of fiberglass fabric provide an extra layer of protection in insulation boards. It acts as a barrier against flames and reduces the risk of fire-related damage. In summary, fiberglass fabric is essential in the production of insulation boards due to its ability to reinforce structures, provide thermal insulation, and offer fire-resistance. It is a versatile and superior choice for various applications in residential, commercial, and industrial buildings where insulation is required.

- Q: Can fiberglass fabric be used for insulation sheets?

- Yes, fiberglass fabric can be used for insulation sheets.

Send your message to us

Fiberglass Fabrics - e-glass fiber woven fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 400ton kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords