FRP Pultrusion Profiles Fiberglass FRP Panel Sheet Modular Floor Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

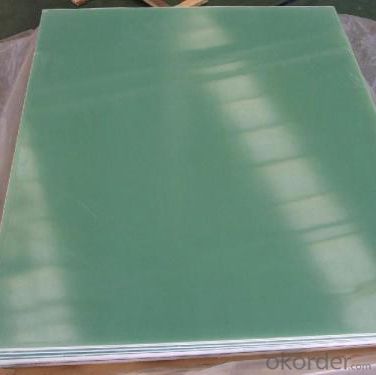

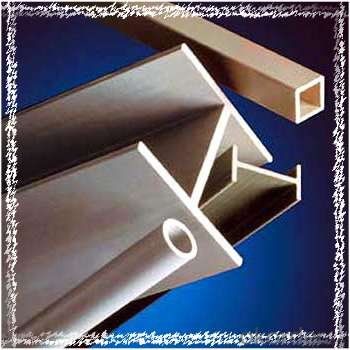

FRP flooring panel is a big size profile which is made by pultrusion technology and in holistic shape, it could form a continuours close plane by unique self-lock structure,which could be used as load structures in various corrosion environments and could replace wood plate, aluminum plate or steel plate etc.

The product could add natural color grit on the surface,which is safe for the anti-slippery,besides it could obtain

the natural appearance and no fadding for a long time.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

SPECIFICATIONS

Product | Item | Unit | Value |

FRP sheet | Thickness | mm | 1.0-2.5 |

Width | mm | <2500 | |

Length | mm | Customized or produce in roll | |

Density | g/cm3 | 1.45 | |

Tensile strength | MPa | 124 | |

Bending strength | MPa | 195.8 | |

Compression strength | MPa | 117 | |

Shear strength | MPa | 108 | |

Impact strength | KJ/m2 | 113 | |

FRP composite sheet | Core veneer thickness | mm | 20-100 |

FR4 thickness | mm | 1.2-2.5 | |

Width | mm | <2500 | |

Length | mm | <8000 | |

Thermal conductivity | Kcol/m2 | 0.57-0.117 |

PICTURES

- Q: How is FRP pultrusion different from other manufacturing processes?

- FRP pultrusion is different from other manufacturing processes in its unique method of producing fiber-reinforced polymer (FRP) profiles. Unlike traditional processes like extrusion or injection molding, pultrusion involves pulling continuous fibers through a resin bath and then into a heated die, where they are cured and shaped into the desired profile. This continuous and automated process allows for the production of strong, lightweight, and corrosion-resistant FRP profiles with consistent mechanical properties. Additionally, pultrusion enables the incorporation of various fiber orientations and resin systems, making it highly versatile for customized applications.

- Q: What are the characteristics of FRP products?

- Good electrical performanceIt is a good insulating material used for making insulators. High dielectric protection can be maintained at high frequencies. Microwave permeability is good, and has been widely used in radome.

- Q: Are FRP pultrusion profiles resistant to biological growth, such as mold or mildew?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to biological growth, including mold and mildew. FRP materials are inherently non-porous, making it difficult for microorganisms to attach and grow on their surface. Additionally, FRP pultrusion profiles are typically manufactured using a combination of resin and glass fibers, which are both naturally resistant to biological growth. Unlike traditional materials such as wood or metal, FRP does not provide an ideal environment for mold or mildew to thrive. The smooth and non-porous surface of FRP profiles prevents moisture absorption, which is essential for the growth of microorganisms. Furthermore, FRP materials do not contain organic compounds that can support the growth of mold or mildew, making them highly resistant to biological degradation. In applications where resistance to biological growth is crucial, FRP pultrusion profiles offer a significant advantage over alternative materials. They are commonly used in environments with high humidity, moisture, or exposure to water, such as marine, agricultural, or wastewater treatment facilities. Additionally, FRP profiles are frequently employed in indoor applications where mold or mildew growth can be a concern, such as in sanitary areas or food processing plants. Overall, FRP pultrusion profiles provide excellent resistance to biological growth, including mold and mildew. Their non-porous nature, combined with the inherent resistance of the materials used in their manufacturing, make them a durable and long-lasting solution in environments where microbial growth is a potential issue.

- Q: Are FRP pultrusion profiles resistant to earthquakes?

- FRP pultrusion profiles possess various benefits in terms of earthquake resistance. The unique properties of FRP materials, such as their high strength-to-weight ratio, flexibility, and damping characteristics, contribute to their ability to withstand seismic events. Moreover, FRP pultrusion profiles exhibit exceptional fatigue resistance, which is particularly important during earthquake-induced vibrations and aftershocks. One major advantage of FRP pultrusion profiles is their lightweight nature. In comparison to traditional building materials like steel or concrete, FRP profiles are significantly lighter, resulting in a reduced overall structure mass. This reduction in weight helps minimize the inertia forces exerted on the building during an earthquake, thereby lowering the potential for damage. Furthermore, FRP materials possess high flexibility and ductility, enabling them to deform and absorb energy during seismic events. This flexibility assists in distributing the seismic forces more evenly throughout the structure, reducing localized stress concentrations and enhancing the overall resilience of the building. Additionally, the damping characteristics of FRP contribute to dissipating the energy generated by an earthquake, providing further protection to the structure against damage. However, it is important to acknowledge that the earthquake resistance of any structure depends on various factors, including the design, construction, and adherence to relevant building codes and regulations. To ensure the FRP pultrusion profiles are appropriately integrated into the structure to withstand the anticipated seismic forces, proper engineering analysis and design must be employed. In conclusion, while FRP pultrusion profiles offer distinct advantages in earthquake resistance, their effectiveness in safeguarding against seismic events relies on the implementation of proper design and construction practices. It is crucial to collaborate with experienced professionals and adhere to established guidelines to ensure optimal performance and protection of FRP structures during earthquakes.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- FRP pultrusion profiles exhibit exceptional durability against wear and abrasion due to the integration of reinforcing fibers, predominantly glass or carbon, and a plastic resin matrix. This combination results in a highly robust material that can endure rigorous utilization. Moreover, the pultrusion process guarantees a uniform composition, with fibers uniformly dispersed throughout the profile, thereby augmenting its resistance to wear and abrasion. Furthermore, FRP pultrusion profiles can be customized with specific additives or surface treatments to further heighten their ability to withstand wear and abrasion, rendering them suitable for diverse applications across industries such as construction, transportation, and marine.

- Q: Can FRP pultrusion profiles be used in agricultural structures?

- Yes, FRP pultrusion profiles can certainly be used in agricultural structures. They offer several advantages such as high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various applications in the agricultural industry. These profiles can be used in structures like greenhouse frames, livestock enclosures, support beams, fencing, and other agricultural infrastructure.

- Q: What are the quality control measures for FRP pultrusion profiles?

- To ensure the desired standards are met, a series of steps and processes are involved in quality control measures for FRP pultrusion profiles. These measures encompass: 1. Inspection of raw materials: The initial step involves verifying the quality of the raw materials used in the pultrusion process. This entails assessing the properties and specifications of components such as fiberglass, resin, additives, and others. 2. Control of the process: Throughout the pultrusion process, it is crucial to monitor and control various parameters. This includes maintaining consistent temperature, pressure, and resin content during impregnation, forming, and curing stages. 3. Testing of samples: Regular sampling is conducted during production to evaluate profile quality. Mechanical properties, dimensional accuracy, and surface finish are tested to ensure they align with the required standards. 4. Visual examination: Each profile undergoes visual inspection to identify any defects, such as cracks, voids, delamination, or surface imperfections. This examination aids in detecting irregularities that may impact the profiles' structural integrity or aesthetics. 5. Mechanical assessment: Profiles are subjected to mechanical testing to evaluate strength, stiffness, and other mechanical properties. Flexural, tensile, impact, and compression tests are conducted, comparing the results to specified requirements to determine compliance with necessary standards. 6. Documentation of quality: Proper documentation is maintained throughout the manufacturing process, encompassing records of raw material specifications, process parameters, test results, and inspection reports. This ensures traceability and serves as a reference for quality assurance. 7. Non-destructive testing: In addition to mechanical testing, non-destructive techniques like ultrasonic testing or X-ray inspection may be employed to identify internal defects or inconsistencies without causing damage to the profiles. 8. Quality audits: Regular internal and external audits are performed to evaluate the effectiveness of quality control measures and ensure adherence to relevant industry standards and regulations. By incorporating these quality control measures, manufacturers can guarantee that FRP pultrusion profiles meet the necessary specifications, resulting in dependable and high-quality products.

- Q: Are FRP pultrusion profiles resistant to chemicals used in mining operations?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemicals commonly used in mining operations. The composite material used in FRP pultrusion profiles is inherently corrosion-resistant and can withstand the harsh chemical environment typically encountered in mining. Additionally, FRP pultrusion profiles offer excellent resistance to acids, alkalis, solvents, and other chemicals, making them a durable and reliable choice for mining applications.

- Q: Can FRP pultrusion profiles be used in electrical insulation applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in electrical insulation applications. FRP profiles offer excellent electrical insulation properties, making them suitable for a wide range of electrical applications. The high dielectric strength of FRP materials ensures that electrical currents are effectively contained within the desired pathways, preventing leakage and electrical hazards. Additionally, FRP profiles possess low electrical conductivity, reducing the risk of electrical shorts and improving overall safety in electrical insulation applications. The non-magnetic nature of FRP materials is also advantageous, as it eliminates the possibility of electromagnetic interference (EMI) in sensitive electrical systems. Furthermore, FRP pultrusion profiles are lightweight, corrosion-resistant, and have a long service life, making them a cost-effective and durable solution for electrical insulation applications.

- Q: Can FRP pultrusion profiles be used in the construction of oil storage tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of oil storage tanks. FRP pultrusion profiles offer several advantages in this application. Firstly, FRP is highly resistant to corrosion, which is crucial for oil storage tanks as they are constantly exposed to harsh environmental conditions and the corrosive nature of oil. This makes FRP pultrusion profiles a suitable alternative to traditional construction materials like steel, which is prone to corrosion and requires frequent maintenance. Additionally, the lightweight nature of FRP pultrusion profiles makes them easier to handle and install compared to heavy steel components. This reduces construction time and costs, making FRP an attractive option for oil storage tank construction. Furthermore, FRP pultrusion profiles offer excellent strength and durability, ensuring the structural integrity of the oil storage tanks. The material's high strength-to-weight ratio allows for efficient load-bearing and structural performance. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in tank design and construction. The pultrusion process enables the production of complex shapes and sizes, providing engineers with the ability to optimize the tank's design for maximum efficiency. Lastly, FRP is non-conductive and has high electrical resistance, making it a safe choice for oil storage tanks. This eliminates the risk of electrical hazards that may occur in tanks constructed with conductive materials. In conclusion, FRP pultrusion profiles can indeed be used in the construction of oil storage tanks, offering numerous advantages such as corrosion resistance, lightweight construction, high strength, design flexibility, and electrical safety.

Send your message to us

FRP Pultrusion Profiles Fiberglass FRP Panel Sheet Modular Floor Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords