Self priming 8 inch Centrifugal sewage diesel pump with trailer

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Introduction

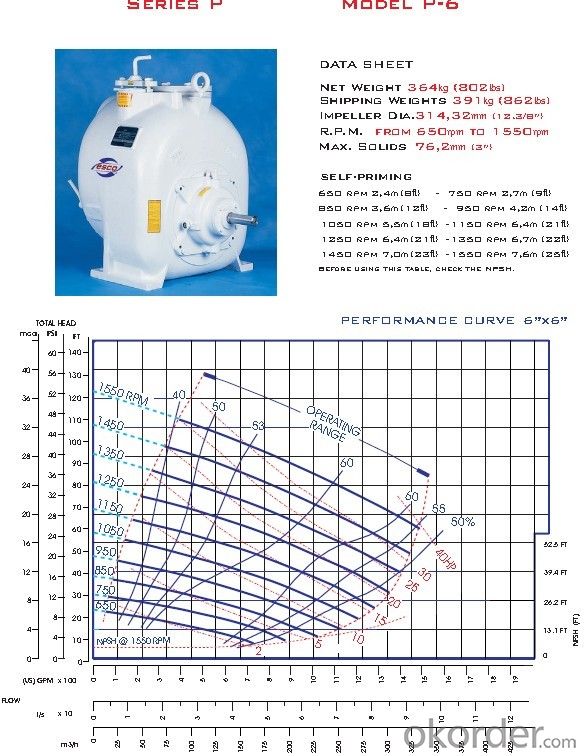

Main datas:

Capacity( flow rate) : 40-600 m3/h

Head :4-34 m

Speed:650 ~ 1500 rpm

Impeller diameter:375 mm

Pump weight: 581 kg / 634 kg

Power: 7.5 ~ 75 hp

Advantage :

Big pump body pass 31.75mm solid ,high suction head 7.6 m

Convenient repair and clean (a person ten minutes)

Removable cover plate ,replaceable wear plate

OEM ,L/C ,TT ,O/A ,D/P,D/A and so on

CE ,TUV .ISO

NAME:Self priming 8 inch Centrifugal sewage diesel pump with trailer

Standard Self-Priming pump units are available for Solids Handling or Clear Liquid service. Typical mounting configurations are Engine Driven for Skid or Trailer Mounted packages and Frame Mounted Electric Driven. Pumps also are available in a variety of different metallurgies.

1) Main Character

1.Beautiful shape and fine structure,reliable performance.

2.With strong capacity of delf priming, no need to equip with flap valve.

3.Non-clog, and with powerful capacity of passing big solid..

4.The hole can make sure that stronger sewage can be cleaned quickly when pump is jammed.

5.The unique lubrication oil mechanical seal cavity makes the performance more reliable.

6.Special check valve structure can make the pump working quickly.

7. When working, the gas and liquid works together .

8. Low rotary speed,reliable operation,long time usage, easy to maintenance.

9.Advanced pressure protector make pump the pump work safe.

2) Application Area

1. Municipal project, sewage project, instruction project.

2.Uptown,hospital, hotel sewage transportation.

3.Classification of municipal sewage factory treatment and concentrate system engineering.

4. Factory and contaminated water delivery.

3) Industries Served

♦ Construction | ♦ Industrial | ♦ Municipal |

♦ Agricultural | ♦ Mining | ♦ Dewatering |

♦ Industrial Waste | ♦ Sewage | ♦ Oil Field |

♦ Petrochemical | ♦ Paper Mills | ♦ Processing |

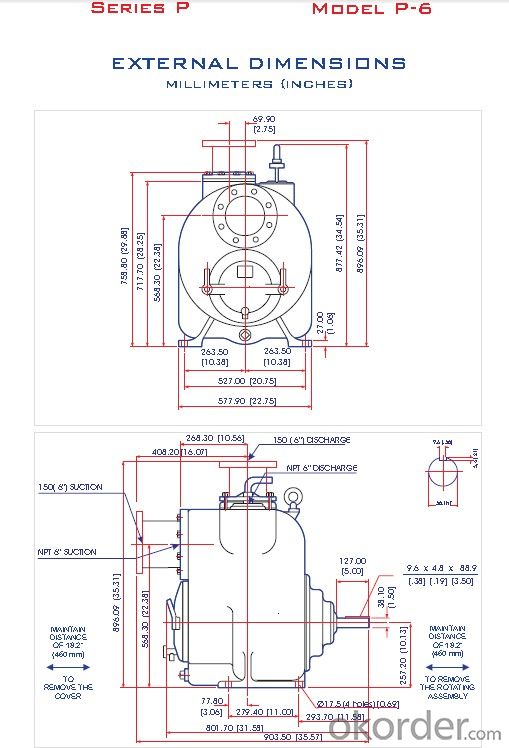

4)Parameter

| 1.Inlet/Outlet | 2''(50mm), 3''(75mm), 4''(100mm), 6''(150mm), 8''(200mm), 10''(250mm), 12''(300mm) | |

| 2.Impeller Diameter | 158.74mm-457.2mm | |

| 3.Rotary Speed | 550RPM-2150 RPM | |

| 4.Flow Rates | 8m3/h-1275m3/h | 20GPM-5500GPM |

| 5.Head | 6m-63m | |

| 6.Horsepower | 1HP-125HP | |

| 7.N.W | 92KG-998KG | |

| 8.G.W | 114KG-1066KG | |

| 9.Solid Passing | 20.63mm-76.2mm | |

| 10.Material | Cast Iron, ADI, CD4MCU, 316 SS, Alloy 20, C276. | |

| 11.Diesel Driving | Water cooled or air cooled | |

| 12.Method of Connection | Self-priming pumps are available as basic units or may be flex-coupled, V-belt driven or engine mounted. | |

| 13.Drive Variation | Cummins, Deutz, Ricardo, Perkins or Chinese Diesel, Electric Motor | |

| 14.Skid Mounted on Trailer | 2 or 4 wheels Trailer/Trailor,Cart | |

| 15.Package | Exporting plywood case | |

| 16.Certification | CE , ISO9001:2008 ,TUV | |

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Prameter

5) Mounting Configuration

♦ Frame Mounted

♦ Base Mounted Electric Driven

♦ Engine Driven SAE Mounted

♦ Engine Driven Skid or Trailer Packages

♦ Horizontal or Vertical V-Belt Driven

Samply available: 7~10days.

Qty: 1pc, only pump head is provided.

Price: US$100~200

OEM is welcome

OEM expierence: more than 10 years.

Countries: Germany, U.S.A, Spain, Italy, United Kingdom etc

Warranty: the whole pump is guaranteed within 1 year, the pump's spare parts are guranteed for 3 months from the date of delivery.

For more information, please do not hesitate to contact me.

The information should be including inquiry as following:

1.Pump's flow rate

2.Pump's Head (Pressure)

3.Driven Mode: By electric motor or diesel engine or bare shaft etc

4.Power and rotary speed

5.Suction lift for self priming pump

6.Temperature of liquid if you can provide

Upon the receipt of the pump's parameter, we can send our quotation to you within 24 hours.

Or the condition of pump station would be provided.

♦FAQ:

1. Q: Can I know more about your products?

A: Pls view our website: www.lanco.cc.

2. Q: What’s your MAQ of this item?

A: 1~2PCS

3. Q: What is the lead time?

A: 10~30 days after receiving your payment,depends on pumps.

4. Q: where is your loading port?

A: Ningbo, China port

5. Q: Are you a manufacturer or trading company

A: We are a manufacturer specialize in water pump and other pumps more than 20 years.

For more information, please contact me.

Components Display

- Q: A residential building with a floor height of 11 stories and a roof height of 33 meters. The height of the water tank is 37.7 meters. The basement is -3.3 meters, only set fire hydrant, fire pump only consider the indoor fire water, fire flow should be 10l/s. Now select a fire pump, concrete should be much traffic, big head, flow determine how? How to determine the head, I hope to say some more detailed, thank you, and there is to explain this question, why is the fire pump lift 120?. Thank you

- According to the water quantity form fire flow water supply system fire safety in high-rise building fire hydrant pump lift is 10L/s, accurate algorithm is to say after a simple calculation with each indoor hydrant flow is two 5L/s bolt so to get the most unfavorable point for the calculation unit to calculate the minimum requirements, with the most unfavorable point suppository pressure specifications 0.07MPa, partial loss of the most unfavorable line and the line (according to the equivalent length) and loss (according to the material resistance coefficient), and finally the pump head loss of gravity difference. But we just calculate the construction elevation difference multiplied by 110% to 120% to determine the head {there is a need to know is: conversion head (m), (kg) and MPa kg 1MPa=10 kg = 100m is the vertical water column on unit area pressure conversion

- Q: What is the minimum continuous flow of a pump?

- Quality solutionsMinimum flow of pump, minimum continuous flow of pumpIn order to ensure the proper use of the pump and the normal operation of the pump manufacturer will indicate the minimum pump in the sample of the continuous operation flow, the correct selection or use to warn or instruct users. According to the provisions of the API standard, the minimum continuous flow into the minimum continuous stable flow and continuous flow. Most small thermal limit(1) the minimum continuous stable flow.API standard specifies the minimum continuous stable flow refers to the vibration limit does not exceed the standard set by the pump can work normally. The minimum flow pump at small flow rate, there will be noise and vibration increase, API of this provision is to ensure that the service life of the pump, avoid due to improper operation of the pump caused by the adverse effects.

- Q: What are the basic technical parameters of the pump?

- Two, pump head H head is the unit weight of the liquid pump pumping from the inlet of the pump (pump inlet flange) to the outlet of the pump (pump outlet flange) energy value. Effective energy is a Newtonian liquid through the pump unit is obtained. The N m/N=m, the height of liquid column pumping liquid. Habits referred to as meters. Three, the pump speed is n RPM pump unit time revolutions, represented by the symbol n, the unit is r/min. four, the pump NPSH NPSH NPSH is also called net positive suction head, said main parameters of cavitation performance. Cavitation has been used a h power of five, the power of the pump. And the efficiency of the pump is usually refers to the input power, which is the prime mover on the pump shaft power, it is also known as the shaft power, denoted by P;

- Q: What kind of motor does the hydraulic pump need?

- First count the flow: Q=dn L / minD displacement / revN RPM / minThen calculate the actual power: N=QP/ (60K) kwQ flow L / minP MPa MPaK total efficiency (usually 0.85)

- Q: What is the displacement of the pump? Flow? What is the volume efficiency and mechanical efficiency of the pump?

- Pump flow: the volume of liquid discharged per unit time.(3) volume efficiency of pump: the ratio of actual output flow of pump to theoretical flow rate.

- Q: Why does the centrifugal pump start and close first when the outlet valve is closed?

- The contact is burned out, the bond and so on the accident, therefore closes the outlet valve, starts the electric machinery, at this time the electric machinery belongs to the no-load current movement, greatly reduces the big current impact

- Q: Pump operator's responsibility 10Sharing the rules, responsibilities, etc..

- 7., master the knowledge of concrete mix ratio, strictly forbid to add water to the pump at will.8., concrete mixing and workability, gravel diameter is too large, effectively refuse to pump.9. when the delivery pump fails, it can analyze the cause and quickly eliminate the trouble.10. pump complete, you must clean the pump body and pressure pipe residual.11. complete other temporary work assigned by the leader.

- Q: What is the main difference between SK water ring vacuum pump and 2BV water ring vacuum pump?

- SK vacuum pump is a single-stage water ring vacuum pump, vacuum pump and motor separation, coupled with couplings, vacuum relatively low.

- Q: Why does the centrifugal pump start with a closed valve and the axial pump starts with an opening valve?

- Because the characteristic curves of the two are different.The power of centrifugal pump decreases with the decrease of flow rate. When the flow rate is zero, the power is minimum, so the centrifugal pump is started with a closed valve.

- Q: What are the failures and causes of the replacement of the fuel pump assembly?

- Gasoline pump is the gasoline from the gasoline tank suction and the gasoline tank has a certain pressure, thereby, it overcome the resistance of the pipeline, pipeline and fuel filter into the carburetor float chamber or electronically controlled injection engine in the guide frame.

Send your message to us

Self priming 8 inch Centrifugal sewage diesel pump with trailer

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords