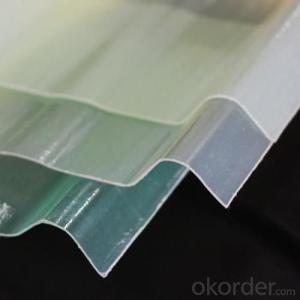

FRP Corrugated Roof Sheets Fiberglass Corrugated Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

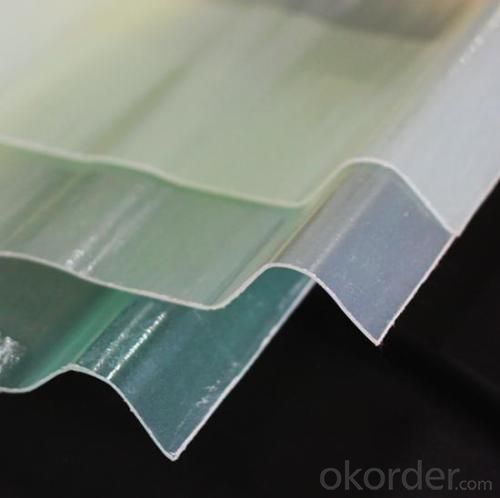

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

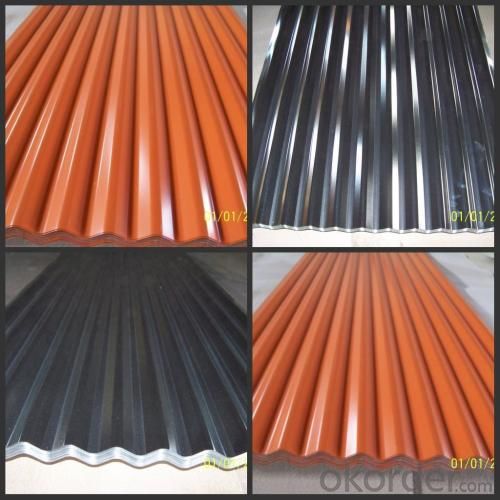

Cold rolled sheet has superb sheet shape and surface quality with good flatness and surface finish. The surface of the cold sheet is clean and bright and easy for coating. The varieties of cold rolled sheet are widely used in galvanized substrates, home appliances, tubing, automobiles, building, enamels and other industries.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATIONS

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q: Do FRP roofing panels expand or contract with temperature changes?

- Yes, FRP roofing panels do expand and contract with temperature changes.

- Q: Can FRP roofing panels be used for commercial warehouses or industrial buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can certainly be used for commercial warehouses or industrial buildings. FRP roofing panels are known for their durability, strength, and resistance to various environmental factors, making them a suitable choice for such applications. They have excellent weathering properties, are resistant to corrosion and chemicals, and can withstand high temperatures. Additionally, FRP panels are lightweight, which can be beneficial for installation and transportation. Overall, FRP roofing panels are a reliable and cost-effective option for commercial warehouses or industrial buildings, providing long-lasting protection and durability.

- Q: Can FRP roofing panels be used for canopies?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for canopies. FRP panels are known for their durability, lightweight nature, and resistance to corrosion and UV rays. These qualities make them ideal for outdoor applications such as canopies. Additionally, FRP panels are available in various thicknesses, colors, and translucencies, allowing for customization to suit the specific design and aesthetic requirements of the canopy. Whether for residential or commercial purposes, FRP roofing panels can provide a sturdy and long-lasting solution for canopy construction.

- Q: Are FRP roofing panels resistant to cracking or splitting?

- FRP roofing panels exhibit exceptional resistance to cracking or splitting due to their composition of fiberglass and plastic resin. This combination yields a robust and enduring material capable of withstanding diverse weather conditions and mechanical strain. The fiberglass reinforcement bolsters the panels' strength and rigidity, rendering them highly resistant to cracking or splitting, even when subjected to substantial loads or impacts. Moreover, the design of FRP roofing panels incorporates flexibility, further minimizing the likelihood of cracks or splits. Ultimately, FRP roofing panels offer a dependable and enduring solution that withstands external forces while maintaining its structural integrity.

- Q: Can FRP roofing panels be used for transportation infrastructure?

- Yes, FRP (Fiber Reinforced Plastic) roofing panels can be used for transportation infrastructure. These panels are lightweight, durable, and corrosion-resistant, making them suitable for various applications such as bus shelters, train platforms, pedestrian bridges, and even road and highway structures. They offer advantages over traditional materials like metal or concrete, including ease of installation, low maintenance requirements, and design flexibility. Additionally, FRP roofing panels can withstand harsh weather conditions and provide excellent insulation properties, making them a viable choice for transportation infrastructure projects.

- Q: Can FRP roofing panels be used for animal shelters?

- Yes, FRP roofing panels can be used for animal shelters. FRP (Fiberglass Reinforced Plastic) panels are durable, lightweight, and resistant to corrosion, making them suitable for use in animal shelters. They provide excellent insulation, are easy to clean, and offer protection from harsh weather conditions. Additionally, FRP panels are cost-effective and can be customized to meet specific shelter requirements.

- Q: Can FRP roofing panels reduce energy costs?

- Yes, FRP roofing panels can reduce energy costs. FRP (Fiberglass Reinforced Plastic) roofing panels are known for their excellent insulation properties, which help to regulate temperature and minimize heat transfer. By reducing heat gain in the summer and heat loss in the winter, FRP roofing panels can significantly reduce the need for heating and cooling, thereby lowering energy consumption and costs.

- Q: Can FRP roofing panels be used for car washes?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for car washes. FRP panels are known for their durability, resistance to corrosion, and ability to withstand harsh weather conditions. These qualities make them suitable for car washes where they may be exposed to water, chemicals, and UV radiation. Additionally, FRP panels are lightweight and easy to install, making them a practical choice for constructing roofs in car wash facilities.

- Q: Can FRP roofing panels withstand high winds?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are designed to withstand high winds. These panels are made from a combination of fiberglass and resin, which provides them with excellent strength and durability. They are engineered to be resistant to bending, warping, and cracking, even in extreme weather conditions such as high winds. FRP roofing panels are often used in areas prone to hurricanes and strong windstorms, where they have proven to be highly effective in protecting buildings against wind damage. They are designed with interlocking mechanisms that provide extra stability and prevent them from being lifted or torn off by strong winds. Additionally, FRP roofing panels are lightweight compared to other roofing materials such as metal or concrete. This light weight reduces the risk of structural damage during high winds as it places less stress on the building's framework. However, it is important to note that the ability of FRP roofing panels to withstand high winds may also depend on other factors such as the installation method, the condition of the roof, and the specific wind load requirements of the area. It is recommended to consult with a professional roofing contractor or follow the manufacturer's guidelines to ensure proper installation and to determine the specific wind resistance capabilities of FRP roofing panels in your particular situation.

- Q: Are FRP roofing panels suitable for agricultural buildings?

- FRP roofing panels are a great fit for agricultural buildings. They offer a range of benefits that make them a popular choice in agricultural applications. Firstly, they are lightweight, durable, and strong, enabling them to handle heavy loads like snow or hail without buckling or collapsing. This is especially important for agricultural buildings as they require a reliable roof to safeguard livestock, equipment, or crops. Moreover, FRP panels are resistant to corrosion, rust, and chemicals commonly found in agricultural environments, such as fertilizers and animal waste. This resistance ensures that the panels will remain intact and functional over time, thus reducing the need for frequent maintenance or replacement. Another advantage of FRP panels lies in their exceptional thermal insulation properties. They can effectively regulate the temperature inside agricultural buildings, keeping them cool in summer and warm in winter. This is particularly beneficial for livestock or crop storage, as it helps create a comfortable and controlled environment. Furthermore, FRP panels are also UV resistant, meaning they can withstand prolonged exposure to sunlight without degrading or discoloring. This is crucial for agricultural buildings that often face harsh weather conditions, including intense sunlight. To sum up, FRP roofing panels are highly suitable for agricultural buildings due to their lightweight yet sturdy construction, resistance to corrosion and chemicals, thermal insulation properties, and UV resistance. These features ensure that FRP panels can provide long-lasting protection and durability in agricultural environments, making them an excellent choice for farmers and agricultural building owners.

Send your message to us

FRP Corrugated Roof Sheets Fiberglass Corrugated Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords