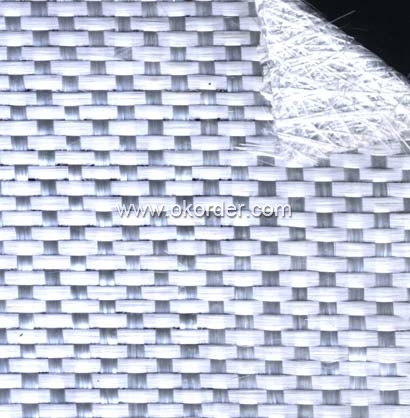

Fiberglass Fabrics Stitch Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- One Pallet kg

- Supply Capability:

- 20 days for 1 x 20FCL kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Fiberglass Stitch Combo Mat

Name: | E-Glass Stitch Combo Mats |

Lead Time: | 20 days for 1 x 20FCL |

MinOrder: | One Pallet |

Package: | Plastic Bag, Carton and Pallet |

Characteristic of Fiberglass Stitch Combo Mat

The special product construction where 0°,90°rovings are parallel aligned without crossing facilities resin impregnation in the layers of chopped strands, resulting in higher productivity and reduced consumption of resins.

The multi-layer structure delivers increased area weight and simplifies the manufacturing process of the composite products, resulting in improve molding productivity and reduced cost.

The composite products feature multi-directional and balanced mechanical properties.

Package of Fiberglass Stitch Combo Mat

Each stitch combo mat is wounded onto a paper tube which has an inside diameter of 73mm, and the roll has a diameter of 260mm. The roll is wrapped up with plastic film, and then packed in a cardboard box or wrapped up with kraft paper. The rolls are to be horizontally placed. For transporation the rolls can be loaded into a container directly or on pallets.

Storage of Fiberglass Stitch Combo Mat

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃-35℃ and 35%-65% respectively.

Standard:ISO 9001

- Q: How does fiberglass fabric perform in fire-resistant applications?

- Fiberglass fabric is an excellent choice for fire-resistant applications due to its inherent properties. When exposed to fire, fiberglass fabric does not burn or support combustion. It has a high melting point, which allows it to retain its structural integrity even at high temperatures. Furthermore, fiberglass fabric does not release toxic gases or smoke when exposed to fire, making it a safe option for fire-resistant applications. This is particularly important in enclosed spaces, as the absence of toxic fumes can help prevent health hazards and promote safe evacuation. In addition to its fire resistance, fiberglass fabric also offers other benefits. It is lightweight and flexible, making it easy to handle and install. It is also highly durable and resistant to chemicals, moisture, and UV radiation. Overall, fiberglass fabric is an excellent choice for fire-resistant applications due to its ability to withstand high temperatures, its non-combustible nature, and its resistance to toxic fumes. It provides a reliable and safe solution for various industries where fire protection is crucial, such as construction, automotive, aerospace, and manufacturing.

- Q: Can fiberglass fabric be used for masks?

- Yes, fiberglass fabric can be used for masks. However, it is important to note that fiberglass particles can be harmful if inhaled, so appropriate precautions should be taken when using fiberglass fabric for mask-making.

- Q: Are fiberglass fabrics resistant to mold or mildew?

- Fiberglass fabrics possess a general resistance to mold or mildew due to their non-porous nature and the fact that they do not foster ideal conditions for the growth of mold or mildew. They find common use in moisture-resistant applications, such as outdoor furniture, boat covers, and shower curtains. It is important to bear in mind, however, that while fiberglass fabrics themselves resist mold or mildew, the presence of organic materials like dirt, dust, or other organic matter on their surface can still provide an opportunity for such growth. Therefore, it is advisable to regularly clean and maintain fiberglass fabrics to ensure their longevity and resistance to mold or mildew.

- Q: Is fiberglass fabric resistant to moisture in marine environments?

- Fiberglass fabric boasts high resistance to moisture within marine settings, rendering it a popular choice for various marine applications. Its exceptional water repellent properties make it highly sought after. The fabric itself is crafted using fine strands of glass fibers, expertly woven together to create a robust and enduring material. These fibers possess a non-absorbent quality, ensuring the fabric's unwavering resistance to moisture, even in the face of harsh marine conditions. This moisture resistance renders fiberglass fabric ideal for safeguarding marine equipment, such as boat covers, sails, and other essential items that necessitate protection from water. Furthermore, fiberglass fabric exhibits resistance to the growth of mold and mildew, further bolstering its suitability for marine environments.

- Q: Can fiberglass fabrics be used for upholstery or furniture applications?

- Indeed, upholstery or furniture applications can utilize fiberglass fabrics. The durability, strength, and resistance to heat and chemicals are renowned attributes of fiberglass fabrics. These remarkable qualities render them appropriate for a wide range of applications, including upholstery and furniture purposes. As a reinforcement material, fiberglass fabrics can enhance the padding or cushioning in furniture, ensuring additional support and prolonged lifespan. Furthermore, as a covering material, fiberglass fabrics exhibit resistance to stains, mold, and mildew. In conclusion, fiberglass fabrics present a versatile and enduring solution for upholstery and furniture applications.

- Q: What are the main characteristics and differences between CEM-3 high thermal conductivity and aluminum substrate? Which kind of board is more advantageous to make lamps and lanterns?

- High thermal conductivity CEM-3 material with high cost performance, and now only genuine, aluminum substrate counterfeit goods more, if from genuine, aluminum substrate has higher heat dissipation performance, but the price is high.

- Q: Is fiberglass fabric suitable for aerospace applications?

- Yes, fiberglass fabric is suitable for aerospace applications. Fiberglass fabric has several characteristics that make it a desirable material for use in the aerospace industry. Firstly, fiberglass fabric is lightweight, which is crucial in aerospace applications as it helps reduce the overall weight of the aircraft or spacecraft, leading to improved fuel efficiency and greater payload capacity. Additionally, fiberglass fabric offers excellent strength-to-weight ratio, providing high tensile strength and structural integrity. This is essential for aerospace applications as it ensures the material can withstand the extreme forces and vibrations experienced during flight. Moreover, fiberglass fabric has good thermal insulation properties, which can help regulate temperature in the aerospace environment and prevent heat transfer between different components. Furthermore, fiberglass fabric is highly resistant to corrosion, chemicals, and moisture, making it suitable for the harsh conditions encountered in aerospace operations. It also exhibits good resistance to fire, which is crucial for safety in the event of an onboard fire. Lastly, fiberglass fabric is relatively cost-effective compared to other materials commonly used in aerospace applications, making it an attractive choice for manufacturers. Overall, the lightweight, strong, durable, and fire-resistant properties of fiberglass fabric make it a suitable material for various aerospace applications, including aircraft structures, interior components, and thermal insulation.

- Q: Are fiberglass fabrics resistant to chemicals?

- Fiberglass fabrics are known for their general resistance to chemicals. They are composed of fine glass fibers woven together to create a fabric. These fibers exhibit exceptional resistance to a wide range of chemicals, including acids, bases, solvents, and oils. As a result, fiberglass fabrics are well-suited for applications in industries such as industrial equipment, chemical processing plants, and automotive parts, where exposure to chemicals is common. However, it should be noted that the level of chemical resistance may vary depending on the specific type of fiberglass fabric and the concentration and duration of exposure to the chemicals. Consequently, it is always recommended to consult the manufacturer or supplier for precise information regarding the chemical compatibility and resistance of fiberglass fabrics.

- Q: Is fiberglass fabric resistant to chemicals in pharmaceutical industry?

- Yes, fiberglass fabric is generally resistant to chemicals in the pharmaceutical industry. Fiberglass is made from glass fibers that are woven together, creating a strong and durable fabric. This fabric is known for its resistance to many chemicals, including those commonly used in the pharmaceutical industry such as acids, alkalis, solvents, and various cleaning agents. Fiberglass fabric is also non-reactive, meaning it does not readily interact with chemicals or release harmful substances. This makes it a suitable choice for applications where chemical resistance is important, such as in the pharmaceutical industry where the fabric may come into contact with various chemicals during manufacturing processes or in cleanrooms. However, it is important to note that the specific type of fiberglass fabric and the specific chemicals involved should be considered to ensure proper compatibility and resistance.

- Q: What is the average thickness of fiberglass fabric?

- Depending on the specific application and manufacturing process, the average thickness of fiberglass fabric can vary. Typically, the thickness of fiberglass fabric ranges from 0.2 millimeters (0.008 inches) to 0.5 millimeters (0.02 inches).

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1969 |

| Annual Output Value | Above US$ 150 Million |

| Main Markets | overseas companies in Hongkong, Canada, South Africa, South Korea, India, Italy, Singapore, France and many other countries and regions. |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 5000,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Fiberglass Fabrics Stitch Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- One Pallet kg

- Supply Capability:

- 20 days for 1 x 20FCL kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords