Acrylic Coated Fiberglass Fabric - High Quality Warp Knitting Fiberglass Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

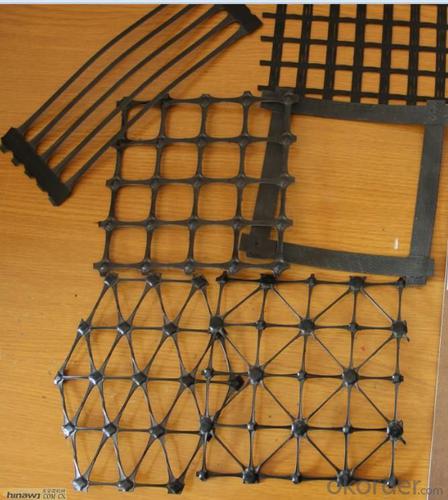

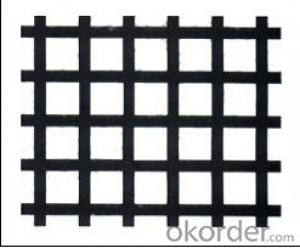

Warp Knitting fiberglass geogrid

The Warp Knitting Fiberglass geogrid selects the excel in synthetic fiber as a raw material,uses the warp knitting oriented structure,latitude and longitude in the fabric to the yarn between not curving condition.

2.Characteristics

Each kind of higher Uygur path,railroad’s soft roadbed enhancement isolation different base earth material.

2. The river bank,the slope of embankment strengthen stably.

3. Each kind of ground strengthens stably.

4. Strengthens the bridge connection surface.

Product Features

1. Geogrid width ranging from 1000mm to 6000mm

2. High intensity, high module, low slow change ,anti-aging , anti-embrittlement, tensile strength to be high strength.

3.Application

Product No. | Stretching ratio(%) | Grid(mm) | Width(mm) | ||

Vertical | Horizontal | ||||

PET20-20 | 13 | 20 | 20 | 12.7x12.7 25.4x25.4 | ±5 |

PET30-30 | 13 | 30 | 30 | 12.7x12.7 25.4x25.4 | ±5 |

PET40-40 | 13 | 40 | 40 | 12.7x12.7 25.4x25.4 | ±5 |

PET50-50 | 13 | 50 | 50 | 12.7x12.7 25.4x25.4 | ±5 |

PET80-80 | 13 | 80 | 80 | 12.7x12.7 25.4x25.4 | ±5 |

PET100-100 | 13 | 100 | 100 | 12.7x12.7 25.4x25.4 | ±5 |

PET120-120 | 13 | 120 | 120 | 12.7x12.7 25.4x25.4 | ±5 |

5.FAQ

Note: The Warp Knitting Polyestergeogrid are available with a width range of 1000mm~6000mm.Other specifications are also available on customer request.

- Q: Can fiberglass fabrics be used for insulation in HVAC ductwork?

- Indeed, insulation in HVAC ductwork can be achieved by employing fiberglass fabrics. The utilization of fiberglass fabrics in HVAC ductwork insulation is widespread, owing to their remarkable thermal attributes and fire resistance. By enveloping the ductwork with a layer of insulation, these fabrics facilitate the reduction of heat transfer and the prevention of energy loss. Furthermore, fiberglass fabrics boast a seamless installation process and the ability to be tailored precisely to meet the unique demands of the ductwork. Moreover, their durability and resistance to moisture render them appropriate for application in both residential and commercial HVAC systems.

- Q: How does fiberglass fabric perform in shear strength?

- Fiberglass fabric exhibits outstanding performance in terms of shear strength. Its composition, consisting of intertwined glass fibers, grants it a remarkable ability to resist forces applied parallel to its surface. The interlocking fibers form a robust and inflexible structure, enabling it to withstand shear stresses and prevent any deformations or failures. Consequently, fiberglass fabric is highly suitable for applications where shear strength plays a crucial role, such as in the creation of lightweight, high-strength composites, the reinforcement of concrete, and the manufacturing of various industrial goods. Furthermore, the shear strength of fiberglass fabric remains largely unaffected by exposure to moisture, chemicals, or high temperatures, ensuring its durability and reliability across a wide range of applications.

- Q: Is fiberglass fabric resistant to tearing?

- Yes, fiberglass fabric is highly resistant to tearing due to its strong and durable nature.

- Q: Can fiberglass fabrics be used for insulation in industrial machinery?

- Yes, fiberglass fabrics can be used for insulation in industrial machinery. Fiberglass fabrics are known for their excellent thermal insulation properties due to their low thermal conductivity. They have high resistance to heat transfer, making them a suitable choice for insulating industrial machinery that operates at high temperatures. Additionally, fiberglass fabrics are non-combustible and have good resistance to chemicals, making them a safe and durable option for insulation in industrial settings. They can effectively trap heat and prevent energy loss, improving the overall efficiency and performance of the machinery. Overall, fiberglass fabrics are a reliable and effective choice for insulation in industrial machinery.

- Q: What does "PCB" mean?

- Mainly based on two reasons: one is the uniform copper foil can have very uniform temperature coefficient of resistance, low dielectric constant, which can make the signal transmission loss is smaller, and the capacitance of different capacitance requirements of high dielectric constant, so as to accommodate higher capacity in a finite volume, why is aluminum capacitor capacitance is smaller, after all is a high dielectric constant! Second, the thin copper foil through the high current temperature rise is small, which for heat dissipation and component life is very good, digital integrated circuit copper wire width is better than 0.3cm, this is also the truth. The finished product plate PCB well is very uniform, soft luster (because the brush on the surface of the solder resist), the naked eye can see, but honestly look at the copper coated base plate can be seen or not many people really, unless you are experienced in the factory inspection.

- Q: Can fiberglass fabrics be custom-designed or printed on?

- Yes, fiberglass fabrics can be custom-designed or printed on. This allows for endless possibilities in terms of creating unique patterns, designs, or even branding on fiberglass fabrics.

- Q: Can fiberglass fabric be used for reinforcement in agricultural tanks?

- Indeed, fiberglass fabric is a suitable option for reinforcing agricultural tanks. Renowned for its impressive strength and durability, fiberglass fabric proves to be an optimal material for reinforcing different structures, including tanks. Its resistance to corrosion, chemicals, and weathering is crucial for agricultural tanks, as they often face harsh conditions. Moreover, the lightweight nature of fiberglass fabric simplifies its handling and installation within tanks. Ultimately, the utilization of fiberglass fabric for reinforcing agricultural tanks can significantly enhance their structural integrity and lifespan.

- Q: Can fiberglass fabric be used for seals?

- Indeed, seals can indeed be made using fiberglass fabric. With their remarkable thermal, chemical, and electrical resistance properties, fiberglass fabrics prove to be highly suitable for a plethora of sealing applications. These fabrics are capable of producing gaskets, seals, and insulation materials that cater to diverse industries such as automotive, aerospace, marine, and electrical. The impressive strength and flexibility of fiberglass fabric enable it to easily mold to uneven surfaces, guaranteeing a trustworthy and long-lasting seal. Moreover, the moisture, oil, and chemical resistance of fiberglass fabric ensures the seals' effectiveness and durability.

- Q: How does fiberglass fabric handle mold and mildew?

- Fiberglass fabric is highly resistant to mold and mildew. Due to its non-porous nature and synthetic composition, it does not provide an ideal environment for mold and mildew to grow. Additionally, fiberglass fabric is often treated with anti-fungal agents during the manufacturing process, further inhibiting the growth of mold and mildew.

- Q: What are the different fiberglass fabric finishes for fire resistance?

- Some common fiberglass fabric finishes for fire resistance include flame retardant, fire retardant, and heat resistant finishes. These finishes are designed to enhance the fabric's ability to resist ignition and slow down the spread of flames in case of a fire.

Send your message to us

Acrylic Coated Fiberglass Fabric - High Quality Warp Knitting Fiberglass Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords